Deze pagina is momenteel niet beschikbaar in uw taal. U kunt met behulp van Google Translate een automatische vertaling bekijken. Wij zijn niet verantwoordelijk voor deze dienstverlening en het vertaalresultaat is niet door ons gecontroleerd.

Heeft u meer hulp nodig, neemt u dan contact met ons op.

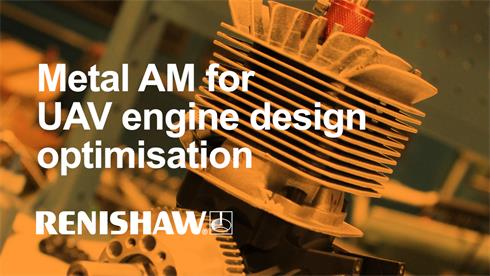

Metal additive manufacturing for UAV engine design optimisation

Case study video

Renishaw, worked with engine manufacturing company Cobra Aero to optimise its design processes for aircraft and motorcycle engines. After working with Renishaw to develop new manufacturing processes, Cobra Aero invested in the AM 400 system to increase its additive manufacturing (AM) capabilities.

To optimise the design of its engine cylinders for motorcycles and aircrafts, Cobra Aero worked with Renishaw to gain expertise in AM. The company visited a Renishaw Additive Manufacturing Solutions Centre and collaborated with Renishaw engineers to use AM to improve the design of a cylinder for an unmanned aerial vehicle (UAV).

Using AM technology allowed Cobra Aero to design a lattice structure to increase airflow easily and also allowed them to produce one solid, lightweight part.