Renishaw helps position INEOS Britannia for sustainable success

Background

Renishaw, the global engineering company, is an official technical partner of the British sailing team, INEOS Britannia, which is the Challenger of Record for the 37th America's Cup.

Led by former Olympic champion Sir Ben Ainslie, the team will attempt to become the first British yacht to win the America's Cup in its 172-year history. The competition takes place in Barcelona, Spain, between August and October 2024.

Renishaw has supported the British challenger for the America's Cup since 2016. For the current campaign, Renishaw supplies INEOS Britannia with magnetic encoder solutions and additively manufactured parts, plus expertise in position measurement and Raman spectroscopy.

Sir Ben now leads his third consecutive British challenge in the America's Cup and looks forward to the Challenger Selection Series (Louis Vuitton Cup) in September 2024, where the elite of world sailing compete to determine who will face the defending champions, Emirates Team New Zealand, in the final America's Cup match starting October 12th 2024.

AC75 boats

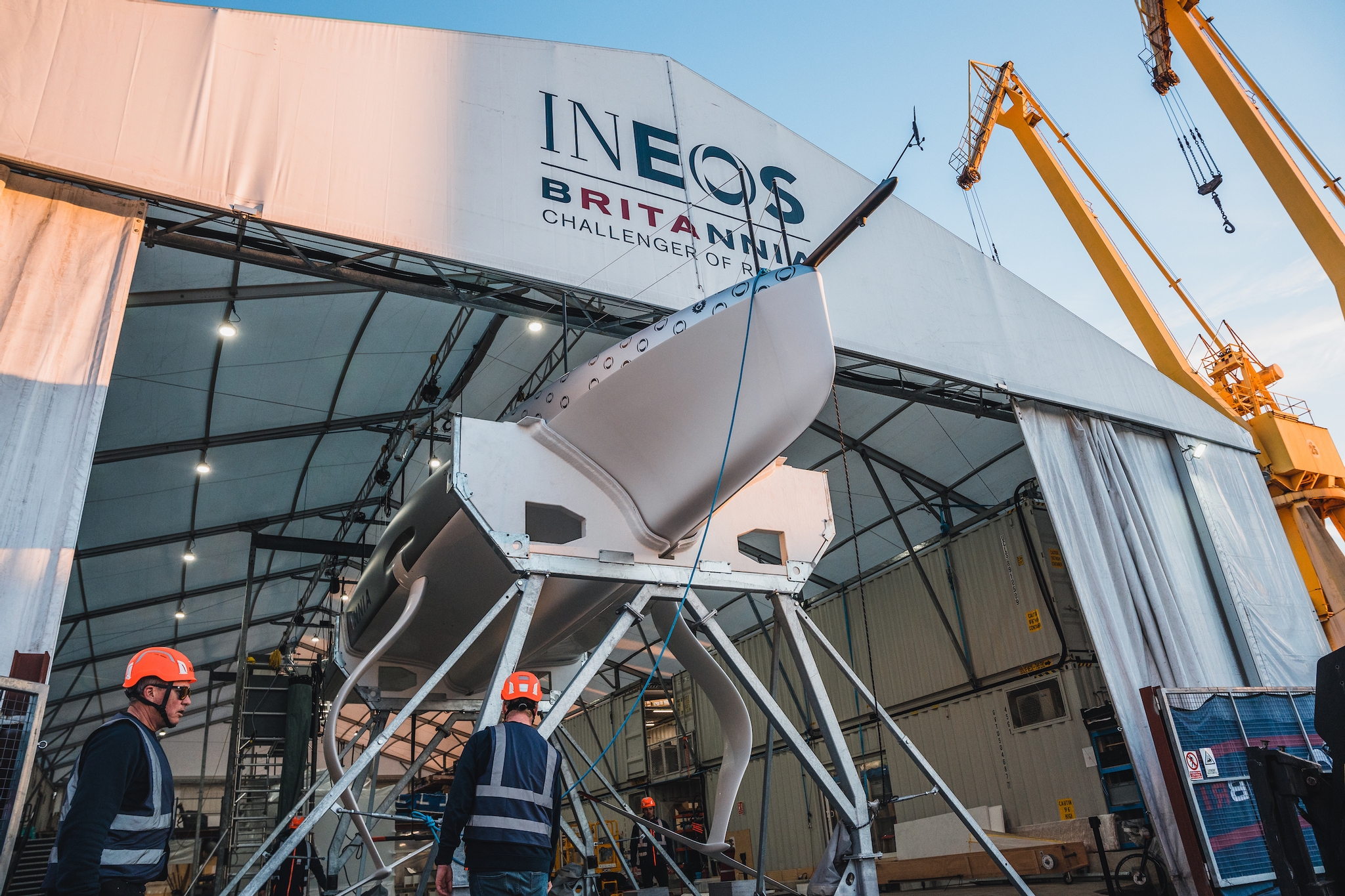

The AC75 is an advanced composite racing yacht used in America's Cup matches since 2021. The 23-metre foiling monohull features three sailing hydrofoils mounted on the hull, a soft wingsail, and no keel.

Sir Jim Ratcliffe, CEO of INEOS, and Sir Ben Ainslie

INEOS Britannia RB3 race boat

Challenge

The Cup will see teams racing in AC75s at speeds of up to 60 miles per hour. To showcase sustainable innovation, all teams involved have adapted their boats in accordance with the shared sustainability goals written into the America's Cup rules.

For example, INEOS Britannia has reduced its consumption of new carbon fibre in the construction of race boat ‘Britannia' by using recycled carbon from British-based recovery plant, ELG Carbon Fibre.

Sustainability rules have reduced the size and weight of the America's Cup boats compared to most previous generations. Now, teams can only build one boat, and with the same class being used for the next America's Cup in 2027, there are opportunities for teams to re-use components in the next Cup cycle.

Michel Marie, manufacturing manager at INEOS Britannia, explains: "Ahead of this competition, we've focused heavily on sustainability and committed to using recycled materials to set an example in the sporting world. Knowing that Renishaw has also committed to extensive Net Zero goals and is taking steps to reduce emissions gives us the confidence that we can continue to improve sustainability in our efforts to win the Cup."

Dr Finlay Evans

Solution

For the previous campaign, Principal Engineer Dr Finlay Evans and his team at Renishaw designed special rotary sensors with built-in magnetic encoders that were integrated into the boat's helm controls.

This time around, INEOS Britannia wanted a much smaller version of the sensor for their race boat and Dr Evans started with electronic improvements to miniaturise the encoder, while improving overall electrical resilience.

These changes included substituting the RLS RM08 chip encoder with the latest RLS AM4096 chip, adding reverse voltage and over-voltage protection, and increasing the level of electrostatic discharge (ESD) protection. The team also changed the PCB layout to a flexi-rigid PCB design, which reduced the overall packaged size and allowed the addition of an LED status indicator.

The new compact sensor is also fully encapsulated and watertight to ensure shock-protection and to eliminate the risk of saltwater ingress. As in the previous version, the sensor uses the CAN bus communication protocol — an industry standard technology providing robust communication in harsh conditions that enables simplified and efficient cabling on the boat. Improved sensor firmware enhances the encoder's functionality to include both rotary position and velocity feedback.

The external indicator gives a simple visual confirmation of correct operation to aid installation and setup. Furthermore, the sensor can also be reconfigured on-the-fly using the CAN bus message structure, which makes on-the-boat configuration changes faster and easier.

About the RLS AM4096 rotary encoder

Manufactured by Renishaw's Slovenian-based associate company, RLS, the AM4096 encoder can be used in a wide range of non-contact position or velocity measurement applications such as motor control and commutation, robotics, camera positioning, and other demanding high resolution applications.

Encoder features and benefits include contactless angular position measurement, selectable resolutions to 12-bits, programmable zero position, SSOP28 or QFN32 chip package options, high-speed operation and integrated EEPROM (a type of programmable memory).

Andy McLean, Lead Systems Engineer for INEOS Britannia, explains how the encoders control the boat:

There are thirty twist grips on the boat each with an encoder — that is our primary method for control. We have split the control system into hydrodynamic and aerodynamic controls. Four sailors use the twist grips to control the roll, pitch, heave and acceleration of the yacht.

A big change has been the aerodynamics. Last time, the sailors were standing up in the [AC50] boat and leaning over the side. Now, they all sit in tight cockpits with aero fairings around them. Everything is packaged smaller; the steering wheel and controls are smaller. So, there was a big drive to shrink the encoders as well.

Andy Mclean, Lead Systems Engineer for INEOS Britannia

Results

Andy McLean has been impressed by the support that Dr Evans and his team have provided over the course of the 37th America's Cup.

“Renishaw is fundamentally at the interface between the sailor and the yacht. All our control signals go through these encoders into the control system. That is a significant piece of our puzzle and one which we have to trust, because boats can capsize, and water ingress is one of our biggest challenges. The real advantage of the new sensor design is that the packaging size has come down so much. It allows us to create better ergonomics for the sailors, so that the controls become more natural.”

Andy continues to highlight the vital role that encoders play in ensuring boat safety.

"The class rule is not lenient, everything we do is about reducing mass. The composite structure of the boat is highly optimised. For example, if an encoder failed and the sailor lost control of the rudder, the boat could nosedive and be written off on impact with the water. It's equivalent to the brake pedal on a Formula One car."

Lighter and smaller twist sensors on the INEOS Britannia race boat have helped to minimise the space needed for the helm and flight controls which improves aerodynamics and saves weight.

INEOS Britannia boat hull

The sustainability rule

An updated ‘Version 2' of the Protocol and AC75 Class Rule specifies the latest requirements for America's Cup competitors and includes: permission to only build a single AC75 boat, rule incentives for sustainability initiatives in construction of the hull, limitations on the quantity of foils and componentry that can be used for the AC75 design, a reduction in the number of crew onboard from eleven (on the AC72 class) to eight sailors, and the use of the AC75 class of boat in races for the 38th America's Cup.

Summary

In the previous campaign, Dr Evans and his team at Renishaw devised specialised rotary sensors equipped with built-in magnetic encoders. These sensors (twist grips) were seamlessly integrated into the boat's helm controls.

For the 37th America's Cup, INEOS Britannia sought a more compact version for their racing boat. The evolution of the sensor design reflects the relentless pursuit of precision and efficiency in high-performance sailing.