Laser encoder applications

Discover how Renishaw laser encoders or displacement interferometers are used in applications where the highest levels of accuracy are required.

Fibre optic laser encoders - Semiconductor

Application details

The semiconductor industry is known for its fast moving development cycles to produce smaller, faster and lower cost chips. One element of meeting these targets is to deliver highly efficient manufacturing processes which sustain exceptional levels of quality.

Laser encoder systems are widely used within the semiconductor industry to help achieve these targets, by providing the ultimate in accuracy for key manufacturing and inspection processes.

Application advantages

| Key requirements | Renishaw's solution |

| Nanometer levels of accuracy | The RLD10-X3-DI differential interferometer measurement head allows for direct measurements between the column and stage or vacuum applications. |

| Sub-nanometer repeatability | Renishaw's RLU20 provides exceptional laser frequency stability which delivers the ultimate repeatability in vacuum applications. |

| Pico-meter resolutions | Using Renishaw's RPI20 it is possible to achieve resolutions up to 38.6 pm in a 36-parallel bit format. |

Experience

Laser encoder or displacement interferometer systems have been used within the Semiconductor industry for a number of years. Renishaw has been providing laser encoder solutions to semiconductor OEM's since 2005 and has a proven history within this sector collaborating and supporting equipment manufacturers.

Fibre optic laser encoders - Synchrotron

Application details

Synchrotron's are a particular type of particle accelerator used in scientific research to conduct various experiments. Each of these experiments provide their own unique challenges, such as high precision motion control systems, vibration analysis or drift measurements. Laser encoders or displacement sensors are used within these experiments depending on the requirements.

Application advantages

| Key requirements | Renishaw's solutions |

| Easy to align and install | Renishaw's RLD's are fitted with beam-steering optics, this combined with the fibre optic laser unit results in an easy system to set-up and align. |

| High update rates | Through the RSU10 USB interface is capable of a maximum update rate of 50 kHz, which can either be used with Renishaw standard software packages or custom solutions using the freely available SDK. |

| Knowledge sharing and working partnerships | Understand and defining what needs to be measured is often the first challenge, Renishaw has a strong history in developing working partnerships with its customers to provide them with the best solution. |

Experience

Synchrotrons are located all around the world and are available in a number of different sizes. Renishaw have had the opportunity to work with a number of these institutes to develop a practical and feasible solution which often exceeds the initial requirements.

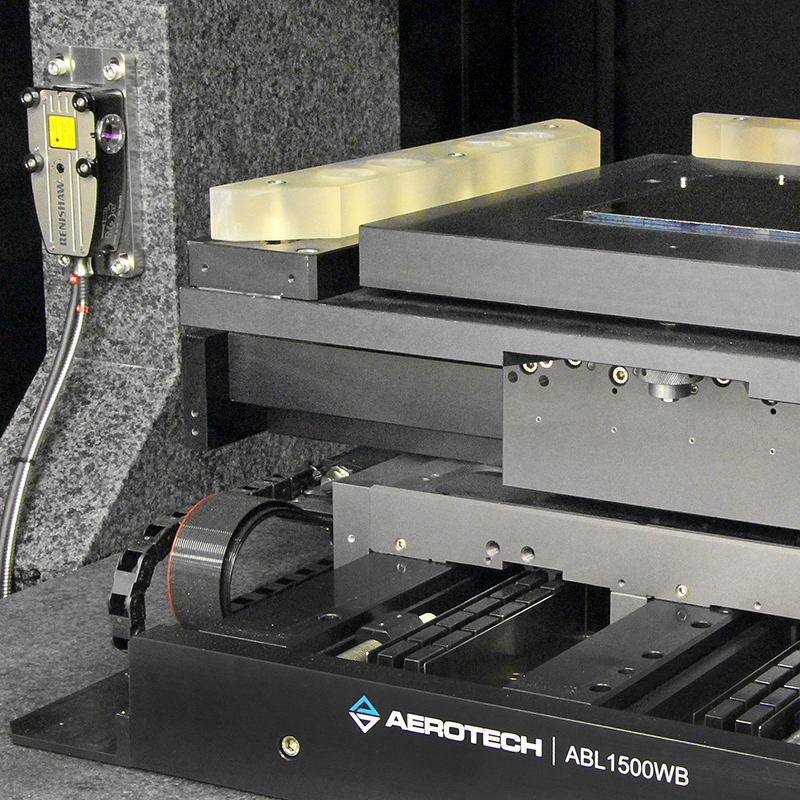

Fibre optic laser encoders - XY stages

Application details

XY stages are used within a vast variety of applications from high volume manufacturing through to test and research equipment. XY stages typically suffer from the effect of Abbe errors, these are angular errors within the stage which can result in large positional errors at the top of the stage. Through using interferometric encoder systems and measuring at the point of interest it is possible to eliminate the effect of these error sources.

Application advantages

| Key requirements | Renishaw's solution |

| Eliminating Abbe or stage errors | Renishaw's RLE system, with its compact detector heads, allows for easy mounting near to the stage. This ensures that a direct measurement at the point of interest can be easily achieved. |

| Remote heat source | Laser sources typically generate a lot of heat. With the fibre based delivery that Renishaw offers allowing for the laser unit (RLU) to be mounted either 3m or 6m from the working area, therefore preventing localised heating. |

| Simple integration and set-up | Interferometer based systems are typically difficult to integrate and set-up. By developing a fibre based solution with a compact interferometer and detection scheme Renishaw have combined the measurement performance of interferometer encoders with the ease of installation of commonly used with typical optical encoders. |

Experience

Renishaw have over 20 years of experience integrating interferometer based encoder solutions into a vast range of applications from the harsh environments of CNC machine shops through to the demanding performance requirements of the semiconductor industry.

This experience has evolved from working with a number of OEM's and stage builders and developing these close partnerships. Assisting with the integration of interferometer encoder systems into their next generation product resulting in consistently advancing technology.

Image courtesy of Aerotech.

Long range laser encoders - Aerospace

Application details

The aerospace industry is driven by achieving tight tolerances on the largest of parts, by using laser interferometer based encoder solutions it has been possible to achieve this. On large CNC machines which are typically used for wing spars or fuselages the longer machines axes often need to be 30 m or more in length, Renishaw's HS20 system in combination the RCU10 compensator is capable of achieving an accuracy of ±30 µm over a 30 m axis.

Application advantages

| Key requirements | Renishaw's solution |

| Long range measurement in harsh environments | Renishaw's HS20 laser head is capable of measurement distances up to 60 m. With a proven history of reliable operation in the most challenging conditions, HS20 maintains its position as the market leader in this field. |

| Non-contact measurement system | Using a direct measurement eliminates the errors found in rack and pinion or ball screw feedback systems, such as hysteresis, backlash, mechanical wear and cyclic errors. |

| Workpiece and machine structure compensation | The RCU10 compensation system contains integrated modules which are designed for thermal expansion and contraction of the machine structure and workpiece, therefore maintaining accuracy over long machining cycles. |

Experience

Working with aerospace manufacturers and large CNC machine builders from around the world Renishaw has a substantial number of laser interferometer systems installed and in use today.

These interferometer based systems are used on the machines for machining aircraft spec alloy materials, through to the carbon fibre composites used on today's modern aircraft. All of these applications demand the tightest tolerances on the largest of parts, which is easily achievable with Renishaw's interferometer based encoder systems.

Long range laser encoders - CMM

Application details

Coordinate measuring machines (CMM's) typically use optical encoders, however for larger CMM's where accurate and repeatable performance are required, laser interferometer encoders are a growing choice within this market.

CMM's are typically a gantry based design, on larger CMM's the skew error generated from this gantry can result in large positional errors. However using interferometer encoders at the top of the gantry it is possible to eliminate skew errors.

Application advantages

| Key requirements | Renishaw's solution |

| Long range measurements | Renishaw's laser encoder options are capable of long range measurement of up to 60 m with HS20 and 4 m with RLE. |

| Point of interest | The key advantages of laser interferometer encoder systems is being able to easily measure at the point of interest. |

| Easy installation and alignment | Renishaw systems use a visible light source which when combined with a simple 0 to 1V output from the laser source for signal strength ensure easy installation and alignment. |

Experience

Renishaw has developed a number of relationships through working together with OEM's, providing configurations capable of achieving the customers specified measurement performance. Understanding the metrology framework of the machine is critical the developing a correct solution.

Long range laser encoder - LCD

Application details

As technology within the LCD industry develops so does the machines used to manufacture and inspect these products. Large screen sizes with small feature sizes results in higher performance from the metrology system on the machine. Laser encoders provide a solution capable of meeting these requirements

Application advantages

| Key requirements | Renishaw's solution |

| Point of interest | For large XY stage applications where inherited Abbe errors affect the precision of the machine. Renishaw's laser encoder solutions allow for direct measurement at the point of interest. |

| Proven technology within similar industries | Renishaw laser encoder solutions have been used within the semiconductor industry for a number of years, where they have proven reliable and are capable of delivering the same level of performance as new, even after years of continual use. |

| High performance measurements | With analogue signal periods of 158 or 316 nm laser interferometer encoders are capable of delivering interpolated pico-meter resolutions. |

Experience

The experience that Renishaw has gained in working with OEM's and stage builders is being used to minimise integration time. Experience and knowledge in these different applications, means that we can quickly identify the most suitable interferometric encoder system for your application.

Explore our why user a laser encoder web page to gain a better understanding of how our products work and how they can improve your processes.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.