Calibration explained

Find out how calibration products work and how they can help to improve your processes.

Calibration is the foundation of process control

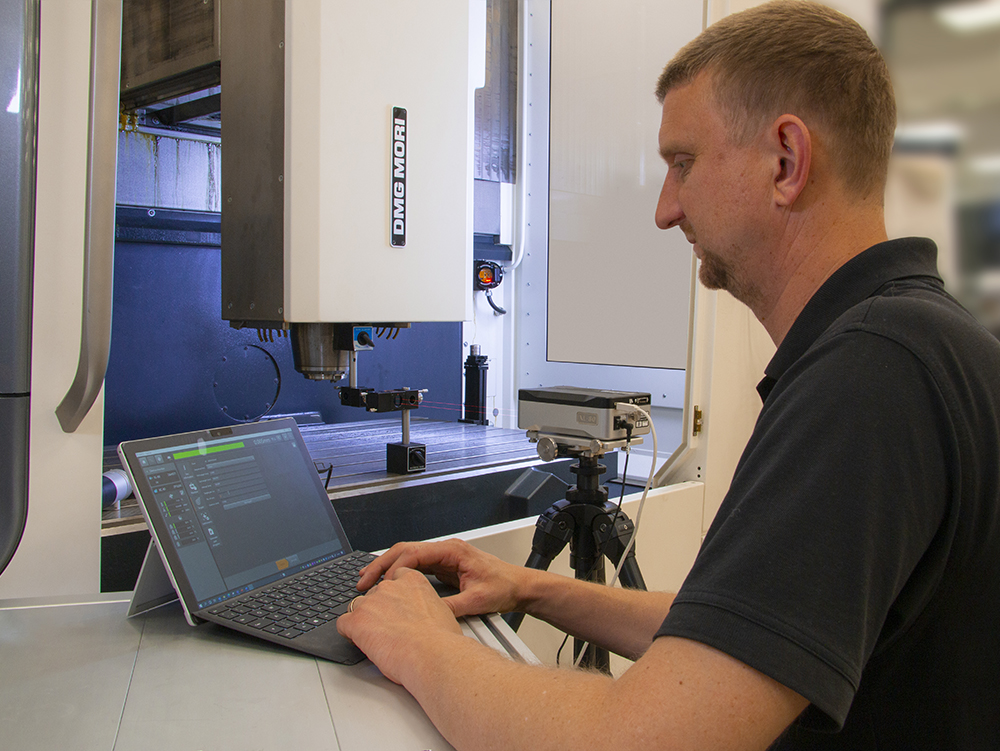

The modern industry has to meet ever tighter tolerances, customer schedules, and the requirements of international quality standards. Together with the pressure to reduce costs, the performance of equipment has never been more important.

Renishaw's range of machine calibration and optimisation products allow testing and diagnosis of machines during machine build, manufacture and commissioning to maintain higher accuracy of machines and minimise downtime.

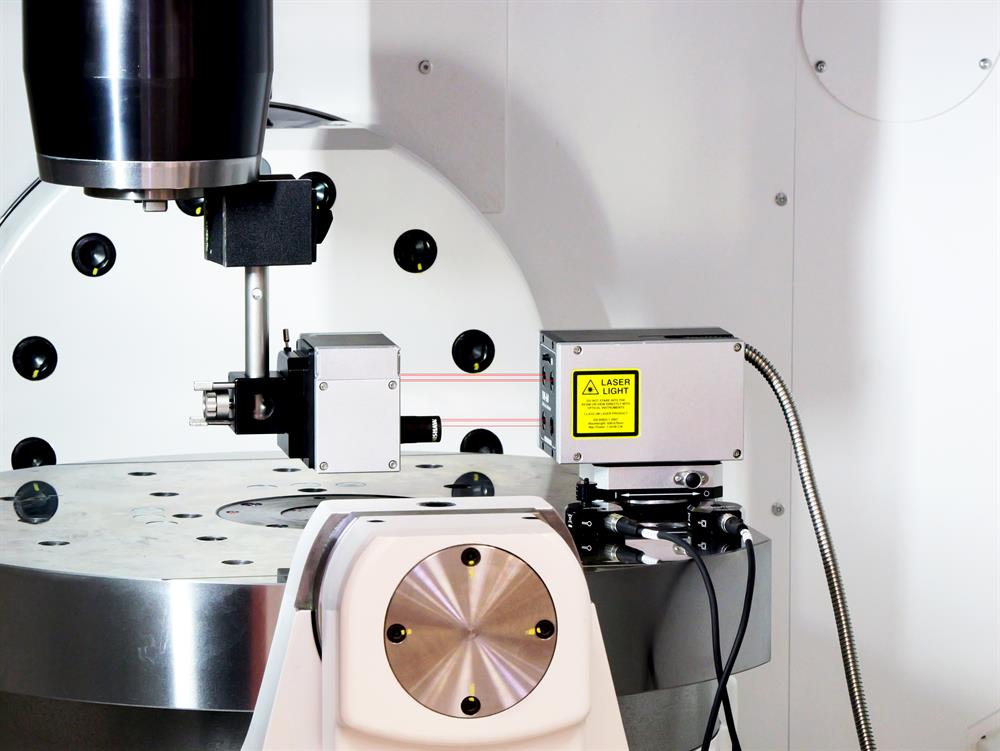

Interferometry explained

Laser interferometry is a well established method for measuring distances with great accuracy. Understand the basics of laser interferometry and how it can provide the most accurate and repeatable method of calibration.

Ballbar testing explained

The popularity of ballbar testing has been built on the basic simplicity of the test, quickness of use and the large amount of quantitative data generated. Find out about QC20 ballbar test set-up, data capture and analysis.

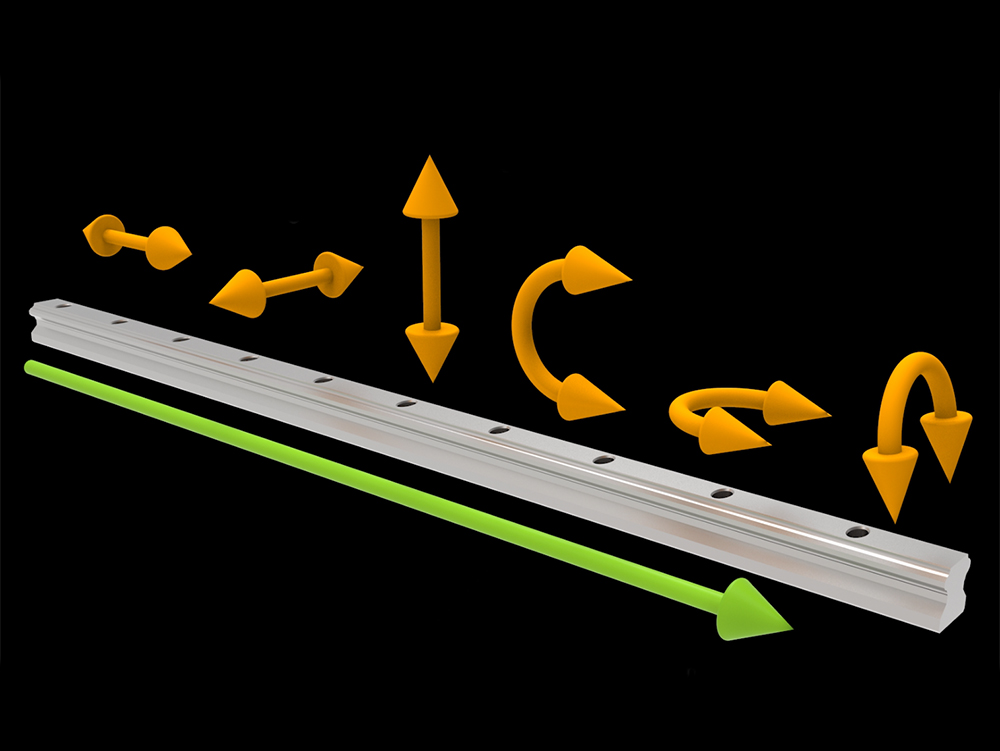

Six degrees of freedom explained

The XM-60 multi-axis calibrator enables users to simultaneously and directly measure all six errors for any orientation of motion.

Watch the explanation video to find out more about the different types of errors in a linear motion path.

Case studies

Explore how our laser calibration and ballbar technology has optimised performance across various industries.

Read in-depth insights into how calibration solutions have benefitted our customers.

Discover more about our range of calibration solutions for improved machine performance.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.