AGILITY® CMMs with 5-axis technology

AGILITY® CMMs deliver REVO® 5-axis measurement speed, accuracy and flexibility to the shop floor and the lab, with Renishaw's manufacturing quality and innovative technology.

The AGILITY range of CMMs will help to increase the throughput and quality of your manufacturing with fully integrated dimensional measurement and surface roughness inspection. From the use of high-quality materials and components to the full optimisation of 5-axis measurement technology, AGILITY CMMs provide a high-speed, high-performance solution for the shop floor or metrology lab.

AGILITY CMMs bring together the pioneering technology and high-quality manufacturing that have gained Renishaw an unrivalled reputation for innovation in the most demanding industry sectors. The machines are designed to deliver all the advantages of the REVO multi-sensor 5-axis measurement system, including:

- 15% to 50% cycle time savings, compared to 3-axis measurement systems

- Integrated dimensional inspection and surface roughness measurement

- Infinite positioning for superior feature access

AGILITY S 5-axis multi-sensor CMMs are highly capable and robust solutions for inspection on the shop floor.

AGILITY® L CMMs with 5-axis multi-sensor technology provide high-performance inspection in laboratories and clean rooms.

Introducing AGILITY CMMs

AGILITY S 5-axis multi-sensor CMMs for the shop floor

Designed for shop floor environments

The S range of CMMs provides the ability to accurately measure parts in shop floor environments without temperature control. The rapid data capture speeds provided by 5-axis measurement reduce inspection cycle times, helping production departments keep pace with high volume manufacture. The systems work well in both stand-alone and fully automated production lines.

Rapid results at the point of manufacture

Results are captured at, or close to the point of manufacture, so production decisions can be made much faster. This replaces the traditional method of routing parts to centralised inspection facilities, reducing time and cost to the part and the risk associated with part handling.

Reducing operations

The multi-sensor capability of the system allows users to combine multiple checks in one automated part program. This gives production departments the ability to report on dimensional features and surface roughness callouts. AGILITY CMMs therefore minimise footprint and simplify measurement processes.

AGILITY L CMMs with 5-axis multi-sensor technology for laboratories

Premium accuracy

The L range of CMMs delivers the performance needed by manufacturers operating in the top end of aerospace, automotive, consumer electronics and other precision engineering sectors. The most accurate machine has sub-micron accuracy, and even the largest L 163512 is specified at under 2 µm.

High throughput

The 5-axis functionality helps meet the throughput challenges of a machine operating in a controlled environment as an integral part of the manufacturing process. Fast inspection turnaround of development parts and production samples ensures verification is as efficient as possible.

Ultimate multi-sensor flexibility

Combining the infinite positioning of the REVO probe head with the most comprehensive range of sensors, AGILITY L machines are an ideal platform for developing new products and manufacturing processes. The surface finish probe will reach features previously inaccessible. The non-contact sensors will capture surface data without touching the part. The ultrasonic thickness probe simplifies inspection routines and often eliminates the need for part reorientation.

A range of CMMs with enhanced reliability, capability and precision

The range of AGILITY CMMs enhances the design and production capabilities of manufacturers globally. The machines provide a first-class metrology solution to meet the demanding performance requirements of manufacturers in aerospace, automotive, medical and many other safety-critical industries.

Renishaw also provides CMM probes, software and retrofits to ensure solutions to a range of manufacturing issues.

AGILITY CMM systems eBook

AGILITY CMMs have been designed and made for speed and accuracy, building on Renishaw's unrivalled reputation for innovation in the most demanding industry sectors.

Access an in-depth presentation of the benefits AGILITY CMMs can deliver to your business.

Request the eBook

Designed for reliability

Maximum uptime and performance

Renishaw Lightning Drive™ brushless linear motors deliver smooth, backlash-free axial motion without complicated drive belt mechanisms that can wear over time. Friction and noise are significantly reduced, providing unrivalled reliability and performance.

Reduced maintenance and extended life

Renishaw's UCC 5-axis control system minimises machine motion throughout the inspection cycle. This allows the REVO head to do most of the work, removing detrimental accelerations and decelerations of the machine structure.

Environmental protection

AGILITY CMMs feature elevated and enclosed Y-axis drive systems to protect components from airborne contaminants in uncontrolled environments. The drive system's location also keeps the machine's loading area free from critical metrology components that could be accidentally damaged.

Designed for capability

Flexible rack positioning

Multiple mounting positions on AGILITY CMMs offer complete flexibility when choosing locations for rack systems.

Additionally, a side-mounted option provides a clear pathway through the machine for loading systems.

Fully usable measuring volume

AGILITY S shop floor CMMs have variants with a raised working space to allow the use of loading systems or rotary tables without reducing the available measuring volume.

Designed using Renishaw's precision technology

Perfect positioning

Renishaw's VIONiC™ readheads and thermally stable scale, with precision temperature sensors, minimise thermal error throughout the measuring volume.

Industry-leading calibration and verification

All AGILITY CMMs are mapped, verified and serviced using Renishaw's XM-600 or XL-80 calibration systems.

Optimal material selection

The use of granite for the stationary parts of the frame gives AGILITY CMMs excellent strength and vibration-damping characteristics. The dynamic metrology elements, made of anodised aluminium, ensure accurate metrology across the full range of axis motion by eliminating differential expansion or bending.

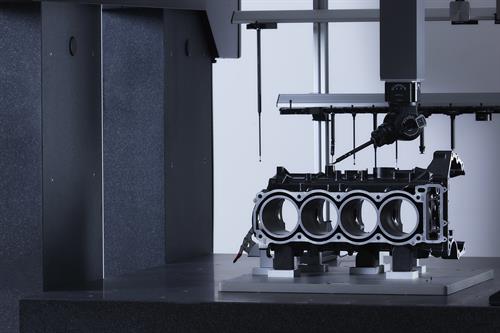

Optimised for REVO system performance

The REVO 5-axis multi-sensor system delivers high-performance scanning, non-contact inspection and surface finish analysis on a single CMM. Using synchronised motion and 5-axis measurement technology, REVO systems minimise the dynamic effects of CMM motion by doing the fast-demanding movements whilst the CMM moves smoothly and linearly.

The benefits of REVO 5-axis technology have been proven in a wide range of industries and applications, including automotive and aerospace.

REVO systems in powertrain manufacturing

By integrating automated roughness measurement and drastically reducing the number of styli required to measure complex parts, REVO systems have a direct impact on powertrain manufacturing effectiveness.

REVO systems in aerospace manufacturing

REVO is the global benchmark for the CMM inspection of aero engine, landing gear and airframe parts. Multi-sensor capability with high-speed data capture delivers significantly improved cycle times, unmatched feature access and reduced part handling.

Case studies and downloads

-

Application note: Faster cylinder head inspection

Application note: Faster cylinder head inspection

-

Application note: Faster cylinder head inspection

Application note: Faster cylinder head inspection

-

Case study: Escribano - Measuring with speed and precision

Case study: Escribano - Measuring with speed and precision

-

Case study: ANT Industries - "There is no other option to REVO, nothing else comes close"

Case study: ANT Industries - "There is no other option to REVO, nothing else comes close"

-

Case study: TURBOCAM "high fives" revolutionary five-axis measurement technology

Case study: TURBOCAM "high fives" revolutionary five-axis measurement technology

Contact our team of experts today

Get in contact with your local office to find out more information and speak to an expert.