CARTO software for precision motion systems

CARTO is Renishaw's powerful software suite for simplifying measurement and analysis of machine tools, motion stages and co-ordinate measuring machines

The CARTO software suite is an advanced digital ecosystem for Renishaw machine calibration and optimisation products. It provides precision measurement and alignment solutions to simplify test set-up, performance and analysis, as well as simplified data management.

Compatible with desktop and mobile devices, CARTO is free to download and supports a seamless workflow for capturing, analysing and correcting errors in motion systems.

Its core features work with Renishaw laser products to collect and analyse data. The optional add-ons extend product capability for compensation and off-axis rotary measurements can be purchased from the Renishaw online store. You can select the appropriate core applications, add-ons or apps based on your specific measurement requirements.

CARTO is built around real-world customer needs. It delivers accuracy, efficiency, and ease of use throughout the machine calibration process, and is regularly updated to meet evolving customer needs.

CARTO for desktop

CARTO software

CARTO software add-ons

Capture

Easily collect measurement data from tests performed with Renishaw's XM-60, XM-600 and XL-80 laser systems, as well as the XR20 rotary axis calibrator with the XC-80 environmental compensator, in a few simple steps:

- Automatically save test methods for repeatability

- Generate part programs for most machine controllers

- Store laser position, environmental data and timestamps

Explore

Analyse and compare data from tests performed with Renishaw laser systems, XR20 rotary axis calibrator and QC20 ballbar with ease:

- Generate reports to international standards (PDF format available)

- Compare historical and positional data

- Tag and filter results for quick access

Compensate

Simplify volumetric compensation and apply geometric error corrections effortlessly with CARTO Compensate:

- Create custom LEC.ren files for your machine

- Perform compensation calculations with minimal user input required

- Export files ready for direct upload to supported controls

Off-axis rotary measurements

Use Off-axis rotary measurement mode to test rotary systems with precision:

- Automatically calculate offset distances

- Generate a test part program

- Remove linear axis angular errors for 'clean' results

CARTO for mobile devices

CARTO Ballbar Connect and CARTO XK20 app are mobile device apps for when you're on the go. Retaining the useability and intuitive interfaces of Renishaw's CARTO software, our apps make calibration and laser measurements quick and easy, with minimal set-up required.

Both apps feature helpful animations and step-by-step guidance to build user confidence when using our laser calibration and optimisation products.

CARTO Ballbar Connect

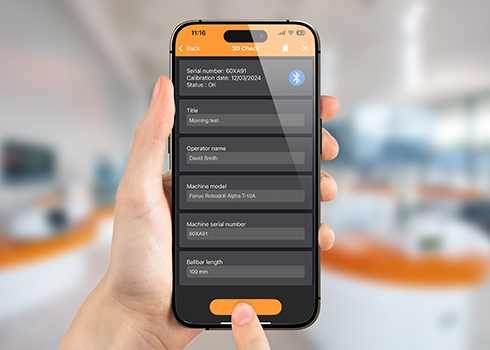

CARTO Ballbar Connect is Renishaw's first smartphone app for the QC20 ballbar, designed for swift and intuitive testing. It features 3D Check, a primary test sequence and runs a quick, static performance assessment on machine tools.

CARTO XK20 app

The CARTO XK20 app delivers a sequential and intuitive user experience to support machine tool builders. It simplifies the process of measuring geometrical features using the XK20 alignment laser system.

Support and compatibility

Browse our library of videos, how-to-guides and downloads. You can also find out more and check your compatibility with supported calibration products.

Machine calibration and optimisation

Find out more about our range of laser interferometer and ballbar measurement products designed to improve the performance of precision motion systems.

FAQs

What operating systems is CARTO supported on?

CARTO is supported on Windows™ 10 (version 1803 or greater) and Windows™ 11. There is no support for macOS®, Linux®, or earlier versions of Windows.

Which calibration products are compatible with CARTO software?

CARTO software is compatible with the XL-80 laser interferometer, the XM-60 and XM-600 multi-axis calibrator, and the XR20 rotary axis calibrator as desktop software. It is also available as an app for the QC20 ballbar and the XK20 alignment laser.

Can I still access the original software that has been superseded by CARTO?

Yes, the full range of our original software is still available and can be found here.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.