Navigation

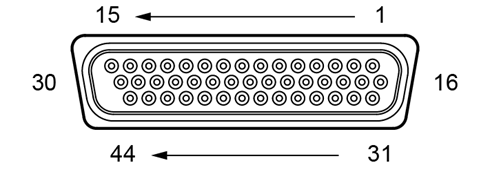

Machine I/O (44W HDD socket)

The machine I/O is connected into this socket and connections made by the CMM installer using the pinout guide below. A mating connector for the machine I/O socket is provided within the SPA3-2 kit.

| Pin number | Function | Pin number | Function |

|---|---|---|---|

| 1 | External I/O 24 V supply | 23 | Crash |

| 2 | /Enable air solenoid/ (low to enable air) | 24 | Reserved |

| 3 | /Axis 0 brake/ (low to release brake) | 25 | Axis 0 positive outer limit |

| 4 | /Axis 1 brake/ (low to release brake) | 26 | Axis 0 negative outer limit |

| 5 | /Axis 2 brake/ (low to release brake) | 27 | Axis 1 positive outer limit |

| 6 | Uncommitted output 0 | 28 | Axis 1 negative outer limit |

| 7 | Uncommitted output 1 | 29 | Axis 2 positive outer limit |

| 8 | Uncommitted output 2 | 30 | Axis 2 negative outer limit |

| 9 | Uncommitted output 3 | 31 | Axis 0 positive inner limit |

| 10 | Uncommitted output 4 | 32 | Axis 0 negative inner limit |

| 11 | Uncommitted output 5 | 33 | Axis 1 positive inner limit |

| 12 | Uncommitted output 6 | 34 | Axis 1 negative inner limit |

| 13 | Uncommitted input 0 | 35 | Axis 2 positive inner limit |

| 14 | Uncommitted input 1 | 36 | Axis 2 negative inner limit |

| 15 | Uncommitted input 2 | 37 | 0 V |

| 16 | Uncommitted input 3 | 38 | /Axis 3 brake/ (low to release brake) |

| 17 | Uncommitted input 4 | 39 | Axis 3 positive outer limit |

| 18 | Uncommitted input 5 | 40 | Axis 3 negative outer limit |

| 19 | Reserved | 41 | Axis 3 positive inner limit |

| 20 | De-clutch | 42 | Axis 3 negative inner limit |

| 21 | Reserved | 43 | Reserved |

| 22 | Low air pressure | 44 | 0 V |

| Shell | Screen |

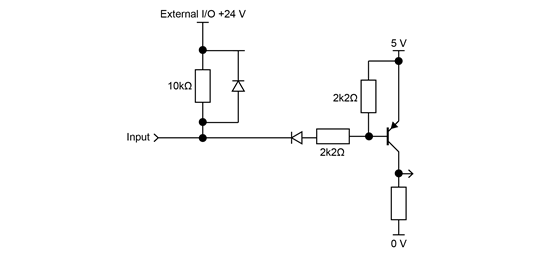

All input pins

Digital input pins are not opto isolated and are internally pulled up to the external I/O +24 V supply by a 10 kΩ resistor.

To activate, the pin must be pulled 'low', below 3 V (e.g. machine I/O 0 V, pin 37 or 44).

To deactivate, the pin must be driven 'high', above 4.2 V (or open circuit).

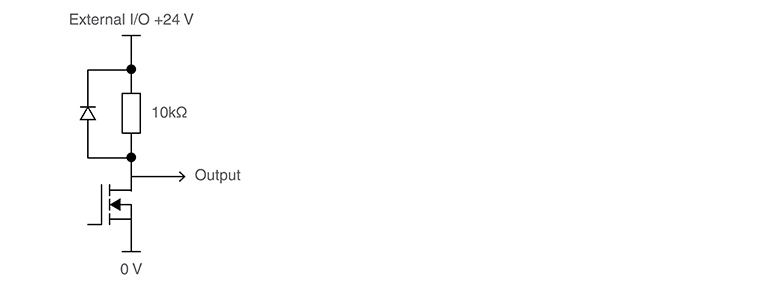

All output pins

All digital output pins have a 10 kΩ pull-up resistor to the external I/O +24 V supply, these output pins are suitable for driving devices in the range +5 V to +24 V and can sink a maximum current of 1 A. If this output is not required, then it should be left as an open circuit.

CAUTION: The output pins are not suitable for direct connection to circuits operating above +24 V.

External I/O +24 V

The external I/O +24 V supply is provided to power external solenoids and solid state limit switches, this can supply a maximum current of 1 A. If higher current is required then a separate power supply must be used.

NOTE: The machine I/O +24 V supply output is shared between the machine I/O connector and the configurable I/O connector.

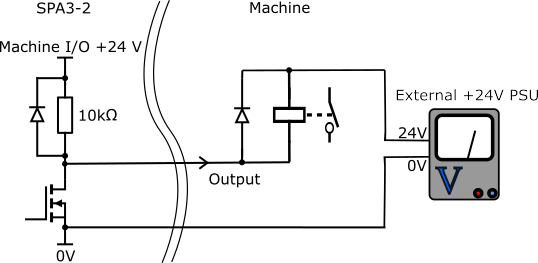

Using a separate +24 V PSU

If higher current is required to supply machine solenoids, relays or limit switches then a separate PSU can be connected.

The following circuit shows how an external PSU is connected to the SPA3-2 for correct operation.

CAUTION: Flyback diodes must be directly fitted to all solenoids and relays when using an external PSU.

Enable air solenoid

An active low signal to engage an air solenoid.

Brake

These outputs (pins 3, 4, 5 and 38) are used to released the CMM axis brakes if fitted. These outputs become low to release the brakes as soon as the CMM servos are engaged.

Uncommitted outputs

These output pins can be configured to the customer's requirements via the UCCsuite software.

Uncommitted inputs

These input pins can be configured to the customer's requirements via the UCCsuite software.

De-clutch

This input on pin 20 should be pulled 'low' to signal to the controller that the CMM's drives are mechanically connected to the moving elements of the machine (i.e. in their normal condition). The input should be open circuit, or held 'high', when the CMM has been temporarily 'de-clutched' from the drive motors to allow manual positioning. The servo system will not drive the motors in this condition and will resume control at the machine's current position when the signal goes 'low'. If this capability is not required the signal should be connected to 0 V or inverted during commissioning.

Low air pressure

The low air pressure signal should be pulled 'low' through a suitable air pressure switch. This input is monitored by the controller and when activated will remove power from the motors by causing a system fatal fault. During the commissioning process it is possible to invert this signal from an active 'low' signal to an active 'high' signal. If this capability is not required the signal should be connected to 0 V or inverted during commissioning.

NOTE: It is strongly recommended to monitor supply air pressure if the CMM is using air bearings and / or a pneumatic counter balance.

Crash

The crash signal is used to inform the SPA3-2 of a collision of the mechanical structure of the machine. Typically this is a sensor that is fitted to the end of the CMM quill and if activated will remove power from the motors by causing a system fatal fault.

During the commissioning process it is possible to invert this signal. If this capability is not required for integration the signal should be connected to 0 V or inverted during commissioning.

Limit switches

The SPA3-2 controller supports both inner and outer limit switches for each of the machine axes. During the commissioning process it is possible to invert these signals. If this capability is not required for integration to the system then they should be connected to 0 V or inverted during commissioning.

Inner limit switches

If an inner limit is activated the UCC system will perform a maximum movement de-acceleration in all axes to a stop and then perform a controlled axis back-off in the opposite direction, as if a trigger event occurred.

Outer limit switches

If an outer limit is activated the UCC system will immediately disengage all servo power to the machine drives and apply the machine brakes. Recovery of this error is only possible by removing the outer limit switch activation (i.e. by moving the machine off of the switch).

0 V

This is the 0 V reference for all of the I/O signals.

NOTE: All input signals can be inverted from active low to active high during the commissioning process, however care should be taken as this may prevent the input being detected in the event of input disconnection or cable break. It is therefore NOT recommended to invert inputs where possible.