Por el momento, esta página no está disponible en español. Puede obtener una traducción automática mediante la opción de traducción de Google.

No podemos responsabilizarnos de este servicio puesto que podemos no verificar los resultados de la traducción.

Si desea más información, póngase en contacto con nosotros.

Develop battery materials with Raman spectroscopy

Determination and distribution of structure

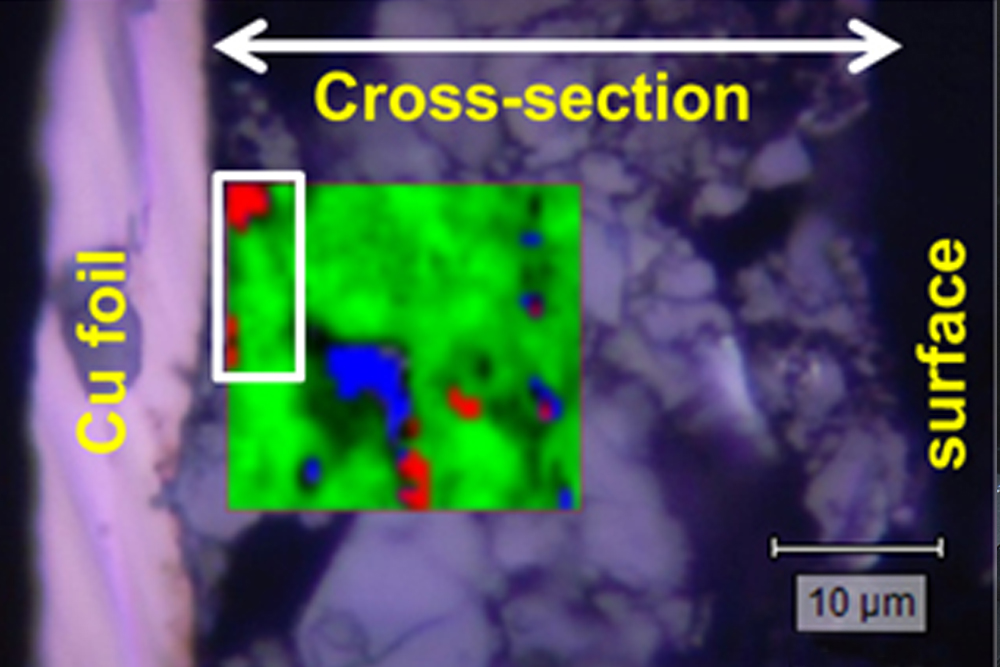

Raman mapping and imaging enables the study of the distribution of materials on electrode surfaces, or across cross-sections. The resulting data can be quantified, giving metrics such as fraction estimates and particle statistics.

Identification of materials

inVia can analyse all the key material types: organic and inorganic; crystalline and amorphous; solids, liquids, and gases. Its high sensitivity makes identifying all the key battery components easy: carbon materials, metal oxides, polymers, electrolytes.

In situ measurements

Use inVia with a wide range of sample chambers, electrochemical cells and inert gas glove boxes. Raman data acquisition on inVia can also be triggered from devices such as potentiostats, enabling in situ and operando measurements.

The benefits of spectroscopy

- Getting data, without damage: Lithium-ion battery components can be altered or damaged by high laser power densities. With Renishaw's line-focus laser illumination technology, power densities are reduced but total laser power is retained, so you can collect high quality data rapidly, and with confidence.

- Sensitivity: inVia's high sensitivity and high spatial resolution enable you to detect materials even if they are present in low concentrations, such as binders.

- Correlated information: Combine inVia with an atomic force microscope and get not only chemical information from Raman spectroscopy, but also correlated surface topography information from AFM.

- Solve your lithium-ion battery problems: Contact us and find out more about how an inVia Raman microscope can help you.

Supporting electric vehicle battery range performance research

Automotive R&D is increasingly focused on new propulsion technologies for the next generation of hybrid and electric vehicles (EV). At the heart of EV product development is the pursuit of extended range through motor efficiency and battery effectiveness.

Our Raman technologies offer a non-destructive method of monitoring and imaging battery chemistry so that the most suitable materials can be developed and their performance limits understood. Our inVia™ confocal Raman microscope, for example, enables automotive battery manufacturers to examine battery chemistry under a range of operating conditions (such as fast-charging and extremes of temperature) to see how the battery reacts and work out how to improve its efficiency.

Key areas of EV battery research

- Range: increasing power density gives greater range between charges, in line with consumer requirements.

- Fast charging: designs that allow more efficient charging increase usability and market adoption.

- Production: more efficient production methods can help to reduce manufacturing costs.

- Chemistry: new chemistries can help to reduce reliance on rare earth materials and lower costs.

- Quality control: methods of verifying materials and component structure to improve performance.

On-demand webinar: Solving challenges in green energy research

In this webinar we show how you can characterise novel materials with Raman spectroscopy. Examples include lithium-ion batteries, LEDs, poly-crystalline silicon and perovskite solar cells.

Watch the webinar

We're here when you need us

To find out more about this application area, or an application that isn't covered here, contact our applications team.

Contact our applications team