Standard-accuracy machine tool touch probes

Move from manual to automated workpiece setup and inspection. Explore our range of standard-accuracy machine tool touch probes for accurate and repeatable measurement.

Maximise machining time

Time spent manually setting and inspecting workpieces is valuable machining time wasted. With automated probing, you can speed up part set-up times and simplify in-process inspection.

Our standard-accuracy touch probes use a kinematic design, proven over five decades. The mechanism enables measurement repeatability of 1.00 µm 2σ, allowing you to set and inspect components accurately and reliably. Other benefits include:

- Reduced machine downtime.

- Automatic fixture, job alignment and rotary axis set-up.

- Manual setting errors eliminated.

- Reduced scrap.

- In-cycle part measurement with automatic offset correction.

Previously it could take 90 minutes to set a job that took over 4 hours of machining; that was unacceptable. Now we can do the same set-up in 10 minutes, immediately freeing up 80 minutes to cut more metal, which we make money on.

Sewtec Automation (UK)

Explore our portfolio and find the right standard-accuracy touch probe for your application

Recommended machine type | Unidirectional repeatability | Transmission type | Compatible interfaces* | Recommended stylus length | |

OMP40-2 | Small to medium machining centres and small multi-tasking machines | 1.00 µm 2σ | Optical | OMI-2, OMI-2T, OMI-2C, OSI with OMM-2 | Up to 150 mm |

OMP60 | All sizes of machining centres and small to medium multi-tasking machines | 1.00 µm 2σ | Optical | OMI-2, OMI-2T, OMI-2C , OSI with OMM-2 | Up to 150 mm |

RMP40, RMP60 | All sizes of multi-tasking machines, machining centres and gantry machines | 1.00 µm 2σ | Radio | RMI-Q or RMI-QE** | Up to 150 mm |

OLP40 | Turning centre | 1.00 µm 2σ | Optical | OMI-2, OMI-2T, OMI-2C, OSI with OMM-2 | Up to 150 mm |

RLP40 | Turning centre | 1.00 µm 2σ | Radio | RMI-Q or RMI-QE** | Up to 150 mm |

LP2 | Turning centre/grinding machine | 1.00 µm 2σ | Hard-wired | HSI or HSI-C | Up to 100 mm |

LP2H | Turning centre/grinding machine | 2.00 µm 2σ | Hard-wired | HSI or HSI-C | Up to 150 mm |

*All Renishaw machine tool probes require a compatible interface to operate.

** RMI-QE interface is only compatible with QE series probes.

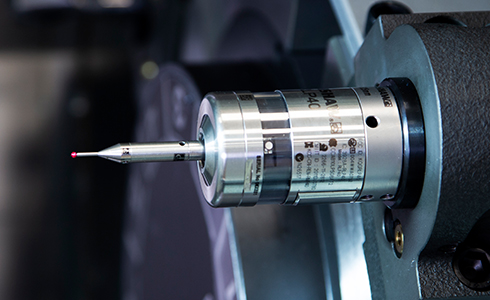

Optical transmission probes

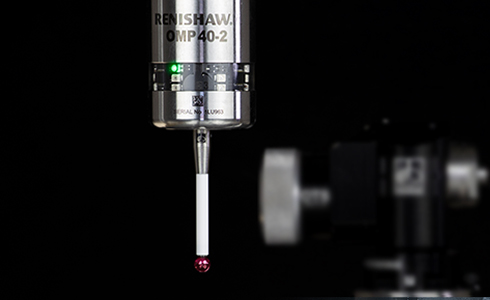

OMP40-2

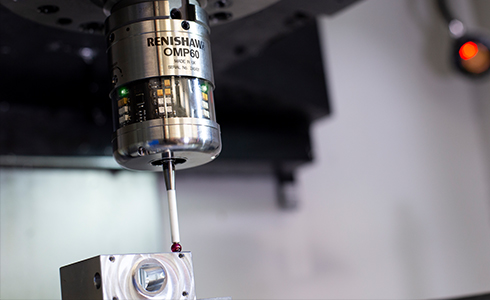

OMP60

The ultra-compact OMP40-2 (40 mm diameter) and compact OMP60 (63 mm diameter) touch-trigger probes with optical transmission provide a flexible probing solution. The OMP40 is suitable for small to medium machining centres whilst the larger OMP60 is suitable for all sizes of machining centres and small to medium multi-tasking machines. Both probes are ideal for workpiece set-up and inspection.

- Proven kinematic design.

- Exceptional resistance to light interference with modulated transmission.

- 360° transmission envelope.

- Various activation options and adjustable trigger force (OMP60 only).

- 1.00 µm 2σ repeatability.

Radio transmission probes

RMP40

RMP60

Offering superior communication capability, the ultra-compact RMP40 (40 mm diameter) and compact RMP60 (63 mm diameter) probes are suited for operation on machines of all sizes. The traditional kinematic resistive mechanism combined with unique radio transmission technology make them ideal for modern machine shops where line-of-sight between probe and interface is not always possible.

- Proven kinematic design with secure frequency hopping spread spectrum (FHSS) radio transmission.

- Globally recognised 2.4 GHz waveband compliant with radio regulations in all major markets.

- Various activation options.

- Adjustable trigger force (RMP60 only).

- 1.00 µm 2σ repeatability.

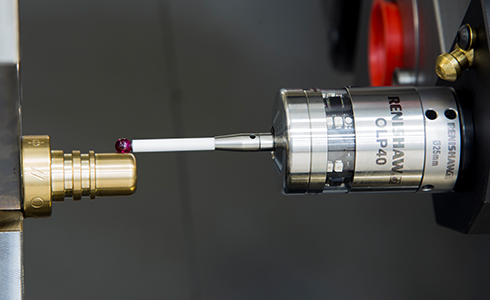

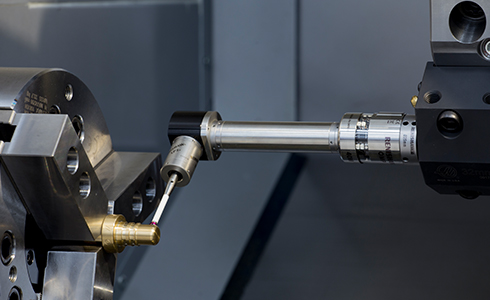

Lathe probes

OLP40

RLP40

Designed specifically for workpiece set-up and inspection on lathes and grinding machines, our robust lathe probes provide outstanding metrology performance. Both probes offer an ultra-compact design, measuring just 40 mm in diameter.

- Proven kinematic design.

- Exceptional resistance to light interference (OLP40 optical transmission probe).

- Secure frequency hopping spread spectrum (FHSS) (RLP40 radio transmission probe).

- Design enhancements for operation in harsh machining environments.

- 1.00 µm 2σ repeatability.

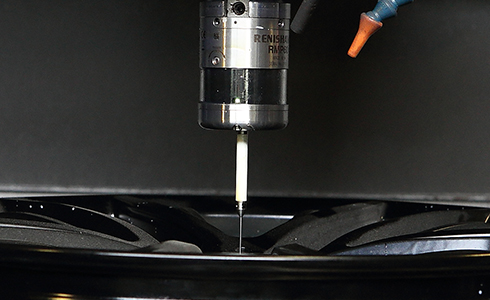

Modular probes

LP2 and LP2H

For workpiece inspection and job set-up on all sizes of lathes, machining centres and CNC grinders. LP2 features a stylus spring force which is adjustable for different applications. LP2H has a higher, fixed spring force, allowing the use of longer styli and providing greater resistance to machine vibration. Double diaphragm (DD) variants for both probes are available for enhanced sealing when used in harsh environments with particle-laden coolant.

- Proven kinematic design.

- Interference-resistant, hard-wired communication.

- Miniature design (25 mm in diameter)

- Robust probe design for operation in harsh machining environments.

- 1.00 µm 2σ repeatability (LP2) / 2.00 µm 2σ repeatability (LP2H).

All probe variants are suitable for use with the modular OMP40M and OMP60M optical transmission systems and RMP40M and RMP60M radio transmission systems. They can also be mounted directly to a machine and hard-wired for component inspection in grinding applications.

OMP40M and OMP60M

RMP40M and RMP60M

Our modular transmission systems (OMP40M / OMP60M and RMP40M / RMP60M) enable a probe to access features for inspection or part setting which might be inaccessible with a standard unit. We offer a comprehensive range of adaptors, extensions and stylus configurations to tackle even the most demanding probing applications.

Remove manual steps in machine tool probe calibration

Spindle probes for CNC machine tools rely on accurate calibration to achieve a high level of repeatability. Manual calibration, whilst common, may introduce variability, affecting the accuracy of subsequent measurements.

ACS-1 (Advanced Calibration Sphere) removes manual calibration steps, helping you to achieve maximum measurement accuracy on your machine tools.

Next steps

To request more information or buy, submit a contact form to speak with your local office.

Contact usDownloads

Brochures

-

Brochure: OMP40-2 optical transmission probe

Brochure: OMP40-2 optical transmission probe

-

Brochure: OMP60 optical transmission probe

Brochure: OMP60 optical transmission probe

-

Brochure: RMP40 compact radio touch probe

Brochure: RMP40 compact radio touch probe

-

Brochure: RMP60 high accuracy touch probe

Brochure: RMP60 high accuracy touch probe

-

Brochure: OLP40 lathe touch probe

Brochure: OLP40 lathe touch probe

-

Brochure: RLP40 radio transmission lathe probe

Brochure: RLP40 radio transmission lathe probe

-

Brochure: Next generation probing systems for machine tools - QE series

Brochure: Next generation probing systems for machine tools - QE series

Data sheets

-

Data sheet: OMP40-2

Data sheet: OMP40-2

-

Data sheet: OMP60 optical machine probe

Data sheet: OMP60 optical machine probe

-

Data sheet: RMP40 (QE) radio machine probe

Data sheet: RMP40 (QE) radio machine probe

-

Data sheet: RMP40 radio machine probe

Data sheet: RMP40 radio machine probe

-

Data sheet: RMP60 (QE) radio machine probe

Data sheet: RMP60 (QE) radio machine probe

-

Data sheet: RMP60 radio machine probe

Data sheet: RMP60 radio machine probe

-

Data sheet: OLP40 optical lathe probe

Data sheet: OLP40 optical lathe probe

-

Data sheet: RLP40 (QE) radio lathe probe

Data sheet: RLP40 (QE) radio lathe probe

-

Data sheet: RLP40 radio lathe probe

Data sheet: RLP40 radio lathe probe

-

Data sheet: LP2 modular probe system for tool setting and workpiece inspection

Data sheet: LP2 modular probe system for tool setting and workpiece inspection

-

Data sheet: Optical modular probes

Data sheet: Optical modular probes

-

Data sheet: OMI-2 optical machine interface

Data sheet: OMI-2 optical machine interface

-

Data sheet: OMI-2T

Data sheet: OMI-2T

-

Data sheet: OMI-2C optical machine interface

Data sheet: OMI-2C optical machine interface

-

Data sheet: OSI with OMM-2 multiple optical probe interface system

Data sheet: OSI with OMM-2 multiple optical probe interface system

-

Data sheet: RMI-Q radio machine interface

Data sheet: RMI-Q radio machine interface

-

Data sheet: RMI-QE radio machine interface

Data sheet: RMI-QE radio machine interface

-

Data sheet: HSI high speed interface

Data sheet: HSI high speed interface

-

Data sheet: HSI-C

Data sheet: HSI-C

Software that makes probing simple

Explore our range of probing software and machine tool apps that allows you to quickly and intuitively program measurement cycles.

Inspection probe software

Looking for support?

Contact us or visit our technical support library for installation manuals, user guides and compliance information.