Productie van elektrische voertuigen

De toekomst van EV-productie

Van snel bewerkte gietstukken scannen met meerdere sensoren tot materiaalanalyse van brandstofcellen, wij ondersteunen onze klanten in de autoproductie op hun weg van inwendige verbrandingsmotoren (IVM's) naar elektrische voertuigen (EV's).

Uw partner voor innovatie

De toegenomen productie van voertuigen op nieuwe soorten energie, waaronder hybrides en volledige EV's, heeft flinke verschuivingen gebracht in de autotechniek en autoproductie. Aangezien de technologie voortdurend wordt verfijnd, is flexibele en aanpasbare productie fundamenteel voor commercieel succes op weg naar EV's.

Met ondersteuning voor productie- en inspectieprocessen die slim genoeg zijn om procesverloop te corrigeren en flexibel genoeg om met vele ontwerpiteraties om te gaan, kunnen wij u helpen om uw productie vlot aan te passen voor deze elektrische toekomst.

Accu's voor auto's

- Basismaterialen analyseren

- Prestatiebereik onderzoeken

- Leveringsketen controleren

Met onze niet-destructieve Raman technologieën kunt u de accuchemie onderzoeken onder een reeks van bedrijfsomstandigheden, zoals snelladen en extreme temperaturen. Bekijk hoe een accu reageert en overweeg hoe zijn efficiëntie te verbeteren is.

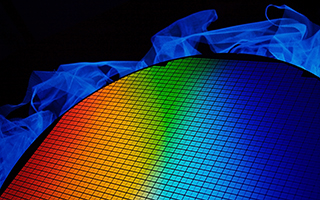

Vermogenselektronica

- Materialen niet-destructief inspecteren

- Kwaliteit en materiaalopbrengst verbeteren

- Storingen in het veld verminderen

Nieuwe halfgeleidermaterialen bieden hogere maximale vermogens en efficiëntie bij kleinere afmetingen en gewichten. Met behulp van onze Raman technologieën kunt u deze lastig te verwerken halfgeleidermaterialen doorgronden en betere apparaten ontwikkelen.

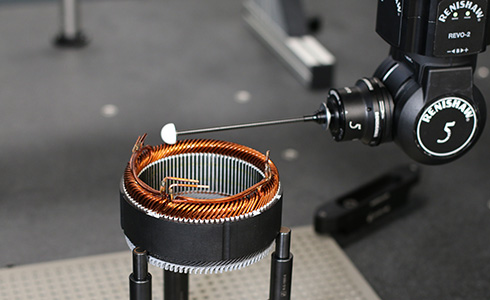

Elektromotoren

- Kophoogte controleren op goedkeur/afkeur

- Isolatiepapier controleren

- Snel stators inspecteren met REVO

Voorkom dat verkeerde componenten waardevolle eindproducten tot uitval maken. Ons Equator™ in-lijn meetsysteem kan snel vormkenmerken inspecteren van het samengestelde blikpakket van een stator. Als een ontwerp verandert, is het Equator systeem eenvoudig te herprogrammeren.

Trillingreductie bij versnellingsbakken

- Productieproces controleren in gesloten kringloop

- In-lijn meten op de productielocatie en meetsystemen met meerdere sensoren

- Ontwerpen en inspectieprocessen snel en flexibel aanpassen

Door de toleranties van componenten te controleren kunnen fabrikanten nauwkeurigere tandwielen en stevigere behuizingen produceren om het trillingsniveau van versnellingsbakken te reduceren en de voertuigefficiëntie te verbeteren.

Motoren

- Oppervlakteafwerking meten

- Klepzittingen en -geleiders 5-assig scannen met REVO, ook met meerdere sensoren voor contactloze inspectie

- Oppervlaktetoestand en vorm snel meten op de machine voor procescontrole

Hybride voertuigen moeten elke druppel rendement uit de verbrandingsmotor persen. Het motorrendement is gevoelig voor kleine productievariaties in en om de gebieden van klepzittingen en klepgeleiders in de cilinderkop. Controleer klepzittingen en -geleiders en verbrandingskamers met de REVO® 5-assige scantechnologieën.

Autotechniek op weg van IVM naar EV

Gareth Tomkinson, automotive business development manager bij Renishaw, legt uit hoe productie-oplossingen van Renishaw de snelheid, de flexibiliteit en het gebruiksgemak leveren die u helpen om uw productie aan te passen voor deze elektrische toekomst.