Our history

Over 50 years of innovation

At Renishaw, we have spent over 50 years engineering change. Our company was established in 1973 by the late David McMurtry (later Sir David McMurtry), and John Deer, Non-executive Director. Renishaw's first product, the touch-trigger probe, was invented by Sir David to solve a specific inspection requirement for the Olympus engines used in Concorde. This innovative product led to a revolution in three-dimensional co-ordinate measurement, enabling the accurate measurement of machined components and finished assemblies.

Throughout our history we have made a significant commitment to research and development with typically around 13% to 18% of annual sales invested in R&D and engineering. This has enabled us to design, develop and deliver solutions that provide unparalleled precision, control and reliability.

Our commitment to investments in people, product development and production capacity, are all underpinned by a commitment to be a more sustainable organisation, to ensure we continue transforming tomorrow together.

1970s

1972 - David McMurtry invents first touch-trigger probe

1973 - Renishaw Electrical Ltd registered and first probe for CMMs (TP1) made commercially available

1976 - First commercial premises, a former ice cream factory in Wotton-under-Edge, UK

1977 - First dedicated probe for machine tools - enabling automated setting and inspection

1979 - Start of the Early Careers programme with the first apprentices employed (sponsored student scheme started 1984)

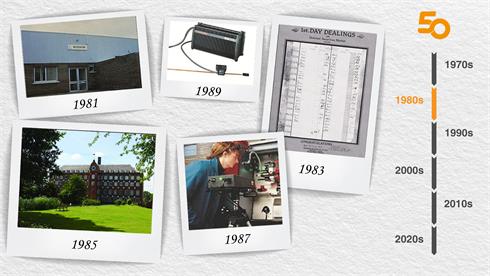

1980s

1981 - International expansion with a manufacturing facility in Ireland and the first sales subsidiary, Renishaw Inc, established in Chicago, USA

1983 - Flotation on the London Stock Exchange's Unlisted Securities Market (full listing in 1984)

1985 - New Mills site in Gloucestershire, UK (now the Company's headquarters) officially opened (site purchased 1981)

1987 - First laser interferometer system – transforming the speed and accuracy of machine calibration

1989 - Introduction of the first range of encoder readheads and interfaces

1990s

1991 - QC10 ballbar system - enabling rapid analysis of machine tool positioning performance

1991 - Raman microscope introduced to provide detailed chemical and structural characterisation

1992 - Introduction of RAMTIC (Renishaw's Automated Milling, Turning and Inspection Centre) an in-house system still in use for component production

1995 - First laser scale system

1997 - 1,000 employees worldwide

2000s

2000 - Worldwide sales reach £100 million

2001 - David McMurtry receives knighthood ‘for services to design and innovation'

2003 - Largest international expansion in one year with office openings in Austria, Canada, Hungary, Israel and Sweden

2005 - Launch of the REVO® five-axis measurement system, enabling a 10x increase in tactile measurement speeds

2007 - Neurological product line established

2010s

2011 - Gauging and additive manufacturing product lines introduced

2011 - Miskin manufacturing site purchased in South Wales

2013 - Metrology fixtures product line introduced

2018 - Launch of the RenAM 500Q four-laser additive manufacturing system

2019 - 5,000 employees worldwide

2020s

2020 - Helped deliver over 13,000 ventilators to the UK's National Health Service during Coronavirus (COVID-19) pandemic

2021 - Record year for UK graduate and apprentice opportunities - 96 graduates and 80 apprentices

2021 - Launch of the FORTiS™ range of next-generation enclosed linear absolute encoders

2022 - Announce detailed Net Zero emissions commitments

2022 - £65 million expansion begins at Miskin manufacturing site in South Wales

Downloads

-

Flyer: 50 years of manufacturing innovation

Flyer: 50 years of manufacturing innovation

A special anniversary magazine charting the history of global manufacturing technologies over the last five decades and the impact that our own engineering innovations have had on the business of making things.