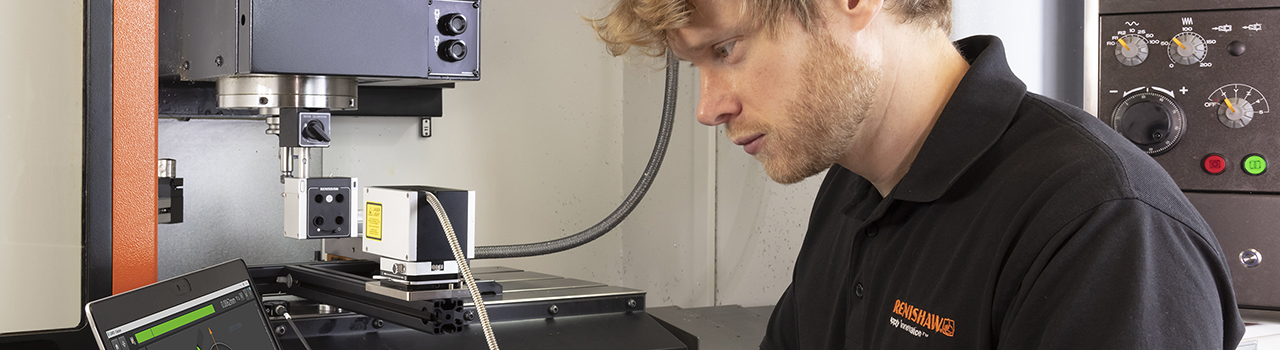

Lasers for 6DoF machine measurement

Addressing and rectifying errors in axis measurements can be a timely and inefficient challenge. This is where reliable laser systems for six degrees of freedom (6DoF) machine measurement becomes essential.

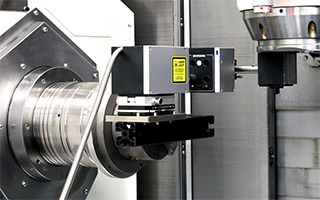

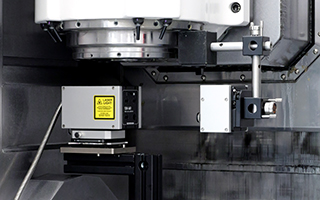

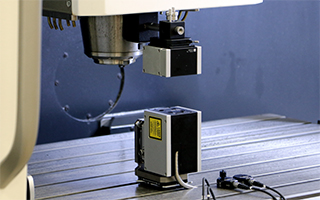

Renishaw's XM-60 multi-axis calibrator measures errors in six degrees of freedom along a linear axis, simultaneously from a single set-up. It uses comprehensive analysis software to investigate the relationship between different error types along axes and monitor the drift of a machine's performance over time. This leads to maximising productivity, efficiency, and output quality in a machine shop.

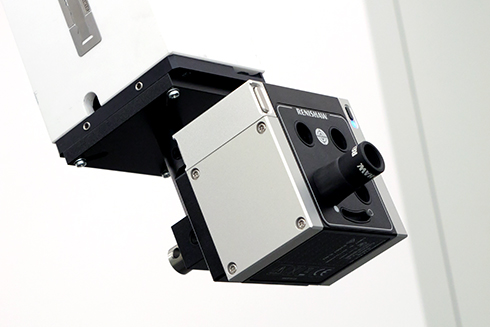

Renishaw's XM-600 multi-axis calibrator delivers the full functionality of the XM-60 system when used with the CARTO software, along with additional capability to communicate with Renishaw's UCC controllers. This makes it ideal for any manufacturing facility that utilises both machine tools and CMMs (Coordinate Measuring Machine).

What is a multi-axis calibrator?

A multi-axis calibrator is an instrument used to calibrate and assess the accuracy of multiple axes in various motion systems and machinery. They are commonly used in applications such as manufacturing, robotics, CNC machines and coordinate measuring machines to maintain the precision and reliability of the equipment.

The XM-60 multi-axis calibrator has been designed by Renishaw to precisely measure errors in six degrees of freedom along a linear axis, simultaneously from a single set-up. When used with an XC-80 environmental compensator, linear measurements are automatically compensated to ensure high accuracy across the full environmental operating range.

For users of volumetric compensation the XM-60 system provides a quick and accurate method of data population. All measurements are made optically allowing use in any orientation.

Why would you use a multi-axis calibrator?

Multi-axis calibrators play a crucial role in industries where precision and accuracy are paramount. Their primary function is to ensure that multiple axes within mechanical systems are accurately calibrated and aligned to guarantee precise movements. In regulated industries, multi-axis calibrators can be used to prove compliance with industry standards and regulations.Regular calibration with versatile multi-axis calibrators, such as the XM-60, allows for quality and reliability of machinery to be maintained with ease. Machine downtime is minimised, reducing the impact on production lines.

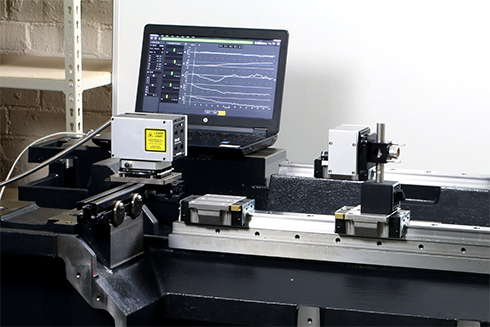

The XM-60 multi-axis calibrator works alongside the intuitive CARTO software for easy capture and analysis of data. A comprehensive range of data manipulation tools allows analysis to meet international standards and individual requirements.

Key benefits

Quick measurement

From a single set-up, linear, pitch, yaw, roll, horizontal and vertical straightness can be measured.

Simple set-up

Easy set-up, automatic sign detection and graphical alignment minimise human errors

.

Details results

Effortlessly capture data with CARTO software to measure, analyse and export machine performance results.

Unique technology

For measurement capability in all orientations with optical roll.

Added value through CARTO software development

Renishaw's CARTO software consists of three applications; Capture to collect laser measurement data, Explore for powerful analysis to international standards and Compensate for quick and easy error correction.

Regular updates add value to the XM-60 system and widen application opportunities.

- The analysis-based data stitch function in Explore allows users of the XM-60 system to analyse stitched data to international standards for longer axes.

- The offset readings function in Explore allows the X, Y, Z deviations from the receiver to the point of interest to be entered into CARTO. Captured data is then recalculated to give the true errors at the source.

- The 3D error visualisation mode in Explore displays a scalable animation of the measured axis. This helps to understand the errors and the relationship between the 6 degrees of freedom.

Download CARTO software

Intuitive software that provides increased testing and reporting flexibility.

Expand capabilities with versatile software and fixturing

The XM-60 multi-axis calibrator provides a range of software and fixturing solutions. This enables measurement for an array of machine configurations, ensuring capability with a wide range of set-ups. Renishaw can provide Calibration product training from experienced engineers to ensure optimal product performance.

Rotary axis measurement

Capture and analyse rotary measurement data in CARTO software with the XR20 rotary axis calibrator. The CARTO Off-axis rotary measurement mode provides a single source for off-axis measurement tests with the XM-60 multi-axis calibrator.

Precision alignment

Our single-axis horizontal stage is an accessory which enables precise alignment in applications without an axis perpendicular to the travel. This is particularly useful for stage and printer applications.

Magnetic mounting

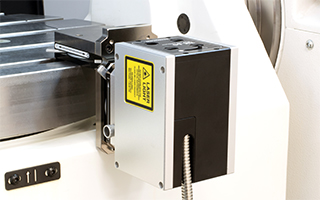

The integral switchable magnetic base on the XM-60 launch unit allows for quick attachment to the machine.

Fixturing kit

The fixturing kit extends the options for mounting the XM-60 launch unit and receiver into the working volume of a machine tool.

90 degree bracket

The 90 degree bracket helps to switch the orientation of the XM-60 launch unit with ease and can be used to mount the unit off the edge of the machine bed.

Clamp block mount

The XM-60 receiver can be easily attached to a machine using a clamp block and pillar method. For custom fixturing applications, the clamp block can be removed to utilise the tapped holes directly.

XM60 and XM-600 kit accessories

Browse our range of mounting accessories and replacement parts.

XM-600 enables faster and easier CMM error mapping

The XM-600 multi-axis calibrator has been designed with additional functionality allowing it to communicate directly with Renishaw's UCC controllers. Using technology developed for the XM-60 multi-axis calibrator, the XM-600 simultaneously measures all six degrees of freedom within a single measurement. This provides the ability to easily create an accurate error map for each linear axis of your CMM.

XM-600 is fully compatible with CARTO software, making it the ideal calibration solution for any manufacturing facility that utilises both machine tools and CMMs.

Using XM-600 we have noticed a considerable increase in efficiency for error mapping. The measurement and error mapping procedure has become very convenient, reducing the total working time by half for UCC CMMs, where it would typically take one day.

DUKIN, South Korea

Traceable accuracy

The performance of each XM-60 and XM-600 multi-axis calibrator is traceable to international standards.

Every system is supplied with a certificate of conformity that is unique and identified by the serial number of the components. This certificate provides information about the published specification that the system has been tested against and certified to meet. It ensure that each system will deliver the specified accuracy consistently during operation.

Engineered by Renishaw

Renishaw laser measurement systems are manufactured to provide high performance and operation. The aluminium substructure provides lightweight yet strong construction, designed to give the smallest package to fit onto the machine.

The laser uses technology developed and used in the RLE laser encoder system which has been produced for over 10 years, and can be found in the most demanding applications in the semiconductor industry. This gives total confidence in the reliability and accuracy that both the XM-60 and XM-600 multi-axis calibrator have to offer.

Discover our range of machine calibration and optimisation products designed to improve the performance of precision motion systems.

FAQs

What is six degrees of freedom (6DoF)?

There are six different types of errors in the linear motion. These are:

- linear

- horizontal straightness

- vertical straightness

- pitch

- yaw

- roll

Collectively these are the six degrees of freedom (6DoF).

What is the recommended recalibration schedule?

The recommended recalibration period for the XM-60 and XM-600 multi-axis calibrator when used in a 'normal' environment is two years. To find out more, visit out calibration service, repair and recalibration web page.