Navigation

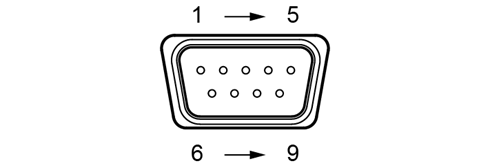

E-STOP (9W 'D' plug)

The E-STOP connector is provided to allow connection of external emergency stop and reset switches into the SPA3. The machine manufacturer or product installer must perform a risk assessment (refer to BS EN ISO13849-1:2015 (or current version) para. 5.2.2.) to determine the requirements for emergency stopping and emergency switching off.

| Pin number | Function |

|---|---|

1 | E-STOP A1 |

2 | Not connected |

3 | 0 V |

4 | E-STOP B1 |

5 | E-STOP RESET A |

6 | E-STOP A2 |

7 | E-STOP B2 |

8 | Not connected |

9 | E-STOP RESET B |

NOTE: The emergency stop function of the SPA3 can be used as part of a Performance Level B system as per BS EN ISO13849-1:2015 (or current version). To meet a higher performance level an external safety system must be fitted.

E-STOP electrical characteristics

A manual reset button (refer to BS EN ISO13849-1:2015 (or current version) para. 5.2.2.) shall be included in the emergency stop system when required by the user's risk assessment. A reset switch may be needed when there is limited visibility of the danger zone from the machine's control position.

Reset switches must be located with full visibility of the danger zone and shall be sited outside the danger zone.

NOTE: If no additional emergency stop devices are to be added to the system then a bypass plug is required for the SPA3 emergency stop system to function.

All connections to the bypass plug shall be fitted by an electrically competent person and all wires are to be sleeved.

Any emergency stop device added to the E‐STOP chain must have an electrical rating of at least 24 V 300 mA and meet the requirements of BS EN ISO 13850:2015 (or current version).

The emergency stop device shall have direct opening action with mechanical latching. The emergency stop devices shall comply with BS EN 60947-5-5:1998+A2:2017 (or current version).

CAUTION: It is strongly recommended that the CMM manufacturer or retrofitter includes a periodic test of the emergency stop (and associated reset switch, if fitted) in the maintenance instructions.

Dual SPA3 installations

Dual SPA3 installations use the same connection above, however the installation requires a special emergency stop link cable (Renishaw part number A-5623-0095). This is supplied in the 6-axis SPA3 kit.

This cable allows the emergency stop system to operate both SPA3 units. The cable ends of this cable are marked with their function. The SPA3 containing the MCU must have the cable end marked 'master' plugged into its external E-STOP connector, whilst the cable end marked 'slave' must be connected to the other SPA3.

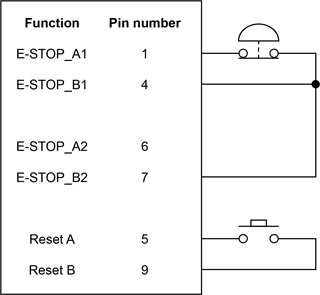

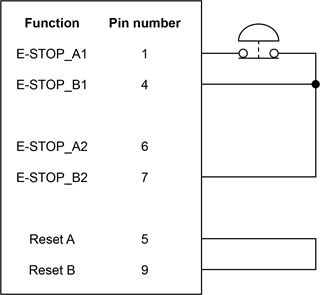

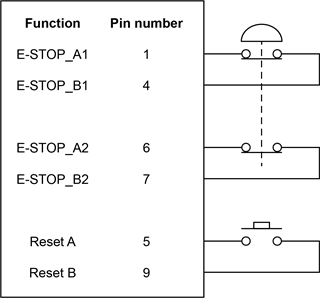

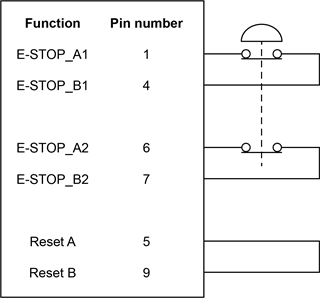

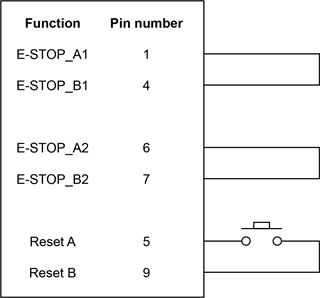

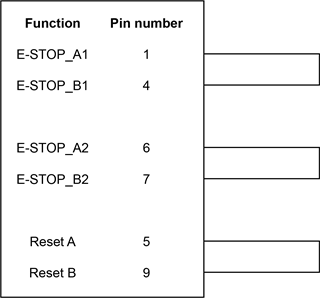

There are six methods of implementing the external E-STOP circuit:

| E-STOP with reset implementation | E-STOP without reset implementation |

Single pole E-STOP button:  | Single pole E-STOP button:  |

Dual pole E-STOP button:  | Dual pole E-STOP button:  |

Bypass plug:  | Bypass plug:  |