Was ist ein Messsystem?

Positionsmesssysteme werden in einer Vielzahl von Anwendungen und Branchen eingesetzt und beinhalten verschiedene technische Konzepte und Fachbegriffe.

Dieser Artikel schildert in einfachen Worten, was Positionsmesssysteme sind: Er beschreibt ein Messsystem, die verschiedenen Arten von Messsystemen, ihre Funktionsweise und Einsatzmöglichkeiten.

Was ist ein Messsystem?

Ein Messsystem ist ein elektromechanisches Gerät, das Informationen von einem Format oder Code in ein anderes bzw. in einen anderen umwandelt. Positionsmesssysteme, wie die von Renishaw hergestellten, konvertieren eine translatorische oder rotatorische Bewegung in ein elektrisches Signal, das Informationen über die Position, Geschwindigkeit und Richtung der Bewegung liefert.

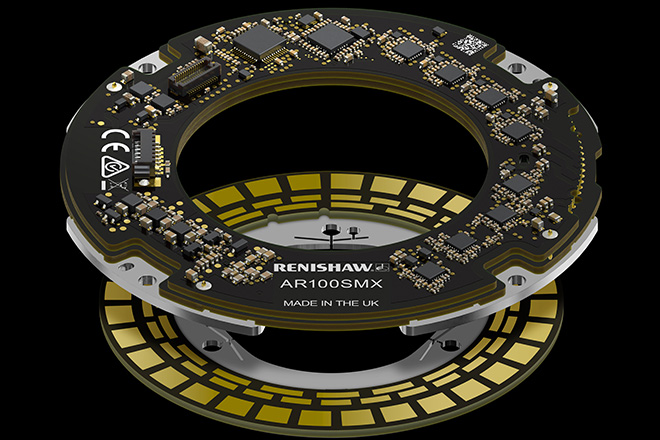

Positionsmesssysteme können verschiedene Sensortechniken nutzen: Renishaw ist auf optische, induktive und laserbasierte Messsysteme spezialisiert. RLS, ein Partnerunternehmen von Renishaw, ist auf magnetische Messsysteme spezialisiert.

Was ist ein optisches Messsystem und wie funktioniert es?

Optische Messsysteme sind Geräte, die mit einer Lichtquelle und einem Fotodetektor arbeiten. Der Detektor bewegt sich an den Linien einer Maßverkörperung entlang und erzeugt dabei ein elektrisches Signal. Dieses Signal kann von dem Regelungsgerät (oder der Steuerung) eines Bewegungssteuerungssystems gelesen werden. Renishaw besitzt mehr als dreißig Jahre Erfahrung in der Entwicklung, Herstellung und Unterstützung von hochleistungsfähigen optischen Messsystemen.

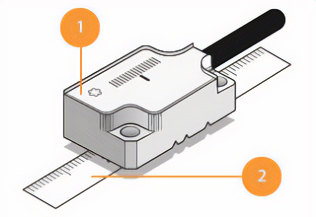

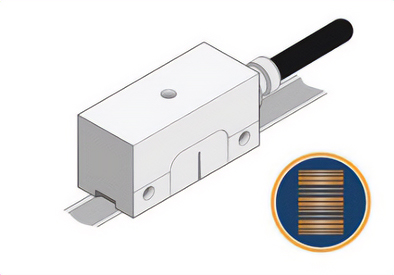

Ein optisches Messsystem besteht aus zwei Komponenten: der Maßverkörperung und dem Abtastkopf.

1: Abtastkopf 2: Maßverkörperung

Die Maßverkörperung des Messsystems

Maßverkörperungen für optische Messsysteme sind mit parallelen dunklen Linien gekennzeichnet, vergleichbar mit den Markierungen auf einem herkömmlichen Lineal. Diese häufig als „Teilung“ bzw. „Teilungsperiode“ bezeichneten Linien werden von einem optischem System im Abtastkopf „gelesen“, um elektrische Signale oder Bilder für die weitere Verarbeitung zu erzeugen. Die Linien auf dem Material der Maßverkörperung sind exakt angeordnet, um die gewünschte Messleistung des Systems sicherzustellen.

Maßverkörperungen für optische Messsysteme können unterschiedliche Formen annehmen, wie beispielsweise flexible Maßbänder, starre Maßstäbe, Scheiben oder Ringe. Diese unterschiedlichen Formen ermöglichen die Messung und Steuerung unterschiedlicher Arten von Bewegungen, wie translatorische, rotatorische, teilrotatorische Bewegungen oder eine Kombination daraus.

Maßverkörperungen für optische Messsysteme müssen stabil und robust sein. Sie werden üblicherweise aus Materialien wie Edelstahl oder Glas hergestellt.

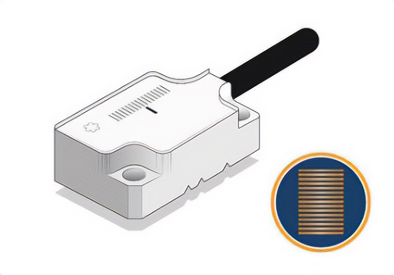

Der Abtastkopf des Messsystems

Im Abtastkopf befinden sich ein optisches System und eine Elektronik. Sie erzeugen ein elektrisches Ausgangssignal, das die Position und Bewegungsrichtung des Abtastkopfes in Bezug auf die Maßverkörperung beschreibt.

Mittels Signalverarbeitung und digitaler Interpolation können optische Messsysteme Bewegungen in Auflösungen bis auf das Milliardstel eines Meters (1 nm) messen.

Ein Nanometer entspricht dem Radius einer DNA-Helix, der Breite von zwei Glukose-Molekülen oder der Wellenlänge eines Röntgenstrahls.

Optische Messsysteme

Messsysteme in offener Ausführung

Ein offenes optisches Messsystem besteht aus einer Maßverkörperung und einem Abtastkopf, zwischen denen ein schmaler Spalt, der sogenannte „Abtastkopfabstand“, besteht. Es ist für die Messung von Weg-, Winkel und Teilkreisbewegungen konfiguriert. Sein berührungsloses Design sorgt für einen Betrieb ohne Reibung, mechanischen Verschleiß oder Hysterese.

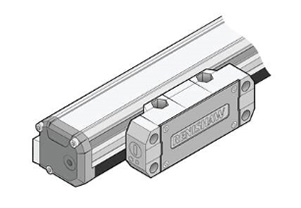

Messsysteme in geschlossener Bauweise

Bei geschlossenen Messsystemen befinden sich die Maßverkörperung und der Abtastkopf in einem hermetisch geschlossenen Gehäuse, welches das Messsystem vor Verunreinigung durch feste Rückstände und dem Eindringen von Flüssigkeiten unter rauen Umgebungsbedingungen schützt. Beispielsweise werden Messsysteme in geschlossener Bauweise üblicherweise auf Werkzeugmaschinen eingesetzt, wo hohe Genauigkeit und Beständigkeit gegen Verunreinigung durch Bearbeitungsrückstände und Kühlschmierstoffe von Bedeutung sind.

Bewegung

Optische Messsysteme können Bewegungen in verschiedenen Formen messen, abhängig von der Art und Struktur der zu messenden Maschinenbewegung.

Linear

Wegmesssysteme erfassen die Position entlang einer Geraden und werden für X-, Y- oder Z-Achsen, wie die eines kartesischen Koordinatenmessgeräts (KMG), verwendet.

Rotativ

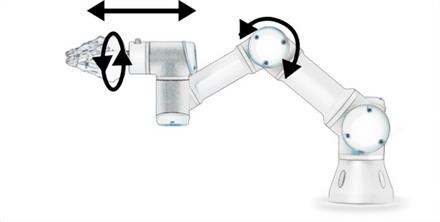

Winkelmesssysteme erfassen die Winkelposition eines rotierenden Teils mithilfe einer Maßverkörperung, die wie ein Ring oder eine Scheibe geformt ist. Diese Messsysteme ermöglichen die Steuerung einer rotativen Bewegung, wie bei einem Drehtisch oder den Gelenken eines Roboters.

Teilrotation

Einige Wegmesssysteme sind flexibel und können um die Trommeln, Wellen oder gekrümmten Flächen einer Maschine gelegt werden, um die Steuerung von Drehbewegungen von weniger als einer ganzen Umdrehung zu ermöglichen.

Welche Unterschiede gibt es zwischen absoluten und inkrementellen Messsystemen?

Inkrementelle Messsysteme können eine Bewegung nur in Bezug auf ihre aktuelle Position oder ein bekanntes Referenzmerkmal erfassen – das ausgegebene Positionssignal erhöht oder verringert (je nach Richtung) die Position jeweils um einen Zähler, während der Abtastkopf die Maßverkörperung abfährt.

Absolute Messsysteme entschlüsseln ihre aktuelle Position sofort – es ist keine Bewegung erforderlich.

Ein wesentlicher Unterschied zwischen dem Verhalten von Inkremental- und Absolut-Messsystemen besteht in ihrer Reaktion auf einen Spannungsverlust. Bei einer Unterbrechung der Stromzufuhr wird der Abtastkopf eines Absolut-Messsystems immer noch in der Lage sein, seine aktuelle Position zu melden, wenn die Stromzufuhr wiederhergestellt wird, selbst wenn er sich während des Stromausfalls bewegt hat. Inkremental-Messsysteme verlieren bei einem Stromausfall ihre Positionsdaten, sodass ihre Bezugsposition nach Wiederherstellung der Stromversorgung erneut erfasst werden muss.

Ein weiterer wesentlicher Unterschied besteht in der Kommunikation: Absolut-Messsysteme verfügen über eine bidirektionale serielle Kommunikation zwischen der Steuerung und dem Abtastkopf. Inkremental-Messsysteme hingegen bieten nur eine unidirektionale Kommunikation über analoge oder digitale Signale vom Abtastkopf zur Steuerung.

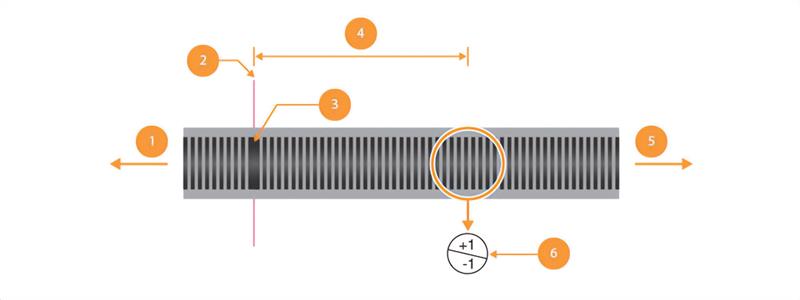

Inkrementelle Position

Die Linien auf einer inkrementellen Maßverkörperung sind in einem einfachen Muster in gleichmäßigem Abstand angeordnet, wie bei einem Lineal, nur ohne Zahlen. Während der Inbetriebnahme wird eine Bezugsposition durch Ablesen einer Referenzmarke ermittelt, die in die Maßverkörperung integriert ist. Die Bezugsposition ist ein fester Bezugspunkt an einer beliebigen Stelle entlang der Messachse, der als Referenzpunkt für die Maschine dient und gelegentlich als „Ausgangsposition“ (Home) bezeichnet wird. Alle Positionsdaten beziehen sich auf diesen Bezugspunkt.

Ein Inkremental-System gibt seine Positionsinformationen im Allgemeinen in Form von zwei analogen Wellen aus, die zueinander um 90 Grad phasenverschoben sind, wie eine Sinus- und eine Cosinuswelle, oder in Form von zwei digitalen Signalen, die um 90 Grad phasenversetzt sind und als „Rechtecksignale“ bezeichnet werden. Die Steuerung kann diese Signale interpretieren, um die Größe und Richtung der Bewegung entlang der Maßverkörperung des Messsystems zu berechnen.

Maßverkörperungen für Inkremental-Messsysteme können in besonderen Längen für Anwendungen mit sehr langen Achsen oder gekürzt auf die gewünschte Länge für beliebige Achslängen hergestellt werden.

1: Richtung bei negativer Zählrichtung, 2: Bezugsposition, 3: Referenzmarke, 4: Position der Steuerung = Anzahl der Zählerwerte ab Bezugsposition, 5: Richtung bei positiver Zählrichtung, 6: Inkrementelle Änderung der Zählrichtung

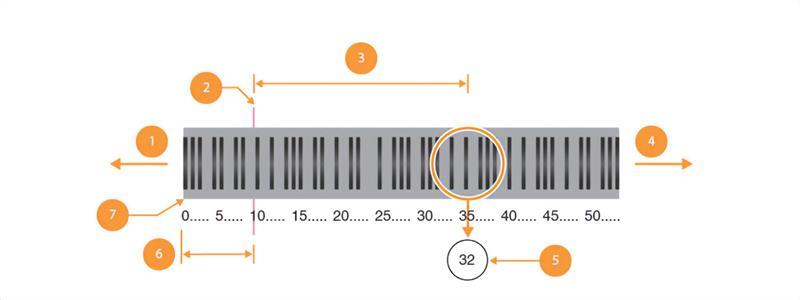

Absolute Position

Ein Absolut-Messsystem verschlüsselt spezifische Positionsinformationen in allen Abschnitten der Maßverkörperung wie ein mit Zahlen versehenes Lineal. Diese spezifischen Positionswerte werden durch einen Satz paralleler Linien definiert, wobei einige der Linien ausgelassen werden, ähnlich wie bei einem Barcode. Über dieses sich wiederholende Muster kann der Abtastkopf seine Position direkt bei der Inbetriebnahme finden.

Die Steuerung wird in regelmäßigen Abständen Positionsdaten vom Abtastkopf abrufen, der daraufhin ein Bild der Maßverkörperung aufnimmt und das Bild in einen spezifischen Positionswert entschlüsselt, der dann über ein serielles Kommunikationsprotokoll an die Steuerung zurückgegeben wird.

Es stehen verschiedene industrieübliche Kommunikationsprotokolle zur Verfügung, die häufig bestimmten Steuerungsherstellern zuzuordnen sind.

Maßverkörperungen für Absolut-Messsysteme stützen sich auf kurze, eindeutige Muster (oder Worte) aus Linien und Abständen zur Bestimmung einer Position. Da diese Worte eine endliche Anzahl möglicher Anordnungen haben, sind Maßverkörperungen für Absolut-Messsysteme auf eine maximale Länge begrenzt. Im Fall des RESOLUTE™ Absolut-Messsystems von Renishaw beträgt diese maximale Messlänge 21 Meter.

1: Richtung bei negativer Zählrichtung, 2: Bezugsposition, 3: Position der Steuerung = Position des Abtastkopfes – numerischer Offset, 4: Richtung bei positiver Zählrichtung, 5: Absolute Position, 6: Numerischer Offset der Bezugsposition, 7: Position „Null“

Wo würde ich ein inkrementelles Messsystem einsetzen?

Inkremental-Messsysteme kommen in einer Vielzahl von Bewegungssteuerungsanwendungen wie Fabrikautomatisierung, Koordinatenmessgeräte (KMG) und Anlagen für die Halbleiterfertigung zum Einsatz. Inkrementelle Messsysteme ermöglichen genaue Positionsmessungen mit feinen Auflösungen und hohen Scangeschwindigkeiten.

Wo würde ich ein absolutes Messsystem einsetzen?

Absolut-Messsysteme eignen sich hervorragend für Maschinen, die Positionsdaten auch nach dem Aus- und Wiedereinschalten beibehalten müssen. Zu den Anwendungen zählen chirurgische Roboter und Maschinen, bei denen das Anfahren fester Referenzmarken in Referenzierzyklen nicht erwünscht ist.

Wo werden optische Messsysteme eingesetzt?

Optische Messsysteme sind vielseitige Positionsmessgeräte, die in einem breiten Anwendungsspektrum für die Messung und Steuerung von translatorischen oder rotatorischen Bewegungen eingesetzt werden.

Sie werden in vielen Branchen und Anwendungen wie Messtechnik, Halbleiterfertigung, Robotik, Automatisierung, Werkzeugmaschinen und wissenschaftliche Forschung verwendet.

Was ist ein induktives Messsystem?

Ein induktives Absolut-Messsystem ist eine Art Positionssensor, der elektromagnetische Induktion nutzt, um die Position oder Bewegung einer Achse zu messen.

Induktive Messsysteme bieten Robustheit, Verschmutzungsbeständigkeit, Unempfindlichkeit gegenüber externen Magnetfeldern und eine gute Genauigkeit.

Zu den Anwendungen zählen kardanische Aufhängungen (Gimbals), medizinische Geräte. allgemeine Automatisierung, unbemannte Luftfahrzeuge (UAV), Roboter und Servomotoren.

Weitere Informationen zu induktiven Messsystemen von Renishaw finden Sie auf unserer Webseite ASTRiA™ inductive rotary absolute encoders.

Was ist ein magnetisches Messsystem?

Magnetische Messsysteme verwenden eine Maßverkörperung, die über wechselnde Pole magnetisiert wird. Die Bewegung entlang der Maßverkörperung wird durch einen Abtastkopf ermittelt. Dieser enthält einen Sensor, der die Veränderung des Magnetfelds während der Bewegung des Abtastkopfes erfasst und in ein elektrisches Signal umwandelt.

Magnetische Messsysteme werden häufig in der Robotik (wie beispielsweise autonomen Transportsystemen, AGV) und Druckanwendungen verwendet.

Weitere Informationen zu magnetischen Messsystemen finden Sie auf der RLS Webseite.

Was ist ein Laser-Messsystem?

Laser-Messsysteme verwenden die Wellenlänge eines Laserlichts als Maßeinheit, indem sie die Abweichungen in der Weglänge zwischen einem festen Referenzpfad und einem variablen Messpfad erfassen. Laser-Messsysteme verbinden hochgenaue Positionsmessung mit feiner Auflösung.

Laser-Messsysteme kommen häufig in Branchen wie der Luft- und Raumfahrt, Seefahrt sowie anderen Spezialanwendungen zum Einsatz.

Weitere Informationen zu Laser-Messsystemen von Renishaw finden Sie auf unserer Webseite Interferometric laser encoders.

Schauen Sie sich unsere Webinar-Aufzeichnungen an

Das Webinar „Einführung zu Messsystemen“ beschreibt in einfachen Worten die Funktionsweise eines Messsystems (auch „Encoder“, „Drehgeber“ oder „Positiongeber“ genannt).

Es erklärt die Funktion der Maßverkörperung und des Abtastkopfes, die verschiedenen Arten der zur Verfügung stehenden Messsysteme, ihre Funktionsweise und Einsatzmöglichkeiten.

Zum Anschauen der Aufzeichnung anmelden

Kontaktieren Sie noch heute unser Vertriebsteam

Für weitere Informationen setzen Sie sich bitte mit Ihrer Niederlassung in Verbindung und sprechen Sie mit einem Experten.