Additive manufacturing customer case study videos

A collection of case study videos showcasing how our customers use their additive manufacturing systems and the applications in which they are applied:

-

INEOS TEAM UK innovates structural components with additive manufacturing

INEOS TEAM UK innovates structural components with additive manufacturing

Case study video featuring INEOS TEAM UK T5 Mast Ball. The mast ball transmits power from the rig into the foiling hull and was built lighter and stronger by Renishaw using its AM technology. Renishaw is INEOS TEAM UK’s official precision measurement and additive manufacturing partner and has helped the team to optimise the design and manufacture of parts, such as the mast step, a structural component for the team's test boat.

[1920 x 1080] [462.2MB]

-

Brunel University race ahead with additive manufacturing

Brunel University race ahead with additive manufacturing

Global engineering technologies company, Renishaw, is supporting the Brunel University London race team in its 20th year participating in the Formula Student (FS) competition. Renishaw is contributing its metal additive manufacturing (AM) expertise to help Brunel Racing create a manifold part for the team’s BR-XX car, which will be used to compete at FS-UK in Silverstone and FS-ATA in Italy in July.

[1920 x 1080] [418.0MB] -

Atherton Bikes accelerates with additive manufacturing

Atherton Bikes accelerates with additive manufacturing

Global engineering company Renishaw is working with new mountain bike brand Atherton Bikes to produce additively manufactured titanium lugs for the company's bike frames. The new brand was launched in January by the Atherton siblings, Gee, Rachel and Dan and co-founded by Piers Linney of Dragons' Den fame. The introductory bike range will be manufactured from carbon fibre tubing and lugs produced on a Renishaw multi-laser high productivity RenAM 500Q metal additive manufacturing (AM) system.

[1920 x 1080] [437.2MB]

-

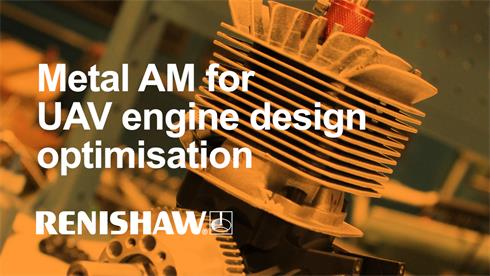

Metal additive manufacturing for UAV engine design optimisation

Metal additive manufacturing for UAV engine design optimisation

Renishaw, worked with engine manufacturing company Cobra Aero to optimise its design processes for aircraft and motorcycle engines. After working with Renishaw to develop new manufacturing processes, Cobra Aero invested in the AM 400 system to increase its additive manufacturing (AM) capabilities.

[1920 x 1080] [227.8MB] -

Cobra demonstrates additively manufactured UAV engine

Cobra demonstrates additively manufactured UAV engine

To optimise the design of its engine cylinders for motorcycles and aircrafts, Cobra Aero worked with Renishaw to gain expertise in AM. The company visited a Renishaw Additive Manufacturing Solutions Centre and collaborated with Renishaw engineers to use AM to improve the design of a cylinder for an unmanned aerial vehicle (UAV). Using AM technology allowed Cobra Aero to design a lattice structure to increase airflow easily and also allowed them to produce one solid, lightweight part.

[1920 x 1080] [223.6MB]

-

Optimising the design of direct drive valves through metal AM

Optimising the design of direct drive valves through metal AM

Global engineering technologies company, Renishaw, recently collaborated with Domin Fluid Power to help the company maximise productivity when designing and manufacturing direct drive valves. Using metal additive manufacturing (AM) techniques, the company can now manufacture smaller, more efficient drives and reduce cycle times from five and a half hours to just one. Domin collaborated with Renishaw to develop a new, stable, state-of-the-art technology suite for the fluid power sector. The company visited Renishaw's AM Solutions Centre in Stone, Staffordshire, UK, to develop their understanding of AM and understand how the technology could help them to produce highly efficient drives for customers.

[1920 x 1080] [160.7MB] -

Streamlining additive manufacturing for spinal implants

Streamlining additive manufacturing for spinal implants

Global engineering company, Renishaw, collaborated with two innovative technology companies to demonstrate the capability of metal additive manufacturing (AM) technology to produce lightweight titanium spinal implants that mimic the mechanical properties of bone.

[1920 x 1080] [59.5MB]

-

Additive manufacturing in the oil and gas industry - A case study

Additive manufacturing in the oil and gas industry - A case study

Knust-Godwin is a precision machining company located in Katy, Texas. It specializes in large, complex parts for oil field instrumentation. Watch the case study video to find out more about Knust-Godwins expanding AM capacity to handle not only research and development, but serial production as well.

[1920 x 1080] [217.5MB] -

Powering the future of metal additive manufacturing at Sandvik

Powering the future of metal additive manufacturing at Sandvik

To strengthen the metal additive manufacturing (AM) industry, global engineering company Renishaw has collaborated with Sandvik Additive Manufacturing to supply the company with high productivity multi-laser RenAM 500Q systems, which will substantially increase Sandvik's printing capacity. Working with ongoing support from Renishaw, the investment will complement Sandvik's existing printing technologies and strengthen its position in the growing additive manufacturing market. The two companies also intend to collaborate in areas like materials development, AM process technologies and post-processing

[1920 x 1080] [314.9MB]

-

3D Metalforge ventures out into metal additive manufacturing

3D Metalforge ventures out into metal additive manufacturing

3D Metalforge uses Renishaw's additive manufacturing systems and software to help select a future-proof additive manufacturing system for flexible, high-quality end-use part production.

[1920 x 1080] [333.8MB] -

Additively manufacturing titanium watch straps

Additively manufacturing titanium watch straps

Uniform Wares partner with Betatype to explore the advantages of additive manufacturing (3D printing) technology, pushing the boundaries of an industry centred around heritage. The results of which led to the production of a superior quality additively manufactured titanium watch strap for their 2019 collection. Working closely to developing a mesh strap stronger and lighter than ever before, whilst overcoming time limitations faced by more traditional methods.

[1920 x 1080] [212.8MB]

-

Additively manufacturing the world's fastest velocipede

Additively manufacturing the world's fastest velocipede

Find out how a group of Engineering students at the University of Liverpool have been using metal additive manufacturing to help build a hand cycle in an attempt to break the land speed record at Battle Mountain in Nevada, USA.

[1920 x 1080] [295.3MB] -

Metal AM for aircraft assembly

Metal AM for aircraft assembly

Frazer Nash demonstrate a revolutionary way of speeding up the assembly of aircraft using metal additive manufacturing.

[1920 x 1080] [281.3MB]

-

TransFIORmers Moto2™ team benefit from metal a 3D printing technology

TransFIORmers Moto2™ team benefit from metal a 3D printing technology

Race winning Moto2 team TransFIORmers is using cutting edge additive manufacturing (metal 3D printing) technology in an unconventional front suspension system to gain a significant competitive advantage.

[1920 x 1080] [418.9MB] -

Mission to Nepal

Mission to Nepal

A young mother received ground-breaking surgery at the expert hands of consultant Oral and Maxillofacial surgeon Shakir Mustafa during an aid and education mission visit to Nepal. See how pre-planned processes created a perfectly fitting implant with excellent surgical results.

[1920 x 1080] [492.8MB]

-

Race to innovate: digital position feedback for Land Rover BAR

Race to innovate: digital position feedback for Land Rover BAR

Discover how Technical Leader Dr. Finlay Evans and his team raced to innovate special digital position sensors (encoders) for the Land Rover BAR race yacht. The solution enables the helmsman and crew to race the yacht with precise wing and rudder feedback whilst enabling the capture of high-quality performance data during development and training.

[1920 x 1080] [265.1MB] -

Making time for Holthinrichs Watches

Making time for Holthinrichs Watches

Michiel Holthinrichs, the founder of Holthinrichs Watches, is working with a Renishaw Additive Manufacturing Solutions Centre to build up his knowledge about the potential of metal additive manufacturing (AM) and to speed up the overall manufacturing process for his high-end, limited edition watches. His first design ‘Ornament 1’ combines traditional watchmaking elements, including a Swiss movement with manual winding and a design inspired by classic watches of the 1950s, with the new technology of metal 3D printing, which was used to produce the case, crown and buckle.

[1920 x 1080] [506.3MB]