Precision styli for metrology

Renishaw offers a comprehensive range of precision styli for touch probes. Learn how the quality of styli and accessories play a vital role in industry measurement technology and how Renishaw can support you.

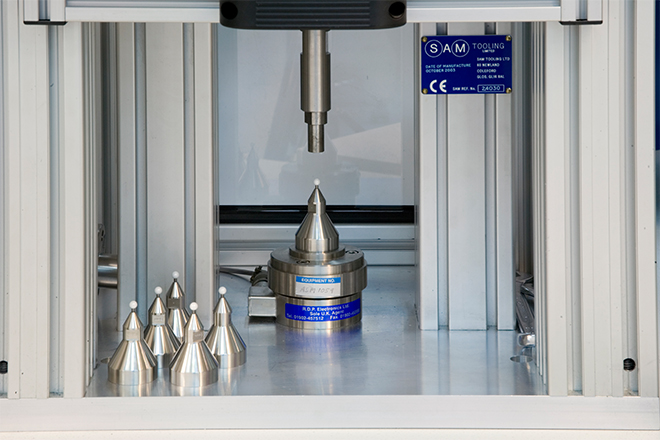

Renishaw precision styli

Styli for Renishaw's CMM, machine tool, scanning probes and Equator™ gauging systems.

Your partner in precision for 50 years

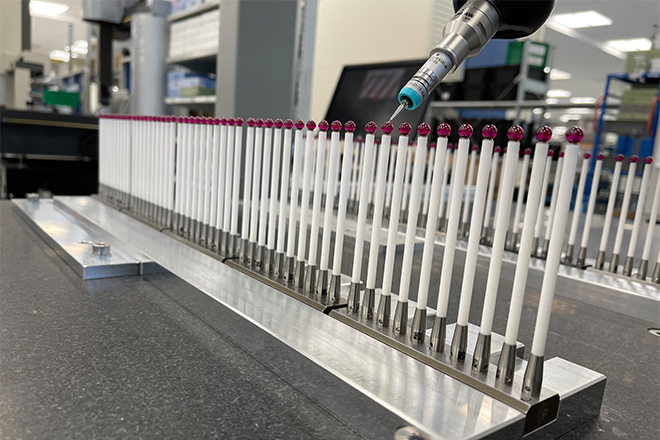

Precision styli are designed to complement Renishaw's probing systems, to ensure optimum performance. Our standard range comprises over 500 parts, with custom variants available on request. We also have an extensive and experienced applications network that can provide you with full technical support and guidance regarding styli design and their use within your unique application.

Renishaw supplies styli for a variety of applications, including providing compatibility with ZEISS and FARO® probes. To find out more about our styli range visit our Online store below.

Our comprehensive range of styli can be used on a variety of systems. These includes Renishaw's CMM, machine tool, scanning probes, and Equator™ gauging systems. Additionally, they can be used with sensors from other manufacturers.

Renishaw has developed OPTiMUM™ diamond styli to support the increasing need for high-speed scanning applications. Discover how diamond-coated spheres maintain their roundness and do not suffer material ‘build-up' or premature wear when scanning a part.

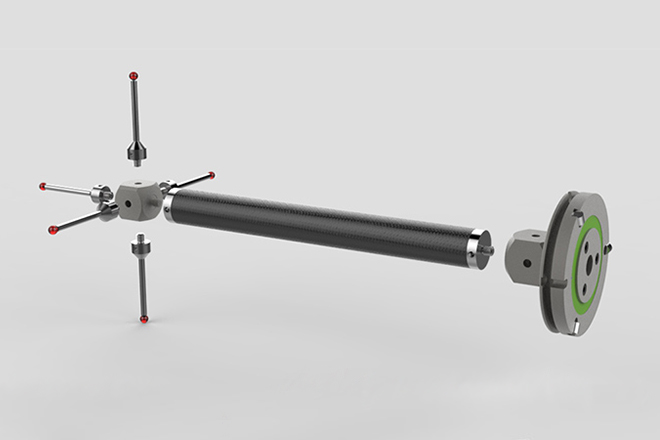

When our comprehensive standard product range does not provide the answer, custom styli can be developed by Renishaw's in-house design team. Let us design custom styli to suit your specific application requirement.

Metal additive manufacturing (AM) is a flexible and powerful technology that can be used to create components and parts which cannot be made using traditional manufacturing methods. Find out how AM styli provides more measurement options than ever before.

Your solutions partner for automotive manufacturing

Mass production of automotive components relies heavily on repeatable processes of inspections and quality checks during manufacturing.

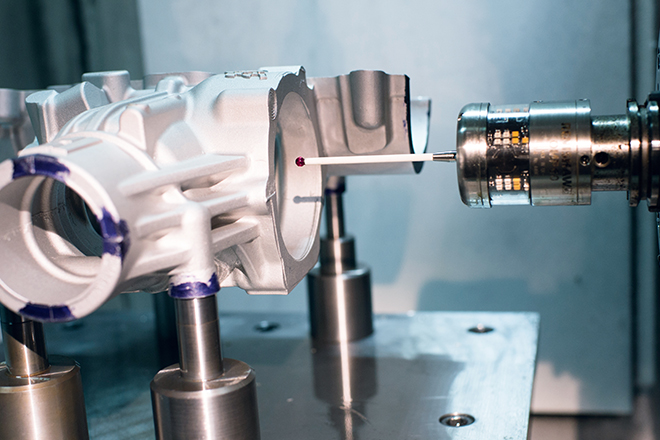

Although the styli of the inspection probes may seem like a small detail of the process, they are a crucial part of the measurement since they make contact with the component, allowing the probe mechanism to move and the generated signal to allow the measurement to be taken.

At Renishaw we take into account the small details, such as the proper use of the probes. When choosing a stylus, it is essential to consider the features and materials of the component to be measured. Additionally, it is important to consider the probing system in use. Stylus properties such as material, size, rigidity and sphericity can significantly influence measurement performance and system maintenance requirements.

Why become a Renishaw customer?

The quality of styli and accessories play a vital role in industrial measurement technologies. With our styli you can be assured of:

- A standard range of over 500 parts and over 15,000 custom variants.

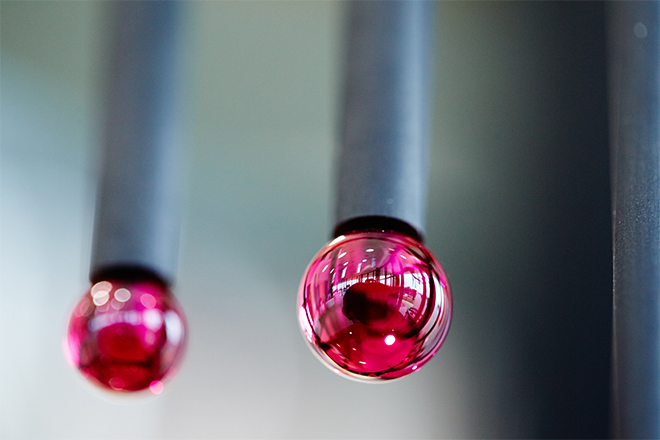

- Top precision balls. Grade 5 (0.13 microns sphericity) as standard, grade 3 (0.08 microns sphericity) on request.

- A wide range of material combinations.

- An extensive and experienced applications network that can provide you with full technical support and guidance regarding styli design and their use within your unique application. This covers application set up, probing advice and material selection.

- Worldwide sales and support networks, with offices in 36 countries.

- Stock held around the world, ensuring rapid local delivery.

- An Online store with 9 transactional sites around the world.

What is a stylus?

A stylus is the part of the measuring system which makes contact with the component, causing the probe's mechanism to displace. The generated signal enables a measurement to be taken.

The stylus is the first link with the work piece. This is why it is vital that the stylus delivers the greatest possible accuracy at the point of contact.

The feature to be inspected dictates the type and size of stylus used. In all cases, however, maximum rigidity of the stylus and perfect sphericity of the tip are vital.

The importance of styli for precision

Successful gauging depends very much on the ability of the probe's stylus to access a feature and then maintain accuracy at the point of contact.

The performance of your gauging can easily be degraded if you use a stylus with poor ball roundness, poor ball location, bad thread fit or a compromised design that allows excessive bending during measurement.

At Renishaw, we have expertise in probe and stylus design to develop a comprehensive range of CMM and machine tool styli to offer you the greatest possible precision.

Top tips for using styli:

- Use genuine Renishaw styli.

- Always use styli that are as short and stable as possible.

- Use the largest ball possible.

- Are you using components that are thermally stable? Bear in mind the ambient conditions.

- When putting together styli configurations, refer to the permitted masses as specified by the probe manufacturer.

- Use the lowest possible number of separate components.

Styli for ZEISS probes

Renishaw has extended its comprehensive styli catalogue with the introduction of a range of precision styli, adaptors and accessories for the ZEISS range of probe heads. You can search by shape type and view the range on our Online store.

As a supplier of probe systems for selected ZEISS CMMs, Renishaw has increased its range to enable users of all ZEISS machines to benefit from the high precision specifications associated with all Renishaw styli.

The range is compatible with ZEISS analogue probe systems without probe changing, measuring heads with probe changers and dynamic probe heads.

Accessories

Aside from the hundreds of available styli in the ZEISS range, Renishaw also supplies a wide variety of accessories for the ZEISS range of probe heads. This includes styli holders and extensions, knuckles, cubes, adaptors, as well as an assortment of other tools and accessories.

ZEISS Vast XXT adaptor plates and styli

We are pleased to announce the introduction of styli and adaptor plates for the ZEISS Vast XXT scanning sensor. TL1, TL2 and TL3 adaptor plates are available along with a vast selection of M3 styli designed specifically for these plates.

Renishaw styli for FARO® arms

Renishaw has further extended its comprehensive stylus catalogue to include a range of styli, specific for use on the FARO arm probes. You can view the range on our Online store.

These styli have been designed especially for use on FARO portable arm CMMs and are available in a range of different diameters. Their robust design and construction utilises grade 5 zirconia balls that have a high fracture toughness.

Zirconia is a particularly tough ceramic material with hardness and wear characteristics approaching those of ruby. Its surface properties make it an ideal material for aggressive scanning applications on cast iron components.

The balls are bonded to the high strength tungsten carbide stem with impact resistant adhesive, and specialist construction techniques have been incorporated to ensure that the joint between the body and stem is extremely rigid and virtually indestructible.

Renishaw styli for FARO probes are available in both 11/4-20 UN and M6 thread sizes.

Accessories

Renishaw also provides a range of different accessories. These include a comprehensive kit, extensions, screws and adaptors, as well as metrology fixturing components and metrology fixture tables.

Service and support

Renishaw's expansion over 50 years has always been accompanied by a willingness to invest in a worldwide sales and support network. Today, this includes offices in more than 36 countries, plus a global network of distributors and agents.

The benefit to our customers is that at any time, there are in excess of 100,000 styli held in stock locations around the world, ensuring rapid local delivery.

We have earned an enviable reputation for our commitment to customer care and support. Should technical advice be required, or a problem arises, our global network of staff is always available to offer advice and recommend a suitable replacement.

Precision styli education guide

Discover in our brochure key technical information on selecting and using the correct type, materials, design and calibration.

FAQs

View the frequently asked questions for Renishaw styli.

Why are there different types of styli?

The comprehensive range of genuine Renishaw styli comprises a range of configurations to suit different measurement applications. All components, including stylus balls, are available in a range of materials. Please download our Precision styli guide to learn more.

How do you know you are using a genuine Renishaw stylus?

The majority of our styli have the Renishaw logo printed onto the holder. They are all supplied in plastic boxes with holographic labels. To ensure the integrity of the data you gather, make certain that you specify and use a stylus from the comprehensive range of genuine Renishaw styli.

Are Renishaw styli RoHS compliant?

The styli range of products are RoHS compliant. Please read our full statement.

What is the smallest styli ball diameter we can produce?

0.3 mm as standard. We have a dedicated custom styli design service, where our experts can develop a product that satisfies customer demand for accuracy, piece part inspection, delivery and cost.

How can I tell if my stylus has a grade 3 ruby ball?

At Renishaw, our high accuracy styli have a titanium nitride coated (gold coloured) holder. This enables the user to identify the grade 3 stylus from our standard grade 5 range.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.