What's new?

Renishaw provides regular updates to CARTO software, including new functionality.

A summary of our latest software versions can be found below.

Features in version 4.12

Explore: Improved accuracy for XK10 alignment laser measurements in demanding environments

The data stitch function in CARTO Explore reduces noise on long axis measurements which are often affected by air turbulence. By breaking the measurement into smaller sections and stitching them together, the environmental effects on each section can be reduced, leading to increased accuracy of the overall measurement.

Key features in Capture

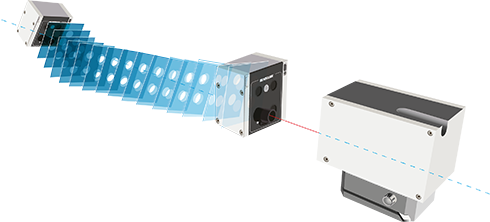

Capture: Off-axis rotary measurement mode

The off-axis rotary measurement mode in the Capture application is a licensed option which allows the XR20 rotary axis calibrator, combined with the XL-80 laser system or XM-60 multi-axis calibrator to capture off-axis measurements in one session.

Capture: improved straightness measurement

Minimise the effects of air turbulence and vibration often observed during straightness measurement when using your XM-60 or XM-600 multi-axis calibrator. Dynamic data fit mode captures a higher density of straightness data in a continuous sweep of the axis.

This method gives a more representative error for the application being measured.

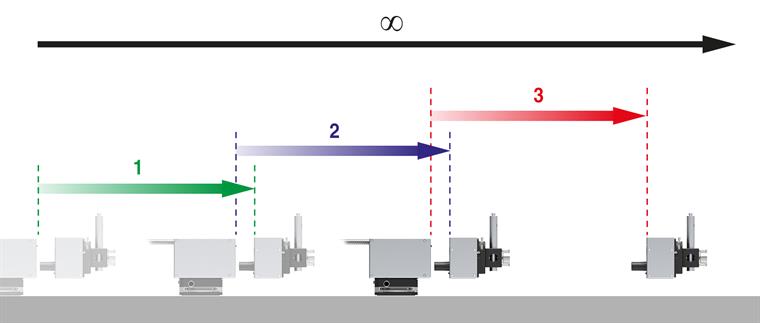

Capture: long range measurement

Unlimited measurement range of your XM-60 or XM-600 multi-axis calibrator. Use dynamic data fit mode in Capture to define sub test methods, create part programs and capture data sets. Sub test data is automatically stitched in Explore for analysis.

Key features in Explore

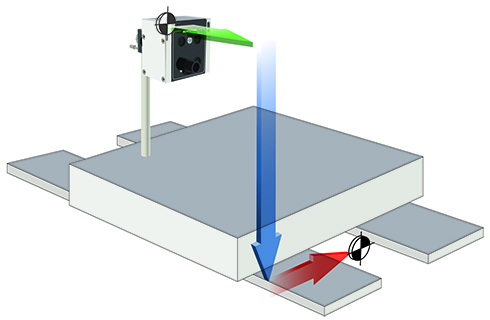

Explore: measure the point of interest

Measurement at the point of interest is often not possible. The location can compromise mounting of the hardware or obstruct the laser beam. The offset readings function in Explore allows the X, Y, Z deviations from the receiver to the point of interest to be entered into the software. Captured data is then recalculated to give the true errors at the source.

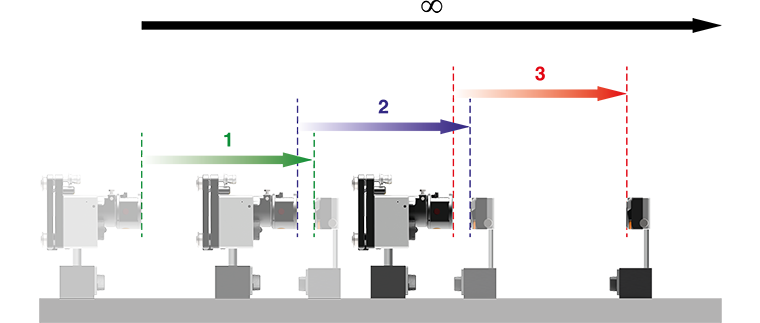

Explore: Data stitch for longer axes measurement

The new analysis-based data stitch function in CARTO Explore allows users of XM-60 and XL-80 laser systems to analyse stitched data to international standards. By adding this function to CARTO Explore, data captured from the XM-60 using the target-based measurement mode can now be easily stitched together and analysed for longer axes.

This added capability enables XL-80 laser system users to break down measurements of longer axes, that are captured in noisy measurement environments, into smaller sections and stitch them together. This reduces the environmental effect on each section and increases the accuracy of the total measurement.

Explore: Error visualisation

Understanding errors and the relationship between the 6 degrees of freedom is not always easy to interpret. The 3D error visualisation feature, with graphical plots, in Explore displays a scalable animation of the measured axis. This allows the user to gain a greater understanding of their measurement and easily demonstrate error against position whilst in the error visualisation mode.

Explore: export to CSV

Gain instant access to your data by exporting single or multiple data sets to Comma Separated Value files (CSV). This allows maximum flexibility to expand your data usage options.

Explore: XK10 straightness and parallelism analysis

XK10 alignment laser data can now be analysed, allowing data manipulation, comparison and parallel straightness functionality within Explore. Data sharing using customised PDF reports is also available.

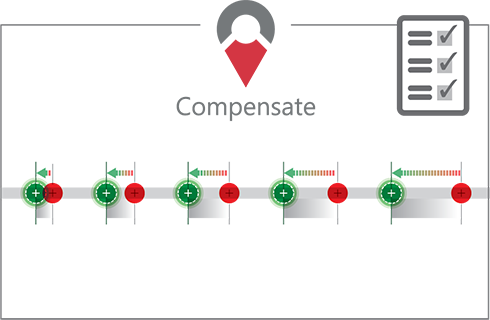

Key features in Compensate

Compensate: machine tool error correction

Mitsubishi M800 Series controls now supported. Provides users with volumetric compensation files in native machine tool language. Minimise machine downtime, maximise profits, optimise cutting performance. Siemens 840D already supported.

Compensate: machine tool error correction

Heidenhain iTNC 530 and Fanuc 30i series controls now supported. Provides users with pitch compensation files in native machine tool language. Minimise machine downtime, maximise profits, optimise cutting performance. Siemens 840D and Heidenhain TNC 640 are already supported.

Find out more about our intuitive

CARTO softwareand CARTO add-ons. Easily access videos, user guides and downloads.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.