Creating “the world’s most beautiful bicycle” with additive manufacturing

Background

Global engineering company, Renishaw, has collaborated with J.Laverack Bicycles on the development of a luxury bespoke bike. Together, the companies have developed bespoke titanium lugs and components which pair to corresponding carbon fibre parts to create a first-of-its-kind road bike, the J.Laverack Aston Martin .1R. Described as the world's most bespoke, most advanced and most meticulously engineered road bike, it features titanium components made on Renishaw's RenAM 500Q metal additive manufacturing (AM) system.

J.Laverack is a UK-based designer and manufacturer of titanium bikes. Founded from a love of cycling, the team is passionate about how its bikes look, feel and perform.

“Our relationship with Aston Martin started when a member of the design team became a customer of ours,” said David Clow, Co-Founder of J.Laverack. “Because he used the bike to commute, it caught the eye of other Aston Martin team members and planted the seed for a collaboration between the two companies, and we set out to design a high-end, luxury bespoke bike together.”

Challenge

In a luxury bespoke bike, aesthetics are highly important. The aim was to make a visually ‘boltless' bicycle from a combination of titanium lugs and carbon fibre tubes, where nearly every element can be tailored to the exact measurements of the rider, from made-to-measure handlebars to unique frame sizes. This defies traditional bike design, allowing for components to be adjusted for different rider shapes, sizes and physical attributes.

“We started this project from a blank sheet of paper,” said Oliver Laverack, Co-Founder of J.Laverack. “We wanted to totally rethink bike design to make the most bespoke, beautiful and technologically advanced bike possible. It would be made to measure — to the millimetre — as a series of perfect one-offs.”

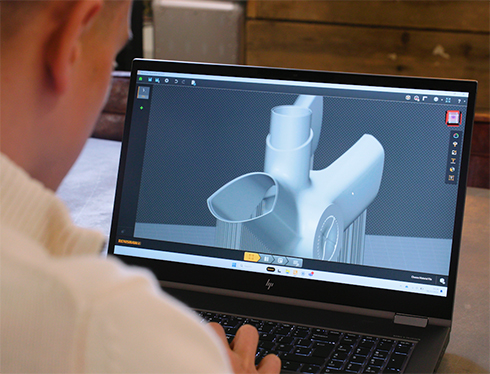

“During the development of the bike, we realised that 3D printing would enable us to make high-performance, geometrically optimised one-off parts,” continued Laverack. “AM requires no tooling and is perfectly suited to low volume, customised applications. However, AM is a relatively new technology and we had limited experience with it. We were looking for a development partner that we could have a strong relationship with, who could support and guide us with designing and manufacturing the AM components throughout the project.”

Solution

J.Laverack reached out to Renishaw for support in manufacturing the titanium lugs, brackets, fork dropouts, headtube, rear dropouts, seat tube lug and X-wing. Renishaw is a UK-based manufacturer of metal additive manufacturing systems, which are assembled at its Miskin facility in South Wales.

“Working with Renishaw on the additive manufacturing was a no brainer,” emphasised Clow. “Not only is it a world-renowned British engineering company, we were impressed by its work on the British Cycling Olympic track bikes.”

“We assessed the best way to lay out the individual parts on the build plate, determined the best angle to orientate them and designed a support strategy,” said Joe McMurtry, Mechanical Engineer at Renishaw.

“Because every AM part is different, so too is the approach, and we had to adapt accordingly to achieve the highest quality components. When making the top head tube, we decided to build the part on the plate without supports, adding extra stock to be machined off later to ensure there was no possibility for error when removing the part from the build plate,” continued McMurtry.

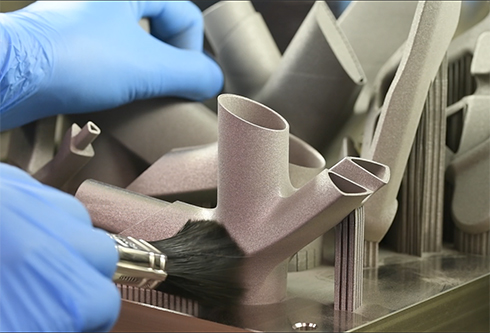

Renishaw engineers built the parts at an angle which eliminated overhangs and allowed them to create a geometry that didn't require internal supports. Metal additive manufacturing provided the design freedom needed to make complex geometries that would not have been possible using traditional subtractive methods, while enabling the lightweighting of components. This included internal lattice structures to reduce weight, an important factor with bike design and manufacture.

Once the design and support strategy was optimised, Renishaw began to print the components in aerospace-grade 6AI/4V titanium in 30 micron layers, then heat treated and post-processed them so they can be sent for Finite Element Analysis (FEA). The parts are produced on Renishaw's flagship RenAM 500Q system, which features an industry leading gas flow system, precision dynamic control and software for connected digital workflows.

For performance, keeping the weight of the bike as low as possible is important. Using AM, as opposed to more traditional frame-building approaches, meant we could remove materials from certain areas of the frame where it is not needed, helping to reduce weight from the bike. As a result, the J.Laverack Aston Martin .1R starts from just 7.5 kg.

David Clow

Co-Founder of J.Laverack

Results

The .1R is the world's first ‘boltless' bicycle, with no visible bolts, screws or attachments at the headset, seat clamp, calipers or bottle cage. Brake hoses are concealed within the handlebars which is a complex part that uses the same design and manufacturing technique applied to the front splitter of a Formula One car. Each bike takes over 1,000 hours to create, including over 500 hours of CNC machine time. Every detail is meticulously engineered and designed to meet the specific needs of each individual.

The titanium lugs have an exceptional strength-to-weight ratio due to the internal lattice structures, which enhance stiffness and torsional stability.

“This bespoke titanium and carbon bike is a great example of collaboration between British companies that are committed to innovation,” said Chay Allen, Customer Applications Manager at Renishaw.

“I think we've made the most beautifully designed and engineered bike in the world,” said Oliver Laverack. “It is sleek, stiff, fast, and we have the ability to make them totally bespoke to the individual. It really is a masterpiece in British engineering, and shows what a true collaboration can achieve. We were impressed with Renishaw's knowledge and support throughout the project,” continued Laverack. “The team was able to make recommendations and changes to ensure we ended up with the best possible parts. Now we've seen the power of what AM can achieve, we'd like plan to take the AM learnings and roll it out into our core product range.”