ONENG partners with Renishaw to build new advanced motion stages for semiconductor industry

Background

In the rapidly evolving world of advanced technology, motion stages have traditionally been associated with high performance process equipment for applications such as semiconductor manufacturing.

Now, as the global market expands and competition grows, new applications like industrial automation and advanced machining processes are driving a surge in demand for high-quality, versatile motion stages.

Recognising the importance of a reliable partner, ONENG, a prominent South Korean producer of motion stages and equipment, has chosen to collaborate with Renishaw.

By leveraging Renishaw's diverse range of optical encoders and extensive expertise in motion control, ONENG aims to enhance their capabilities and provide even better solutions to their customers.

Challenge

To remain competitive, system integrators and component manufacturers face the task of trying to optimise machine design objectives such as size, mass, performance, reliability, and cost-efficiency.

Precision motion stages are primarily supplied to system integrators in industries such as semiconductor, flat panel display (FPD), and electronics. Once integrated, they become a crucial part of the advanced process equipment sold to major original equipment manufacturers (OEMs) worldwide.

Automatic optical inspection (AOI)

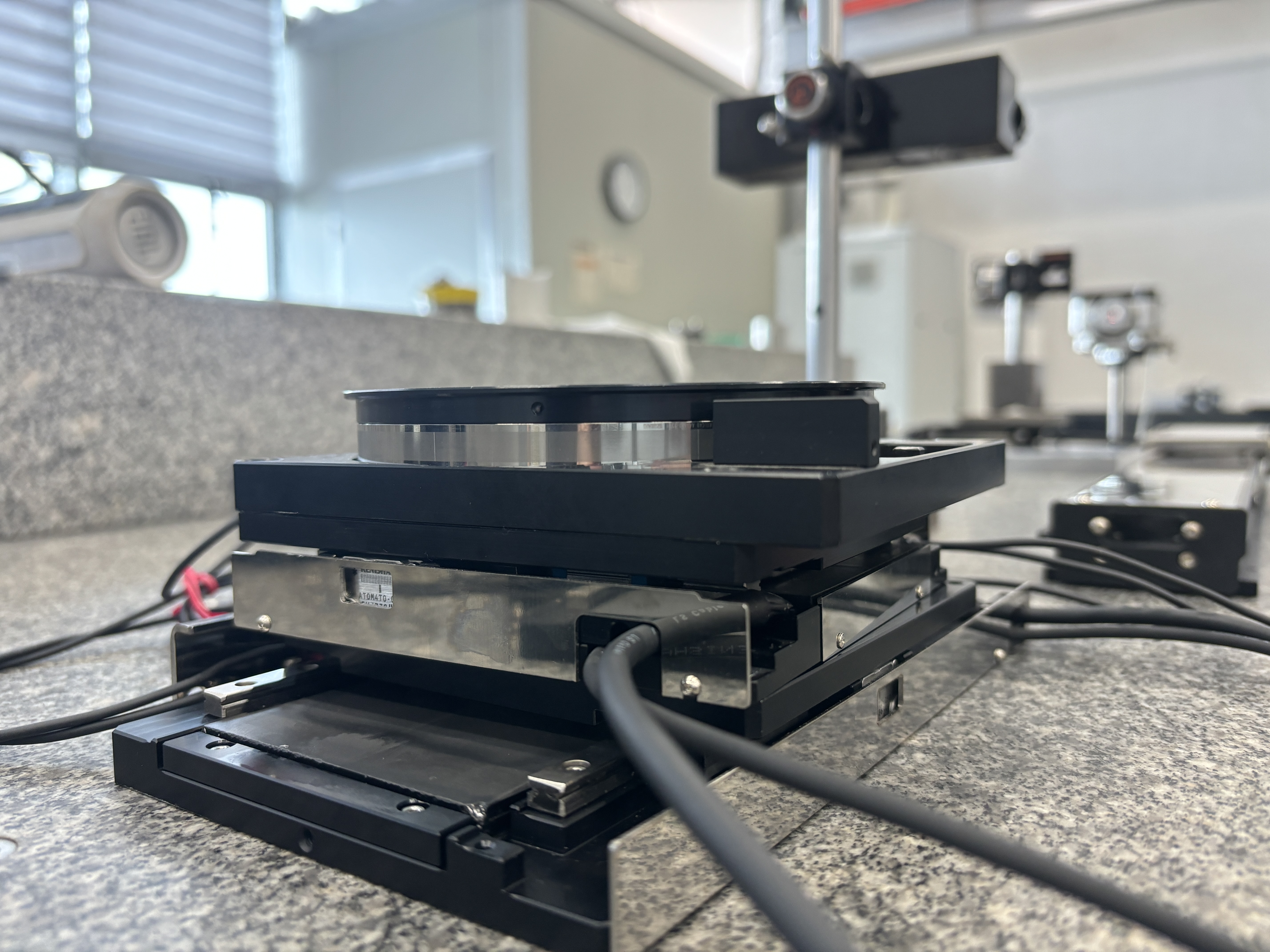

ONENG motion stage with ATOM encoder

Due to the variety in process machinery design, subsystems such as motion stages require high levels of customisation to meet the unique needs of different customers.

ONENG has been successful in providing custom-built solutions to several well-known Korean manufacturers. Most of their orders involve customised motion stages that have been designed and manufactured to the specific requirements of system integrators.

Mr. Yoon Seok Han, Director of ONENG, highlights the applications of Renishaw's optical encoders:

"One of the major challenges in the manufacturing of custom products is the need for close collaboration with component suppliers to ensure diverse product options and relevant technical support. Renishaw's optical encoders cover linear, rotary, and partial arc applications — providing us with greater flexibility in designing our products."

Renishaw optical encoders have had an excellent reputation in the market for many years. The main reason for our long-term cooperation with Renishaw is their outstanding technical support. Their technical team has a deep understanding of motion stage technologies; they recommended the optimum optical encoder solutions — enabling our motion control products to stay competitive and relevant in the market.

ONENG (South Korea)

Solution

ONENG has engineered a diverse range of motion stages, including large platforms with travel lengths up to 10 m and micro positioning stages with travel down to 2 mm.

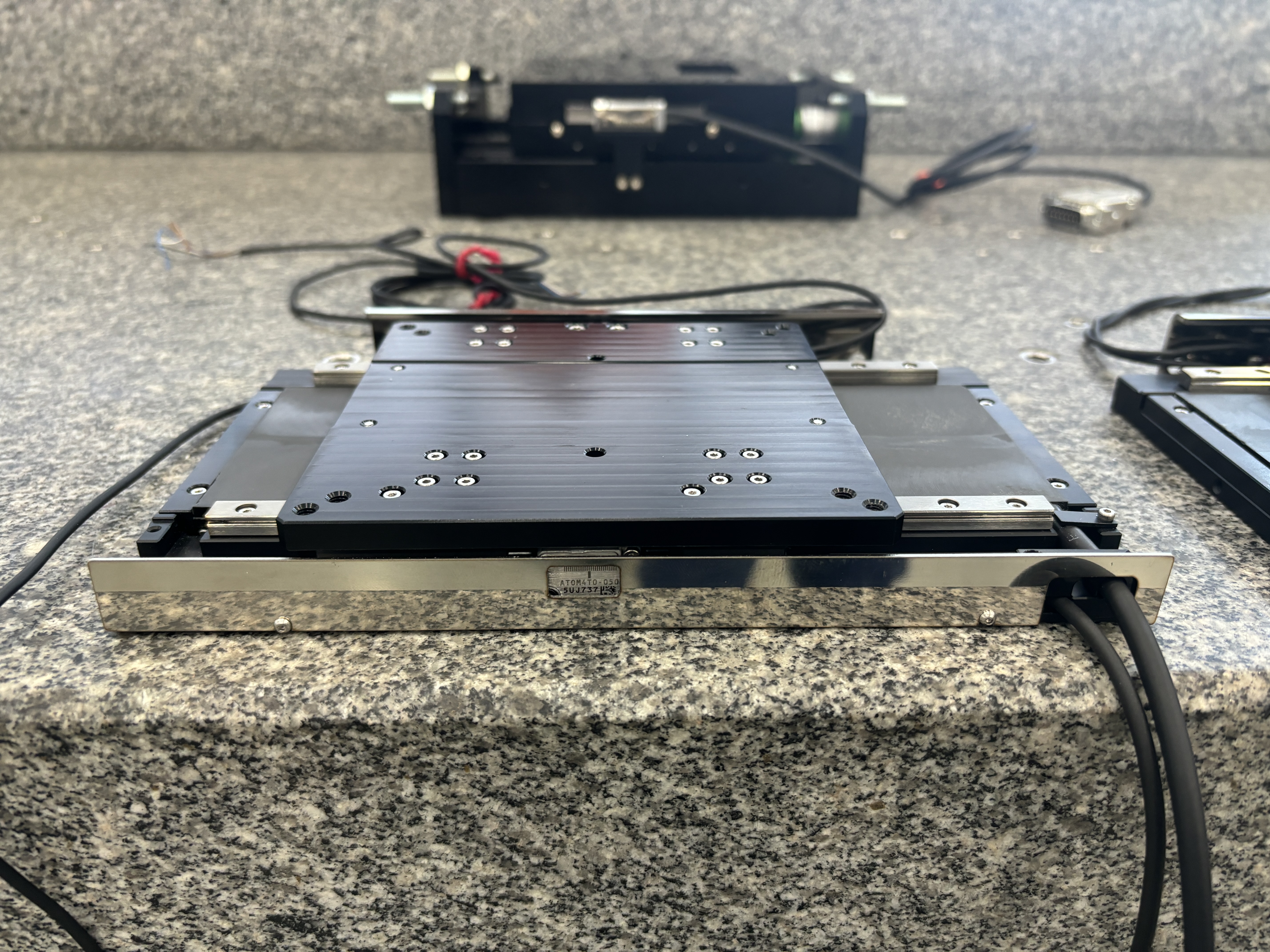

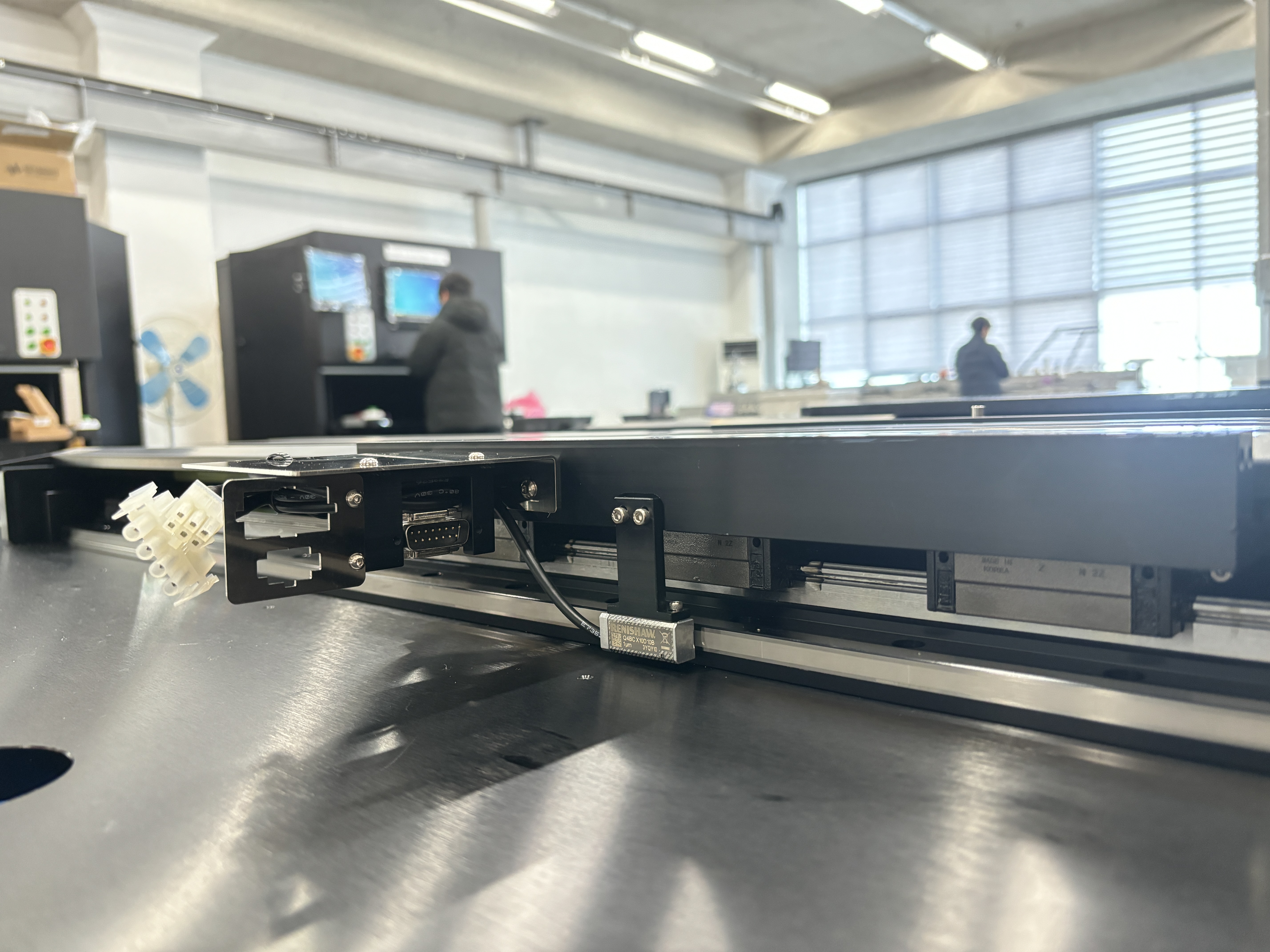

These precision motion stages leverage Renishaw's QUANTiC™ and ATOM™ series optical encoders, which offer digital output and high resolutions.

For the semiconductor industry, ONENG has introduced a compact linear stage featuring Renishaw's ATOM miniature optical encoder. This stage is designed for the precise positioning control of pick-and-place machines. During die bonding — part of the semiconductor packaging process — the vacuum nozzles of the die bonder move at high speed to pick up chips and place them with high precision and accuracy.

Additionally, ONENG has developed multi-axis miniature stages that incorporate partial arc optical encoders, which measure a partial arc of rotation using scale wrapped around a shaft or arc. One such stage features the QUANTiC encoder readhead and RKLC40-S stainless steel scale, offering an angular range of 270˚.

The RKLC encoder scale is a robust, 6 mm wide stainless steel tape with a thickness of just 0.15 mm. This thin profile allows the scale, when rigidly fixed to a machine axis, to match the coefficient of thermal expansion (CTE) of the machine substrate. It also facilitates installation in space constrained applications.

ONENG linear stage with ATOM encoder

ONENG also develops motion stages for automated optical inspection (AOI) equipment — one application is in the inspection of automotive lighting devices for appearance, brightness, and defects. ONENG ultra precision stages use a dual-track design equipped with Renishaw's QUANTiC optical encoder series.

Renishaw offers a range of laser interferometer and ballbar measurement products that enable customers to enhance the static and dynamic performance of their motion systems.

The Renishaw XL-80 laser interferometer has been chosen for the measurement and calibration of each linear motion stage to ensure high quality and accuracy during production and commissioning. ONENG plan to add the XR20 rotary calibrator to their suite of calibration products — providing a comprehensive inspection solution for rotational axes.

Results

ONENG has worked with Renishaw to enhance its capabilities in the advanced technology sector, particularly for semiconductor manufacturing and industrial automation.

Manufacturers encounter several challenges when specifying optical encoders such as —

- The different speed and noise trade-offs when choosing between analogue and digital output.

- Achieving low jitter for precise position control in high-speed applications like semiconductor manufacturing.

- Minimising the size and mass of components in compact micro linear stages to improve stability and performance.

Additionally, equipment must meet international or local safety certifications such as EMC and RoHS.

QUANTiC encoder readhead

ONENG aims to be a key player in markets for advanced semiconductor equipment, specialised motors and motion control. They also plan to build an ultra-precision automation system for high performance products using Renishaw's encoders.

Mr. Yoon explains: “Renishaw optical encoders have had an excellent reputation in the market for many years. The main reason for our long-term cooperation with Renishaw is their outstanding technical support. Their technical team has a deep understanding of motion stage technologies and closely tracks the latest market trends. They recommended the optimum optical encoder solutions — enabling our motion control products to stay competitive and relevant in the market.

In addition, Renishaw has reliable and stable delivery schedules. For motion stage projects, the time from a customer placing an order to delivery typically only takes 2 to 3 months.

Renishaw's metrology products combined with excellent technical support and global sales support have helped ONENG to remain competitive offering reliable delivery schedules and tailored metrology solutions for high-precision motion stages.

ONENG linear stage with QUANTiC encoder