XR20 rotary axis calibrator

Rotary axis positioning is critical to machine accuracy. Renishaw's XR20 rotary axis calibrator provides rapid calibration of rotary axes, to ±1 arc second accuracy.

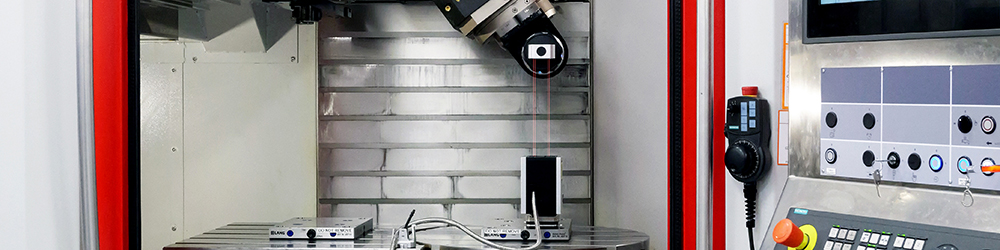

Any 5-axis machine tool or mill-turn machine can have accuracy errors. These include angular positioning errors and alignment of the axes, both of which can have a detrimental effect on parts being machined.

Early error detection with a rotary axis calibrator ensures optimum machine performance is achieved. Renishaw's XR20 rotary axis calibrator is a highly accurate solution alongside the XL-80 and XM-60 laser systems.

The XR20 rotary axis calibrators wireless operation and modular mounting systems ensure suitability for a wide range of machines. The calibration data can be used to check for errors, establish performance trends and efficiently schedule maintenance and repairs.

What is a rotary axis calibrator?

The XR20 rotary axis calibrator consists of an integrated angular retroreflector mounted on a precision servo-controlled axis. The angular position of the axis, and the optics relative to the main body housing, is controlled by a very high accuracy encoder system with the scale directly machined on the main bearing.

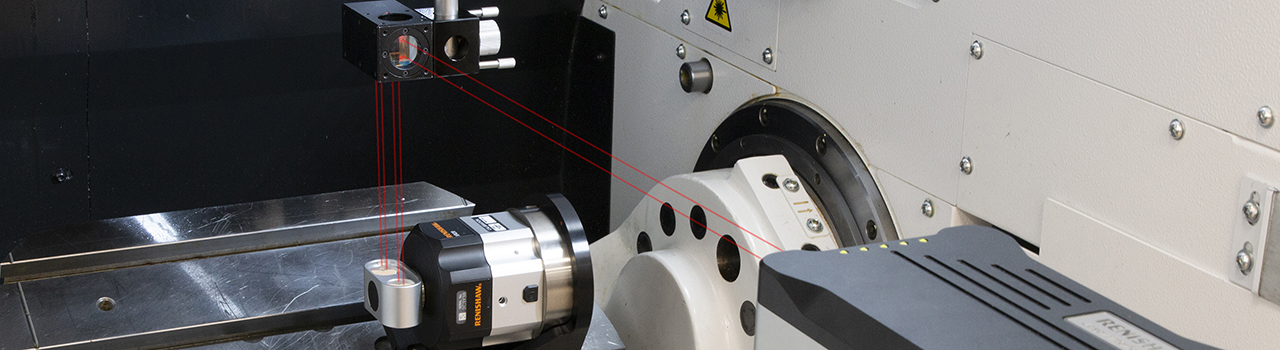

The XR20 rotary axis calibrator works in conjunction with our XM-60 multi-axis calibrator and XL-80 laser system to provide highly accurate, repeatable rotary axis calibration for stages, jigs and machine tools.

Key benefits

Flexible fit

Designed for easy fitment to a wide variety of rotary tables, lathes and other rotary axes.

Intuitive design

Built-in alignment targets help to effectively minimise measurement errors during set-up.

Auto calibration

Angular alignment errors compensated for using pre-measurement calibration cycle.

High accuracy

Performance assured with ±1 arc second verification of rotary axes in any orientation.

With the features of the XR20 (easy and flexible setup due to its size and weight, wireless operation and user-friendly software), we have reduced our test setup time by 40% and test run time by 20%.

An added benefit is that wireless testing has allowed safer testing making supervision a non issue. As a result we do not disrupt shop floor activity, a great attraction to our operations and quality procedures.

Hurco (Taiwan)

Rotary axis calibration with the CARTO software suite

CARTO software is used for capturing data, analysis and rotary measurement using the XL-80 laser or XM-60 multi-axis calibrator. CARTO is made up of three applications:

- Capture to collect laser measurement data.

- Explore for powerful analysis to international standards.

- Compensate for quick and easy error correction.

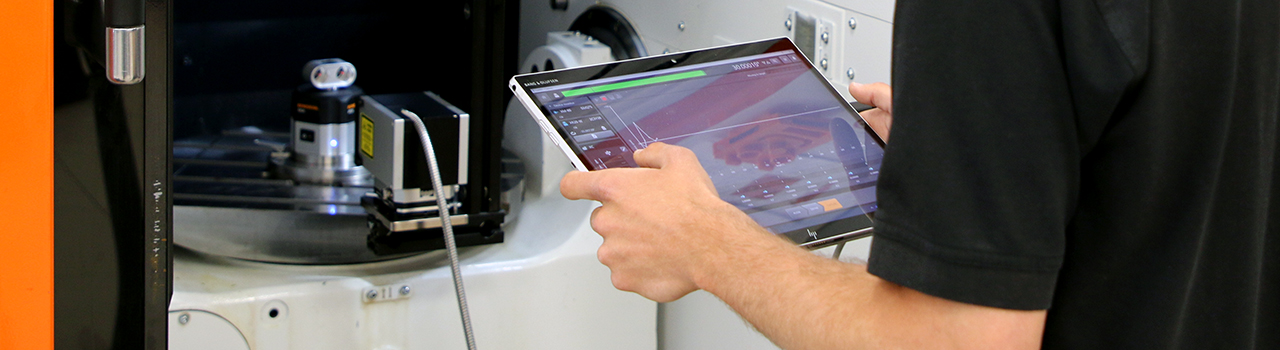

The CARTO user interface provides a simple process flow that enables users to easily capture and manage their data. Featuring the latest Bluetooth Low Energy (BLE) technology, the XR20 rotary axis calibrator rapidly forms a robust wireless connection with the PC and provides superior power efficiency, plus a substantially longer battery life when in use.

Built in functions such as automatic sign detection' and first target pre-set' give confidence that collected data is right first time. This approach allows for greater productivity whilst using Renishaw's machine calibration and optimisation products.

Off-axis rotary measurement

Off-axis rotary measurement mode in the CARTO software provides a single source for testing off-axis measurement using the XR20 rotary axis calibrator with the XL-80 laser system or XM-60 multi-axis calibrator. This streamlines the measurement of rotary positioning accuracy for 5-axis machine tools, where the XR20 rotary axis calibrator cannot always be mounted on the centre of rotation.

The software outputs part programs for synchronised movement of rotary and linear axes to maintain beam alignment throughout the test.

XR20 90° bracket

The mounting of the XR20 rotary axis calibrator relative to the axis under test is vital for accurate measurement. Renishaw has designed the XR20 90° bracket to remove complexity of manufacture for the user. This accessory is manufactured to extremely fine tolerances required to achieve accuracy of testing.

Flexible fixturing options are provided by removable magnetic feet and a variety of through holes for direct bolt attachment. The bracket is useful for meeting the mounting requirements of 'off-axis' rotary measurements and resolving 'on-axis' mounting difficulties on trunion type machines.

For OEM users, full specifications for custom mounting manufacture can be found in the XR20 user guide.

Flexible mounting options

Mounting the XR20 rotary axis calibrator to rotary axes is simplified using a range of modular mounts to suit different applications.

Standard mounting

Centring on the axis is typically very simple, using the markings around the circumference of the mounting ring and the centration aid.

Flexible mounting

A mounting ring adaptor plate enables the XR20 rotary axis calibrator to be fitted to rotary tables with unsuitable centre recesses. It can also be used to secure the XR20 rotary axis calibrator to the chuck (lathe) adaptor and custom mounts.

Renishaw can provide calibration product training from experienced engineers to ensure optimal product performance. Talk to our sales team discuss your application and training requirements.

FAQs

Does the XR20 rotary axis calibrator need to have a periodic recalibration?

Yes, the recommended time between recalibrations is 36 months for items when used in a 'normal' environment. More frequent calibration is advised for units used in extreme environmental conditions, or where damage is suspected. The requirement for your quality assurance programme or national/local regulations may also dictate more frequent recalibrations.

During storage, transportation and in use, the XR20 rotary axis calibrator should not be subjected to excessive shock, vibration or extremes of temperature, pressure or moisture, as any of these factor could invalidate calibration.

To find out more, visit our calibration service, repair and recalibration web page.

Does the XR20 rotary axis calibrator maintain its accuracy in all orientations?

Yes. The specified accuracy applies to all possible orientations.

Additional resources

-

Brochure: XR20 rotary axis calibrator

Brochure: XR20 rotary axis calibrator

-

Application note: XR20 rotary axis calibrator spares list

Application note: XR20 rotary axis calibrator spares list

-

Application note: Error budget and uncertainty calculations: XR20-W rotary axis calibrator

Application note: Error budget and uncertainty calculations: XR20-W rotary axis calibrator

-

Data sheet: Traceability chart: Rotary axis calibrator

Data sheet: Traceability chart: Rotary axis calibrator

-

Product note: Compliance of XR20 rotary axis calibrator with radio device regulations

Product note: Compliance of XR20 rotary axis calibrator with radio device regulations