High-accuracy touch probes for CNC machines

For unbeatable measurement performance, our high-accuracy touch probes for CNC machines offer the best possible in-cycle process controls. With ultra-low trigger forces and excellent repeatability, part setting and inspection can be performed with optimal results.

High-accuracy probing for peak performance

Engineered for over a decade, our high-accuracy touch probes deliver unparalleled performance and capabilities.

Suitable for a wide range of applications, our high-accuracy probes automate in-cycle setting and inspecting of workpieces, for fast and highly accurate machined parts.

Renishaw high-accuracy probes deliver superior measurement performance by utilising advanced probing mechanisms, with either RENGAGE™ technology or micro-kinematics. These technologies enhance and ensure first-time-pass machining of parts, including complex components with soft, flexible and intricate 3D shapes.

Constructed from high-grade materials, Renishaw machine tool probes are robust and reliable. They can withstand even the harshest environments, including shock, vibration, extreme temperatures, and continual liquid immersion.

Why use a probe?

Probing is essential when ensuring precision throughout machining processes. As a manufacturer, maintaining consistent product quality and maximising output is vital. That is why implementing quality control processes such as probing are incredibly beneficial.

Whether there is a need to streamline production by automating part setup and inspection, reduce machining errors, or a desire to reduce waste. Probing not only saves time and scrappage costs, it also boosts productivity by minimising downtime with automated tooling offsets and faster job setup. These benefits make each probe a great investment with rapid payback, enabling manufacturers to focus on quality, productivity, and profitability.

Key benefits of high-accuracy probes

Ultra-low trigger force

Eliminate surface and form damage when inspecting delicate workpieces.

Superior 3D accuracy

Unrivalled, submicron performance even when measuring complex 3D shapes and contours.

Robustly engineered

Providing reliable measurement and long service life, even in the harshest environments.

Precision measurement

Easily adhere to the tightest machining tolerances, first time and every time.

We are happy with the accuracy of the RMP600 and the consequent reduction in scrap parts further down the production line. These are large, expensive components and we can use the probe to identify and avoid errors.

Flann Microwave (UK)

Find the perfect high-accuracy touch probe for your manufacturing operations

Explore our range of high-accuracy probes, whether you need radio, optical, or hard-wired transmission. Each probe is designed for precision and ease of use in various manufacturing settings, and is compatible with machine tool probing software.

High-accuracy radio transmission probes

Radio transmission probes are ideal in complex or larger machines and installations, where the spindle probe is not within line-of-sight of the receiver.

In environments with high-density radio frequency (RF) traffic, Renishaw radio probes use patented FHSS (Frequency-hopping spread spectrum) technology, enabling the probe to jump from channel to channel – avoiding interference and transmission dead spots.

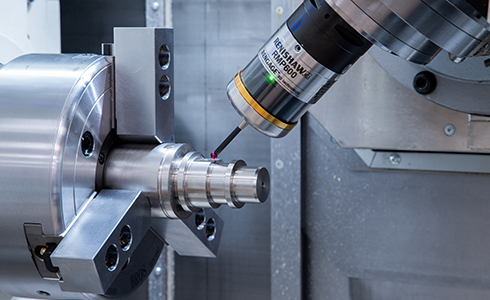

RMP400

RMP600

- RENGAGE™ technology combined with radio transmission for hassle free probing.

- Operating range of up to 15 m.

- Unidirectional repeatability of 0.25 µm 2σ.

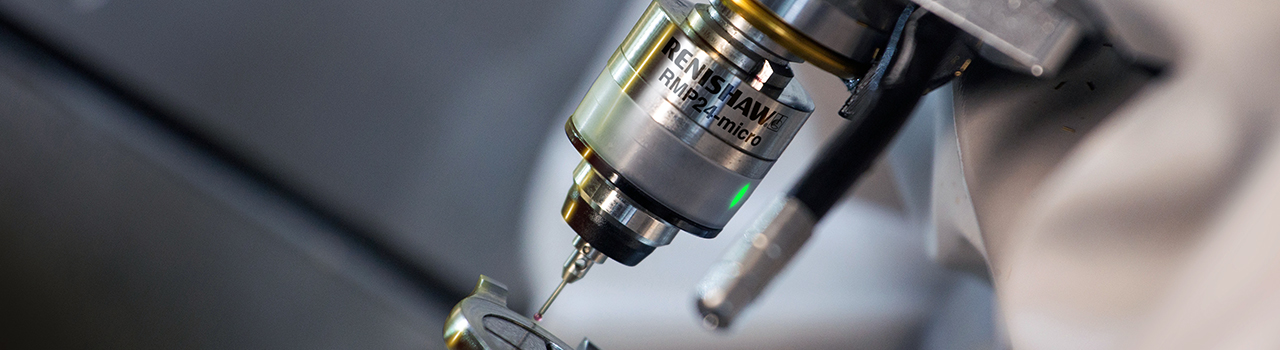

RMP24-micro

As the world's smallest wireless probe, RMP24-micro has been designed for micro precision applications typically found in medical, dental, electronics, jewellery and watchmaking industries. It is the ideal probing solution for machines with small working envelopes, machining high-value parts with delicate surfaces.

- Unrivalled repeatability of 0.35 µm 2σ for a probe so small (24 mm in diameter and 31.4 mm in length).

- Ultra-low trigger forces – with an XY trigger force of only 0.08 N and 0.75 N in Z.

- Maximum power efficiency with QE series transmission protocol.

High-accuracy optical transmission probes

Transmitting at a distance up to six metres, optical transmission is a secure, robust and well-proven transmission method.

OMP400

OMP600

- Proven and patented with RENGAGE technology.

- Secure and robust infrared transmission with operating range up to 5 m (OMP400) and 6 m (OMP600).

- Unidirectional repeatability of 0.25 µm 2σ.

High-accuracy hard-wired probe

MP250

Designed for a minimal footprint and maximum capability, the miniature and versatile MP250 is just 25 mm in diameter and 36 mm in length – providing process control even in the smallest and most harsh machining environments.

- RENGAGE technology for exceptionally reliable measurement over a long service life.

- Battery and interference free with hard-wired connection as standard.

- Unidirectional repeatability of 0.25 µm 2σ.

Increase probing flexibility by pairing the MP250 with the HPGA tool setting arm - a highly repeatable, automated rotary platform, configured to move the probe in and out of the working environment in between cycles.

What is the right probe for my application?

View our high-accuracy probe range and their suitability depending on application. If you would like further assistance, contact your local sales team.

High-accuracy probe comparison matrix

| Recommended machine type | Unidirectional repeatability | Transmission type | Compatible interfaces* | Recommended stylus length | |

| RMP24-micro | Micro-machines and machines with small working envelopes | 0.35 µm (14 µin) 2σ | FHSS Radio | RMI-QE | Up to 30 mm |

| RMP400 | Small to medium machining centres and small multi-tasking machines | 0.25 µm (10 µin) 2σ | FHSS Radio | RMI-Q or RMI-QE** | Up to 200 mm |

| RMP600 | All sizes of multi-tasking machines, machining centres and gantry machines | 0.25 µm (10 µin) 2σ | FHSS Radio | RMI-Q or RMI-QE** | Up to 200 mm |

| OMP400 | Small to medium machining centres and small multi-tasking machines | 0.25 µm (10 µin) 2σ | Optical | OMI-2, OMI-2T, OMI-2H, OMM-2C with OSI/OSI-D, OMM-2 with OSI/OSI-D | Up to 200 mm |

| OMP600 | All sizes of machining centres and small to medium multi-tasking machines | 0.25 µm (10 µin) 2σ | Optical | OMI-2, OMI-2T, OMI-2H, OMM-2C with OSI/OSI-D, OMM-2 with OSI/OSI-D | Up to 200 mm |

| MP250 | CNC grinding machines | 0.25 µm (10 µin) 2σ | Hard-wired | HSI or HSI-C | Up to 100 mm |

*all Renishaw machine tool probes require the purchase of a compatible interface.

** RMI-QE interface is only compatible with QE series probes.

Accurate probe calibration

Calibrate your probe with confidence using ACS-1, and eliminate the need for manual processes that require precision gauge blocks or slip gauges.

Probing made simple with intuitive software

Investing in probing technology enhances your in-process control and establishes a solid process foundation.Renishaw ensures a seamless user experience when using probes. A comprehensive range of macro cycles and machine tool apps allows for quick and intuitive programming of measurement cycles

All-round process control

By measuring a workpiece in-machine with a probe, automated tooling offsets can be made as machining errors occur.

Further enhance your process control by measuring tools as they are setup, to ensure the first cut is right first time, and every time.

Renishaw's range of in-machine tool setters and broken tool detectors can be used in conjunction with our high-accuracy spindle probes to achieve maximum productivity and quality control.

Downloads

Brochures

Data sheets

-

Data sheet: RMP24-micro radio machine probe

Data sheet: RMP24-micro radio machine probe

-

Data sheet: RMP400 (QE) high-accuracy radio machine probe

Data sheet: RMP400 (QE) high-accuracy radio machine probe

-

Data sheet: RMP600 (QE) high-accuracy radio machine probe

Data sheet: RMP600 (QE) high-accuracy radio machine probe

-

Data sheet: RMI-Q radio machine interface

Data sheet: RMI-Q radio machine interface

-

Data sheet: RMI-QE radio machine interface

Data sheet: RMI-QE radio machine interface

-

Data sheet: OMI-2 optical machine interface

Data sheet: OMI-2 optical machine interface

-

Data sheet: OSI with OMM-2 multiple optical probe interface system

Data sheet: OSI with OMM-2 multiple optical probe interface system

-

Data sheet: OMI-2T

Data sheet: OMI-2T

-

Data sheet: OMM-2C optical machine module

Data sheet: OMM-2C optical machine module

-

Data sheet: MP250

Data sheet: MP250

-

Data sheet: HSI high speed interface

Data sheet: HSI high speed interface

-

Data sheet: HSI-C

Data sheet: HSI-C

Looking for support?

Contact us or visit our technical support library for installation manuals, user guides and compliance information.