Widening the scope for machine tool designers with the FORTiS™ enclosed encoder

The FORTiS enclosed encoder has been designed to cater for the needs of machine tool OEMs, end-users and service providers. An application note written specifically for the machine tool end-user and service markets can be found here.

When considering machine design, direct feedback can deliver superior dynamic position control

Semi-closed loop systems, where the pitch dimension of a ballscrew effectively forms part of the measuring standard, are commonplace in a broad range of machine tool designs. Positioning errors due to thermal effects on ballscrews and other components are well known and can be mitigated to a large degree through various temperature control measures. For positional accuracy and repeatability, machines designed with these features can help the semi-closed loop system perform significantly better than those without them.

It is, however, widely accepted that closed loop positioning systems, where linear encoders provide direct feedback of a machine's linear axes, typically deliver the ultimate in dynamic position measurement. In other words, building accuracy in enables a good machine to perform to even higher levels.

As demand for ever tighter tolerances stimulates interest in higher machine specifications, machine design criteria such as the choice of semi-closed, or fully closed loop feedback is surely a key consideration.

Whether considered as a foundation level within the scope of a process control framework, or simply as a high accuracy machine specification, adoption of closed loop positioning systems continues to increase. The introduction of the FORTiS™ enclosed linear encoder range now enables a wider analysis of this proposition, either as a machine builder's standard specification, or a customer-selectable high-performance option.

Why choose an enclosed linear encoder from Renishaw?

For decades machine tool builders and industrial users have recognised the Renishaw brand for calibration, probing, tool setting, gauging and coordinate measurement.

Renishaw has also developed a large open encoder product range based on modern optical technologies. These industry-proven encoders are used successfully for precision metrology and motion control applications across a broad range of applications and industries.

Renishaw's years of experience in machine tool applications, metrology, position measurement and motion control were applied to the development of a new, innovative enclosed linear encoder that offers distinct advantages over present conventional enclosed optical encoders.

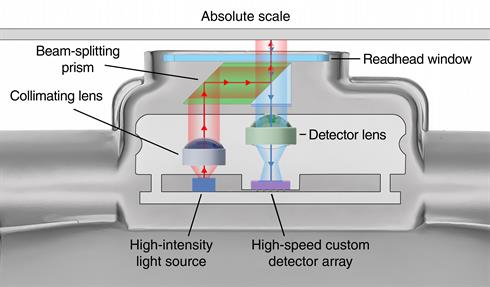

Figure 1. The single track, fine pitch (30 μm) optical scale is read by a miniature ultra-high speed digital camera housed in a sealed readhead, offering greater contamination resistance.

Enclosed linear encoders for use in harsh environments have been available for many years and follow a common set of design features, such as mounting hole arrangements, enclosure sizes, and internal mechanisms to provide guidance for the readhead over the scale. The FORTiS encoder series uses conventional form factors and bolt hole arrangements but benefits from an innovative non-contact mechanical design.

Figure 2. FORTiS encoder hysteresis errors in the positive (forward) and negative (backward) directions after five experimental runs.

How is the FORTiS encoder different?

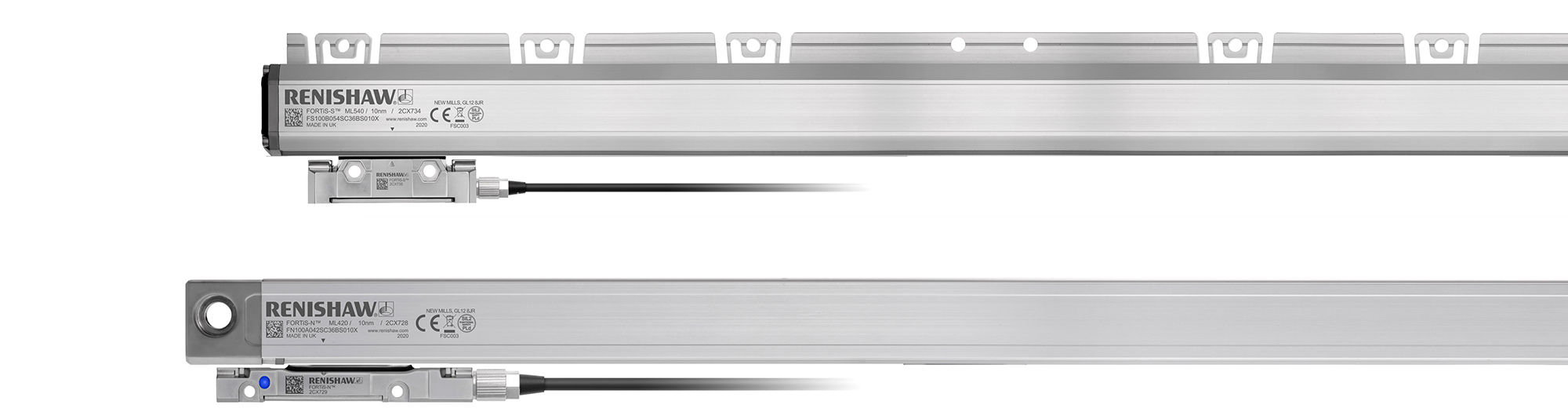

FORTiS encoders are form and fit compatible with other conventional designs of enclosed optical encoder. Measuring lengths are also matched to existing machine designs, with the FORTiS-S™ (standard) model ranging from 140 mm to 4,240 mm and the space saving FORTiS-N™ (narrow) models from 70 mm to 2,040 mm.

These encoders are available with the most popular controller communication protocols and with resolution options from 50 nm to 0.5 nm. Multi-readhead encoder systems and Functional Safety variants are also available.

However, the internal structure of the FORTiS encoder system includes a range of innovative new features that are distinct from conventional enclosed encoder designs.

Instead of glass, the scale is made of tough stainless steel which is more robust and has a coefficient of thermal expansion (CTE) of 10.1 ±0.2 μm/m/°C, which is similar to the CTE of the base materials used in most machines. This matching of CTE values can help reduce errors due to thermal effects whilst increasing measurement certainty. Low positional noise (jitter) of below 10 nm RMS and low Sub-Divisional Error (SDE, the error within a scale period) of just ±40 nm enables encoder feedback of superior fidelity, to ensure smoother velocity control and rock-solid positional stability.

The single track, fine pitch (30 μm) optical scale is read by a miniature ultra-high speed digital camera housed in a sealed readhead, offering greater contamination resistance, as shown in Figure 1.

The readhead moves over the scale without any contact, delivering significant advantages over conventional encoder designs that include contact guidance mechanisms with delicate roller bearings and springs.

Having no internal moving or sliding parts eliminates wear, minimises risk of scale breakage, and improves reliability, to deliver a longer system lifespan. Furthermore, hysteresis and backlash errors (as shown in Figure 2) associated with mechanical contact designs are reduced, improving workpiece surface finish and form.

A breakthrough in readhead design

A key focus for Renishaw's engineers has been the effect of vibration on a linear enclosed encoder. Conventional contact encoders are known to be susceptible to vibration effects under certain conditions such as the machining of particularly tough materials, intermittent cutting, and gradual machine wear.

The non-contact readheads of both the FORTiS-S and FORTiS-N models benefit from the application of tuned mass damping technology, enabling class leading vibration resistance.

Tested beyond 30 g for extended time periods, even at the encoder's resonant frequency, both FORTiS encoder models achieve the same robust measurement performance and can endure the same harsh conditions. The sealed readhead bodies, shown in Figure 3, also protect the encoder from immersion in the rare event of a flooded encoder housing, enabling in-field cleaning for a faster recovery from machine down' situations.

Figure 3. Vertical sections through FORTiS-S and FORTiS-N enclosures showing non-contact readhead orientations.

Figure 3. Vertical sections through FORTiS-S and FORTiS-N enclosures showing non-contact readhead orientations.

Figure 4. Side views of the FORTiS-S and FORTiS-N encoder.

Simpler and faster installation

Minimising the time and effort required to install an encoder in a machine is essential. Unlike traditional enclosed encoders, the installation process of the FORTiS encoder is not reliant upon dial gauges and peripheral diagnostic equipment.

Renishaw's patented set-up LED and carefully designed installation accessories provide an intuitive procedure that ensures a right-first-time installation, up to 90% faster than other typical contact encoder systems, even in space constrained locations.

A major advantage of the FORTiS design is that the set-up LED indicates signal strength, so a blue LED showing maximum signal strength also confirms correct alignment of the encoder's body and readhead whilst an axis is traversed.

This simple installation method allows linear encoders to be installed by an assembly operator, improving production flow through the factory, and freeing up highly skilled technicians for other tasks.

For enhanced functionality, installers can connect the Advanced Diagnostic Tool, ADTa-100, via a standard USB connector to a PC running Renishaw's ADT View software.

This provides a user-friendly graphical interface of advanced diagnostic information, including key encoder performance parameters such as signal strength along the axis length.

A permanent record of installation data can be saved, providing confidence to both machine tool builders and end users.

Figure 5. Samples of installation accessories (FORTiS-S featured).

Figure 5. Samples of installation accessories (FORTiS-S featured). Figure 6. ADT View software interface

Figure 6. ADT View software interfaceSaving energy and reducing operational costs

Accelerated life testing simulating five years under the harshest conditions, has enabled Renishaw to develop and refine the advanced DuraSeal™ lip seals. These offer excellent resistance to wear and machine tool lubricants, providing superior sealing and ingress protection up to IP64 when combined with air purge.

In addition to increasing machine uptime, this seal design reduces air leakage from the air purge system by up to 70 %, which results in lower operating costs, a reduced carbon footprint and longer filter life.

Lifetime wear tests on the DuraSeal lip seals were carried out with fine iron swarf and carbide grit deliberately added to their contact surfaces for maximum abrasion.

Even after 14 million cycles, the lip seals showed only minor wear and were fully functional, proving the encoder's suitability for long-life use in applications such as grinding, where the encoder will be exposed to extremely aggressive abrasives.

Through these design innovations the FORTiS enclosed linear encoder range offers key technical and commercial benefits in performance and operation to both machine tool builders and end user customers.

Figure 7. Comparison of purge air costs between the FORTiS encoder and a conventional enclosed encoder.