Probing solutions for industrial automation

What does RCS P-series do?

RCS P-series probing solution applies metrology principles to your robot cell to enable in-process monitoring and automatic recovery. Multiple probe options are available based on the requirements of the cell, with radio, hard-wired or optical transmission available.

Find support for RCS P-series

Understand more about the RCS P-series probing solution

The probing solution forms part of the wider RCS series of industrial automation products and software.

Discover the benefits of RCS P-series

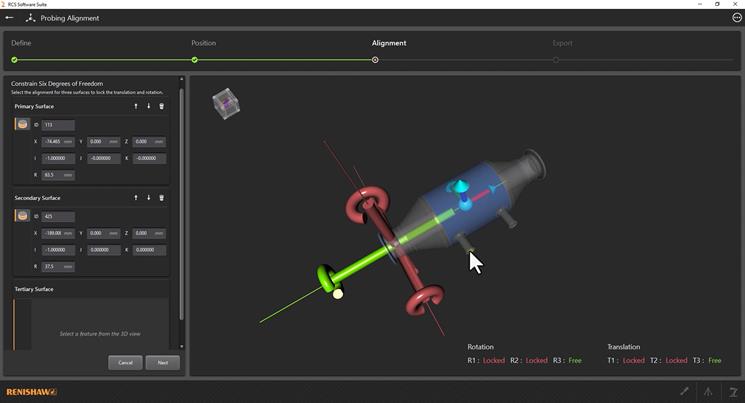

RCS P-series enables a number of advanced calibration and datum functions, customisable for any robot cell. All cell components calibrated in six degrees of freedom (DoF) relative to each other can be understood. Users can utilise in-process path correction and experience benefits such as:

Recover your cell with ease

Minimise downtime by automatically recovering after collisions and tracking trends in the cell over time.

Offline programming

Connect the digital and physical worlds using a simple alignment routine, reducing the need to reprogram.

Simplify steps to integrate

Easily set-up a datum with the RCS Software Suite. Make probe installation accessible to all system integrators.

Our range of probes for robots

The RCS P-series offers a range of probing options for your specific robot cell requirements. You can choose hard-wired or wireless options, both with or without a tool setter. You can also include an RCS P-series RPU - a controller which interfaces directly with the robot controller for probe calibration and metrology calculations.

Hard-wired probe

Select the most straightforward option for when a wired probe suits your cell.

Radio probe

Integrate probing within industrial robotics using a radio (wireless) probe and receiver.

Optical probe

For when your cell requires a wireless probing option and line of sight to a receiver is achievable.

Tool setter probe

A tool setter probe is used to update tool frames or to detect broken tools.

Upgrade your core licence to include the advanced probing option

This allows complex alignment strategies to be implemented on your RPU. They can be designed in the datum builder section of the software.

Enable machining on your robot with RCS spindle calibration

Automatically calibrate spindles using a Renishaw toolsetter with an RCS spindle calibration disc stylus. Achieve 5 DoF calibration with several quick orientations.

RCS P-series FAQs

Why is the RCS RPU required?

The RCS P-series is able to operate seamlessly with the robot controller due to the connection with the RCS RPU. The RCS RPU contains probing-specific macros and a proprietary calibration framework to perform the routines autonomously. This simplifies installation and allows full 6 DoF control of the robot-mounted probe.

Do users need to reprogram following a collision?

No, RCS P-series provides a solution to handle the correction and recovery of a cell seamlessly. This saves a large amount of time and effort. There is no need to re-teach the robot program following any collision, maintenance or movement of the robot.

Downloads

-

Brochure: Advancing robotic automation - RCS P-series

[12.1MB]

Brochure: Advancing robotic automation - RCS P-series

[12.1MB]

-

Flyer: RCS spindle calibration kit

[1.3MB]

Flyer: RCS spindle calibration kit

[1.3MB]

-

User guide: RCS P-series User Guide

[1.1MB]

User guide: RCS P-series User Guide

[1.1MB]

-

User guide: RCS P-series macro instructions for Fanuc robot controllers

[1.5MB]

User guide: RCS P-series macro instructions for Fanuc robot controllers

[1.5MB]

-

User guide: RCS P-series macro instructions for KUKA robot controllers

[1.5MB]

User guide: RCS P-series macro instructions for KUKA robot controllers

[1.5MB]

-

User guide: RCS P-series macro instructions for ABB robot controllers

[1.3MB]

User guide: RCS P-series macro instructions for ABB robot controllers

[1.3MB]

Enquire about RCS P-series

Complete the form below to enquire about purchasing options or to receive more information about RCS P-series.