Stran trenutno ni na voljo v vašem jeziku. Lahko si ogledate strojni prevod, ustvarjen s storitvijo Google Translate. Te storitve ne zagotavljamo mi in rezultatov prevoda nismo preverili.

Za dodatno pomoč se lahko obrnete na nas.

Optical encoders case studies and application notes

Our case studies and application notes for optical encoders showcase how our products can provide precision measurement solutions. See real-life examples of our customers using high quality Renishaw encoders across a variety of applications.

Optical encoders help our customers to achieve their potential in position measurement

Choose an industry to discover more

Industries trust Renishaw optical encoders to solve precision measurement challenges. Learn how the latest encoder technology has affected businesses in applications as varied as electronics, machinery, manufacturing, research, aerospace, and healthcare.Case studies - Electronics

ASMPT chooses Renishaw for high-quality motion control

ASMPT has introduced new products designed to meet growing demand for semiconductors due to emerging technologies. Renishaw, a long-standing metrology supplier, offers extensive experience in quality control, encoders and customised solutions. Encoder solutions include the ATOM DX™ miniature incremental encoder series, the VIONiC™ incremental encoder series, as well as the RESOLUTE™ absolute encoder series.

RESOLUTE™ absolute encoder supports ITRI breakthrough in multi-axis rotary table design

ITRI in Taiwan has developed an advanced dual-axis rotary table that integrates the RESOLUTE absolute rotary encoders, significantly enhancing accuracy and rotational speed for complex machining operations. This innovative design reduces build costs by over 50% compared to international brands and aims to transfer these technologies to local manufacturers to develop competitive rotary tables with high cost-performance.

Lasing Microsystem S.A. establish relationship with Renishaw as a solution provider for high accuracy and position checking applications

Lasing Microsystems S.A. is a leading source of technology for instrumentation and photonics products, focusing on lasers and precision positioning. Renishaw provided encoder solutions that delivered higher accuracy and position checking.

- Encoders accelerate PCB impedance verification

- Scodix chooses TONiC™ encoders for its Ultra™ series of digital enhancement printing presses

- ATOM™ encoders allow rapid, high-accuracy FPD inspection and repair

- Thorlabs selects TONiC™ encoders for its motion stages after in-house testing

- In ALIO's tiny world of nano-motion systems, Renishaw encoders provide large performance and cost advantages

- VAD Instrument chooses Renishaw's UHV optical encoders for motion platforms

- The world's No.1 semiconductor assembly & packaging equipment manufacturer benefits from Renishaw's innovative products

Case studies - Machine builders

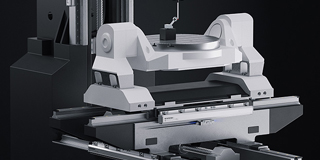

Enhancing micro-milling precision with FORTiS-N enclosed encoders

Anderson Europe chose FORTiS-N™ enclosed encoders to build state-of-the-art precision micro-milling machines. These linear encoders provide high accuracy, robustness, sealing against contamination and vibration resistance — ensuring outstanding performance in micro-milling applications.

Renishaw's enclosed encoders used in new hybrid additive and subtractive machine tool

To help Effective CNC design and build an 'all-in-one' machine that can perform both additive and subtractive machining operations in tandem, Renishaw provided support with its technical teams specialising in optical position encoders, tool setters and machine tool probes.

Improving machine tool accuracy with Renishaw FORTiS™ encoders and laser calibration systems

Renishaw's products help HEAKE machine tools to produce consistently high-quality parts. HEAKE LTD uses Renishaw's advanced metrology products to enhance machine tool accuracy and performance, such as the FORTiS™ enclosed linear encoder and the XK10 alignment laser system.

Case studies - Precision manufacturing

Ronchini Milling Technologies chooses Renishaw metrology products to enhance cutting-edge milling machines

RM Technologies has significantly improved the precision, reduced the set-up times, and enhanced the reliability of its milling machines by integrating Renishaw's advanced products. The products include the FORTiS™ enclosed position encoder, ADTa-100 diagnostic tool, RCS P-series probing system, and the QC20 ballbar.

R.A.M. Service retrofits a classic grinding machine with FORTiS™ linear encoder scales

R.A.M. Service, a specialist in retrofits and technical services, successfully upgraded an old Studer S30 grinding machine for Euro Tecno Tool by installing Renishaw's FORTiS linear encoder scales. These provide micron-level precision and easy installation, significantly improving the Studer machine's accuracy and ability to grind complex shapes.

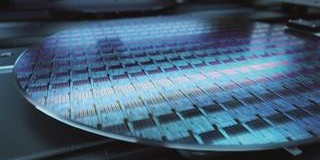

ONENG partners with Renishaw to build new advanced motion stages for semiconductor industry

Advanced motion stages are essential for high-performance equipment in semiconductor manufacturing. There is a growing demand for versatile motion stages in industrial automation and precision machining. To help meet this demand, ONENG, a South Korean motion stage producer, has worked with Renishaw to leverage its metrology and motion control expertise.

- Taking precision to new heights - air bearing stages with Renishaw optical encoders

- Renishaw's FORTiS enclosed encoder enhances grinding precision and performance for TGT

- Renishaw encoders drive improvements in the performance of direct-drive motors

- ATOM™ encoders help JUSTEK deliver custom motion control solutions that drive up profits

- Renishaw's optical encoders selected for 'unique' linear motor

- TONiC™ encoders are key for advanced precision measurement and control

- Precision position feedback for smart manufacturing

- Raising the bar on rotary table accuracy

- Renishaw encoders support the latest in DUKIN's CMM design

- SOLPOWER rotary tables turn on RESOLUTE™ encoders

- REVO-2 and the ATOM™ encoder

- TONiC™ optical encoders support the latest generation of CMMs from COORD-3

- Amicra - Reliable positioning without a reference run improves process reliability

- New state of the art air bearing gantry features Renishaw's high-performance incremental encoder

Case studies - Scientific, research and analysis

Renishaw distributor upgrades telescope for astronomy research

Wise Observatory chose to replace legacy encoders on the two positioning axes of the main one-metre-diameter Ritchey-Chrétien telescope with RESOLUTE™ encoders. This has greatly enhanced both its positioning accuracy and positional stability.

RESOLUTE™ encoders give focus to big science

French technology company IRELEC Alcen manufactures optomechanical and robotics systems for synchrotron facilities worldwide. Renishaw's position measurement products have helped IRELEC to push the boundaries of synchrotron science.

Instron® equips its new ElectroPuls™ linear-torsion tester with advanced Renishaw encoders

Instron has launched an advanced bi-axial variant of the ElectroPuls™ E3000 All-Electric test instrument. Renishaw's RESOLUTE™ is the only absolute optical encoder to support ElectroPuls controllers, while offering linear resolutions of 1 nm and speeds beyond 20 m/s.

Case studies - Aerospace

RESOLUTE encoders make RF antenna positioning accuracy and resolution one hundred times better

Pacific Antenna Systems (PAS) utilizes several different electro-mechanical designs for its antennas, depending on the application. Rotary position encoders are installed on each motion axis (gimbal) to provide the required precision and accuracy.

HAESL - incremental encoders help optimise the fuel efficiency of aero-engines

How fuel efficient is a commercial airliner? The honeycomb seal-ring has been proven to optimise the fuel efficiency of aero-engines, but the measurement of these seals present difficult engineering challenges. Now, HAESL has solved this challenge by incorporating Renishaw's TONiC incremental linear and rotary (angle) encoders within its new optical Seal Ring Measurement System (SRMS).

Case studies - Medical and healthcare

Renishaw encoders go under the 3DHISTECH microscope

3DHISTECH designs and manufactures one of the world's fastest and highest-capacity autonomous panoramic digital slide scanners - the P1000. It is a highly accurate scanning microscope that enables large pathology labs to capture ultra-high resolution images of medical samples. Renishaw's VIONiC™ and LA11 encoders enable the P1000 to operate at higher speeds than competing products in an accurate and repeatable way.

Application notes

The effect of heat on ballscrew accuracy in a CNC machine tool.

This application note discusses the impact of heat build-up in ballscrews on the accuracy of CNC machine tools. It uses test data to explain that while linear axis control with a semi-closed servo loop (using rotary encoders and ballscrews) can achieve high accuracy, thermal expansion of the ballscrew can cause significant error. Linear scales offer a crucial advantage in environments where heat build-up is a concern.

Selecting UHV-compatible encoders for demanding semiconductor and scientific applications

Processes like semiconductor manufacturing that demand precision motion control need vacuum-compatible optical encoders for position feedback. Locating the position encoders within the vacuum chamber ensures that the measurement device is as close to the working environment as possible, ultimately minimising errors.

FORTiS-S™ sealed linear encoders with lengths up to 4240 mm

Combining high-accuracy position measurement with robustness and reliability, the FORTiS™ enclosed linear absolute encoder series is designed to provide a solid foundation for CNC machining processes. Renishaw now offers FORTiS-S linear encoders in even longer measuring lengths, helping to bring these advantages to larger machines such as giga presses, vertical turning lathes and outsized CNC machine tools.

Reducing air purge usage with FORTiS™ encoders, achieving energy saving up to 91%

Machine users adopting a smart approach to air purge with FORTiS absolute enclosed encoders can significantly reduce their attributable CO2e emissions, and lower electricity costs. FORTiS' unique DuraSeal™ lip seals allow many users to employ a “low flow” air purge philosophy to provide all the reliability benefits of air purge but with reduced compressed air consumption.

Widening the scope for machine tool designers with the FORTiS enclosed encoder

The FORTiS enclosed encoder has been designed to cater for the needs of machine tool OEMs, end-users and service providers. Two new application notes talk directly to these important markets in describing the diverse features and benefits of the FORTiS encoder range.

- Floating steel encoder scales for SMT

- Substrate mastered encoder scale for laser cutting machine

- Laser micromachining: A role for Renishaw's VIONiC™ encoder

- Substrate mastered scale on a CMM

- Advanced position encoders in photolithography

- Solar powered - what links metrology with solar energy?

- Renishaw's new VIONiC™ encoder offers unparalleled performance

- Industrial control loops and how they apply to encoders

- Introducing the RESOLUTE™ FS encoder

- Optical encoders and LiDAR scanning

- Miniaturising innovation in the encoder business with the ATOM encoder

Next steps

Find the scale, readhead, interface and optional hardware suitable for your motion control solution. Discover our wide range of optical encoder systems. Create a part number and request relevant information.