Metrology fixtures for CMM and gauging

Metrology fixtures for co-ordinate measuring machines (CMMs) and Equator™ gauging can improve the throughput, reproducibility and accuracy of your inspection process by providing quick and repeatable fixturing set-ups for your components.

CMM and Equator™ gauging fixturing

Secure parts prior to measurement using our modular CMM and gauging fixtures

CMM fixtures

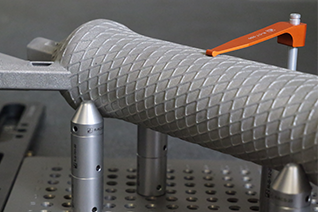

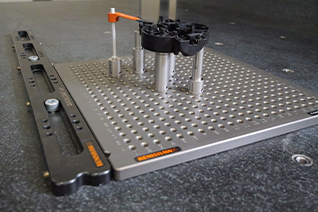

Our components allow you to fixture workpieces of almost any size, shape or material onto your measuring bed. Our wide range of metrology fixtures for CMMs and Equator gauging, includes a choice of standard size base plates and an extensive selection of components with M4, M6, M8 or 1/4-20 threaded fittings.

Whether you are inspecting workpieces for aerospace, automotive, electronics, industrial or medical applications, Renishaw can provide a complete fixturing solution for any workpiece regardless of its size, shape or material.

How to order

Use our Online store to order 24/7. Shop online and benefit from quick delivery of our modular CMM and gauging fixturing range.

Maximise inspection throughput whilst maintaining flexibility

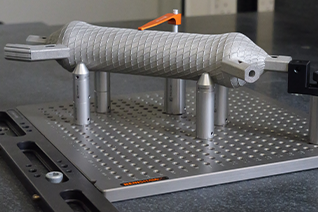

To minimise unproductive set-up time, whilst maintaining fixturing flexibility, workpieces can be fixtured on a base plate away from the CMM, vision machine or Equator gauging system. The fixtured workpiece can be loaded onto the inspection device with ease, immediately prior to measurement.

Filling the measurement area of a CMM with multiple fixtured parts is another way to minimise set-up time. Multiple workpieces on the CMM bed can be measured in one batch, without the need to start and stop the measurement cycle to load more fixtured workpieces.

A large range of components

Our modular CMM fixtures can be used to secure parts of almost any size, shape or material. Base plates and components are available as standard in M4, M6, M8 metric and 1/4-20 imperial thread sizes.

With a range of fixturing solutions available in our Online store, your fixture collection can be expanded when your requirements change.

Reproducible set-ups

Identical fixturing set-ups are important to ensure the repeatability of inspection by removing variation from the process. Set-ups can be accurately documented and reproduced using our alpha-numerically labelled base plates and labelled fixturing components.

Fast assembly

Fixturing solutions can be assembled very quickly to increase throughput and avoid delays in inspection. All components are hand-tightened and require no special tools.

Unrivalled wear resistance

Our heat treated steel components and hard coated base plates, provide a smooth and scratch resistant finish.

Remember our modular and custom fixturing can improve the throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups. Renishaw fixtures can provide a complete solution to your fixturing requirements.

Enhanced fixturing sets

Discover four brand new sets designed to suit more applications, giving you the user more flexibility.

Metrology fixtures for AGILITY® CMM systems

Maximise your productivity with fixture plates for AGILITY CMM systems

Maximise working volume

Our specially designed fixture plates cover the CMM bed and bolt straight onto it for more stable and accurate measurements. Allowing you to fixture large components that might utilise the entire working envelope of the machine.

Hard coat black anodized

Our cast aluminium base plates are hard coat anodized in black to resist wear and scratching.

Secure parts of any size, shape, or material

Our modular CMM fixtures can secure parts of almost any size, shape, or material, and can be expanded as your requirements change.

Modular fixturing solutions:

Reduce set-up time

Need a system to easily swap out smaller fixtures? The QuickLoad™ rail can be located and secured to the left, right, or centre of the CMM granite, or to an existing modular base plate, allowing you to fill the CMM bed with fixtured workpieces, reducing set-up time and increasing CMM productivity.

Design and document configurations

Our 3D-modelling software, FixtureBuilder, can be used to design and document QuickLoad rail configurations and modular fixturing set-ups, making configurations easy to reproduce.

Improve reproducibility and accuracy

By using Renishaw fixtures on the base plates of the AGILITY CMM, you can improve the reproducibility and accuracy of your inspection process.

-

Data sheet: Metrology fixturing plates for AGILITY® CMM systems

Data sheet: Metrology fixturing plates for AGILITY® CMM systems

Renishaw’s fixturing base plates provide a platform to begin construction of fixtures on your AGILITY® CMM. Designed to allow for the use of the full measurement volume they are mount directly to the bed using the M10 threaded inserts.

[358kB]

QuickLoad™ rail systems for CMMs

Renishaw QuickLoad rail system increases CMM inspection throughput, reduces set-up time and improves repeatability. Our modular and custom fixturing can improve the throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups.

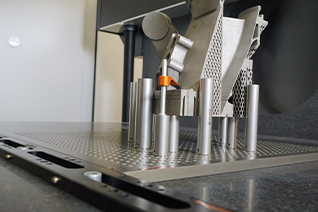

The QuickLoad rail system makes loading and unloading fixtured workpieces onto your CMM quick and easy. Multiple plates can be loaded to either side of the QuickLoad rail, allowing you to make use of all of the space on your CMM bed.

Load parts quickly

Use QuickLoad rail to reduce the time spent securing fixtured workpieces to the CMM bed. Specially designed QuickLoad base plates locate to the QuickLoad rail, on either side, using quick release magnets and location pins. This design allows plates to be loaded and unloaded swiftly, reducing unproductive set-up time and maximising productivity.

Fill the CMM bed

QuickLoad rail can be located and secured to the left, right or centre of the CMM granite, or to an existing modular base plate. As multiple plates in many configurations can be loaded to one or both sides of the QuickLoad rail, it is possible to fill the CMM bed with fixtured workpieces. Maximising the measurement volume in this way reduces set-up time and increases CMM productivity.

Alpha-numeric labels

Recording the fixture set-up is simple as each QuickLoad base plate has an alphanumeric grid pattern, and each fixturing component has a clearly labelled part number.

FixtureBuilder compatibility

FixtureBuilder software can be used to design and document QuickLoad rail configurations and modular fixturing set-ups. Build instructions make configurations easy to reproduce.

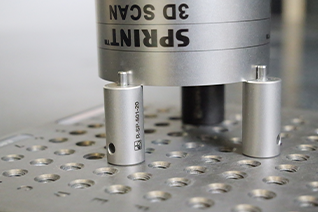

Modular fixturing components

Renishaw's modular fixturing ranges can be used with the QuickLoad rail system. A wide variety of fixturing components are available in M4, M6, M8 and 1/4-20 thread sizes from the Online store.

Robust base plates

The QuickLoad rail system benefits from Renishaw's industry leading hard-coat anodised, aluminium QuickLoad™ base plates, which are available in M6 thread size, with M4, M8 and 1/4-20 options available upon request.

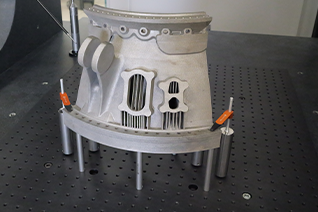

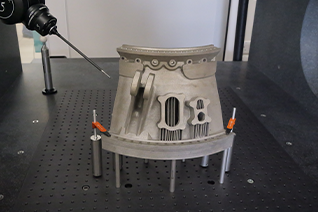

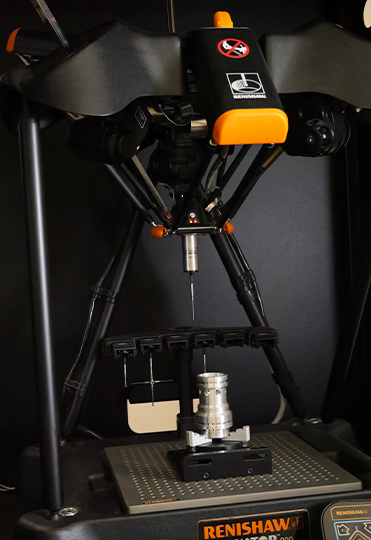

Metrology fixtures for Equator™ gauging

Our Equator fixtures have specifically designed base plates with a 3-point kinematic system allowing for quick loading and unloading on to the machine. The positive engagement of the base plate ensures each fixture is repeatedly located and securely held in place, allowing quick changeover of parts on and off the Equator within seconds.

Using Renishaw Equator fixtures can improve the throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups that are easy to configure:

Base plates are alpha-numerically labelled so set-ups can be documented and repeated quickly and accurately.

All components are hand-tightened and require no special tools.

Fixturing components can be easily positioned for minimal contact on and around the part, providing an unobstructed probe path for inspecting every detail on the part.

Base plates are available in M4, M6, M8 or 1/4-20 thread sizes and made from cast aluminium coated with hard coat anodise to reduce wear and scratching.

For any custom Equator fixturing requests, please submit one of the custom forms below or contact your local sales office.

Online store

Visit the Renishaw Online store to order your QuickLoad™ rail or Equator fixtures.