AxiSet™ Check-Up

Fast, automated health checks for multi‑axis machine tools.

AxiSet™ Check-Up is a cost-effective solution for checking and improving rotary axis performance

AxiSet Check-Up offers an easy and reliable process for analysing the performance of rotary axes and for identifying problems caused by incorrect machine set-up, collisions or wear. In just a few minutes, users of multi-axis machining centres and multi-tasking machines can identify poor machine alignment, geometry and pivot point errors that can cause extended process setting times and non-conforming parts. Where possible, AxiSet Check-Up automatically corrects on-machine pivot point parameters.

Reduce scrap, enhance productivity and increase profits – Renishaw machine tool probes can keep your machining process under control.

Data analysis made simple

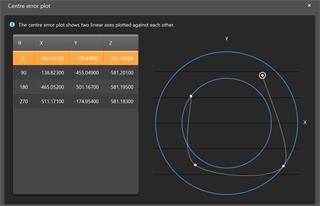

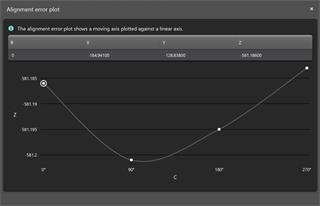

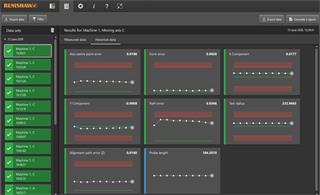

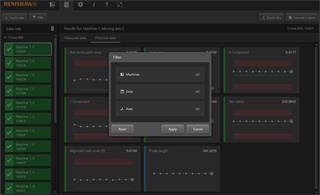

The AxiSet Check-Up app graphically displays the measurement data produced by the AxiSet Check-Up macro software.

The app provides graphical representations of multi-axis machine performance data that can help to make PASS or FAIL decisions based on defined tolerances. Machine performance can be tracked over time, using the app's historical data chart function.

System components

Macros

Written for a range of CNC controllers, AxiSet Check-Up probing macros are machine specific and available for machining centres and multi-tasking machines. These macros drive the machine, collecting measurement data.

They also offer the option to automatically update parameters and compensate for rotary axis pivot point errors.

App

The AxiSet Check-Up app provides a detailed and graphical representation of the measurement data produced by the macro software.

The app is installed onto a PC or tablet running Windows 10 (32 or 64 bit) or above and must be licensed before it can be used. Perpetual and evaluation licences are available.

Hardware

A single calibration sphere, conveniently mounted on a magnetic base, is used as a reference feature for measurements.

This simple-to-use artefact ensures that set-up time is kept to a minimum and, in most cases, does not require fixtures or parts to be removed.

We recommend that customers use AxiSet Check-Up to test the machines' rotary axes after they are installed, as factory conditions may differ significantly from Hartford's manufacturing conditions, in terms of foundations and how level surfaces are. Shipping and installation can also cause precision errors, so AxiSet Check-Up automatic compensation allows machine tools to maintain high levels of precision and quality.

Hartford (Taiwan)

Recommendations

RENGAGE™ technology – For the optimum performance, Renishaw's high-accuracy machine tool probes with RENGAGE technology are recommended.

Calibrated test bar – Ensures that AxiSet Check-Up measurements are traceable and comparable to the settings made by machine tool builders.

Next steps

Contact your local sales representative if you think AxiSet™ Check-Up is right for you.