InfiniAM Central

InfiniAM Central enables near real-time insight into your live AM builds and access to analyse historic builds.

System sensor and build information is displayed in graphic form to enable intuitive in depth analysis.

Key benefits

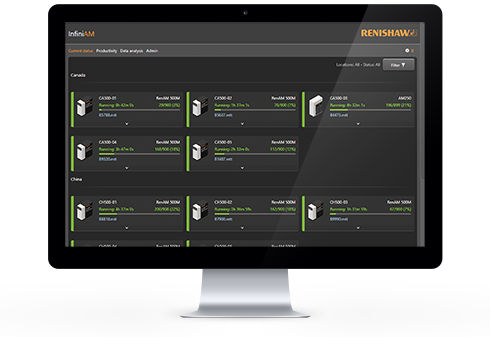

Current status

From the Current Status page, users have visibility of all the resources within their AM facility or group. System status (such as running, cooling, idle, etc), details of the part being built, layer-by-layer progress, powder level and system alarms are shown.

Productivity

The Productivity page displays the usage time for each AM system, it displays running, stopped and cooling times. This enables users with an interest in the Overall Equipment Efficiency (OEE) to see where there are opportunities to improve manufacturing efficiency.

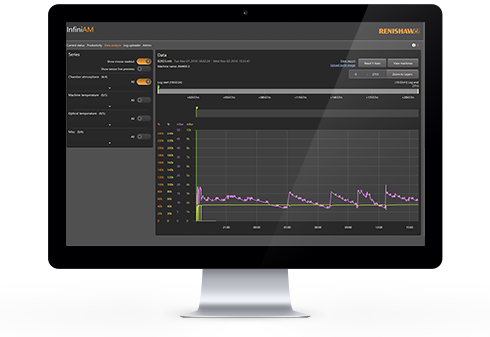

Data analysis

The Data Analysis page enables users to view live information from the AM system on the production line. Individual sensors have defined thresholds, limits or setpoints, and provide a detailed visual insight into AM system performance. Reports can be generated post-build to provide a detailed summary of build events.

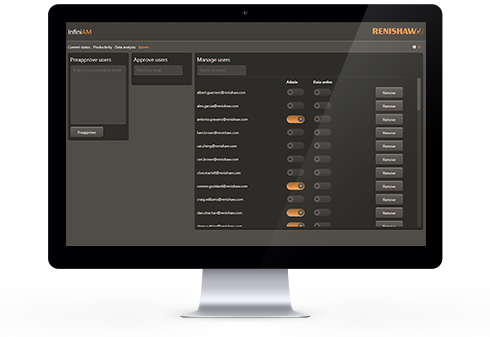

Security

The Admin page enables administrators to manage all user permissions. The system can be integrated with your company's network logins via Lightweight Directory Access Protocol (LDAP) compatibility.

Get mobile notifications via the smartphone app

Available for iOS and Android, the InfiniAM Central app provides push notifications of system alarms, current status and current build details including powder level, layer-by-layer build progress and event history. Systems can be monitored remotely and notifications* sent in near real-time**.

* push notifications require a limited set of information to be passed through Renishaw servers in order to send messages via Apple's notification service or Google's Firebase service.

** actual time depends on network latency and smartphone connectivity.

Download

-

Brochure: InfiniAM Central – remote process monitoring for AM systems

Brochure: InfiniAM Central – remote process monitoring for AM systems

InfiniAM Central is Renishaw’s process monitoring software solution. It enables live process monitoring and build data recording for your Renishaw AM systems. Build data forms an essential part of a quality management system to ensure consistent and repeatable AM production.

[1.1MB]