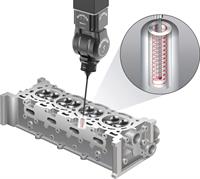

REVO valve seat and guide measurement

REVO® and Renishaw's 5-axis technology dramatically increase throughput in this challenging application – data collection process takes approximately 20 seconds.

The measurement of valve seat and guides has traditionally been very challenging, involving time-consuming methods that often do not provide a sufficiently capable measurement.

REVO overcomes that challenge; collecting large amounts of data, from which the analysis parameters for both valve seat and the valve guide features can be calculated, can be done very quickly now. The method performs exceptionally well in repeatability and reproducibility tests.

Helical scans

The measurement process involves two helical scans, one on the valve guide bore and the second over the valve seat area. On the guide a single helical scan is used with a typical pitch of 0.5 mm, at a scanning speed of 150 mm/s.

Adaptive scanning

This valve seat scan uses REVO's adaptive scanning capability, which allows a single scan command to cover the areas above and below the critical valve seat surfaces. On the valve seat a single helical scan is used, with a typical pitch of 0.1 mm, at a scanning speed of 500 mm/s.

Data evaluation

The valve seat and guide analysis utility that is embedded in Renishaw's MODUS metrology software is used to evaluate the scan data and return the attributes listed below:

- Form error of the valve seat

- Circularity profile of the seat at any specified height

- Valve seat width

- Runout of the seat to the guide bore axis

- Diameter of the guide

- Straightness of the guide cylinder

- Cylindricity of the guide

- Circularity profile of the guide cylinder at any specified height

- Form errors of the cones, above and below the valve seat cone

Please note that Renishaw provides this analysis facility to other metrology software providers that support the REVO system.