Navigation

PH10M-iQ PLUS system description

| Product | Description |

| PH10M-iQ PLUS | A shank-mounted head with multiwired probe capability, a Renishaw autojoint and inferred qualification |

| HCU2 | A hand control unit for use with PH10 measurement systems |

| PHC10-3 PLUS | A controller for use with PH10 measurement systems |

| UCC T3 PLUS | Renishaw CMM controller with integrated PH10 PLUS controller |

| UCC S3 | Renishaw CMM controller with integrated PH10 PLUS controller |

The PH10M-iQ PLUS is a general purpose, versatile unit designed specifically for use on direct computer controlled (DCC) CMMs and incorporates the following features:

- 720 indexing positions

- 0.4 μm indexing repeatability

- 7.5° indexing steps in both axes

- 300 mm extension bar capability *

- Inferred qualification when mounted vertically or horizontally **

* NOTE: 450 mm extension bar capability with special order carbon fibre extensions.

** The inferred calibration procedure is different depending on the chosen orientation of the head.

WARNING: The components of the PH10M-iQ PLUS system are not compatible with PH9 and PH20 system components. No attempt should be made to connect the PH10M-iQ PLUS system components to a PH9 or PH20 system as this will result in damage to the product.

NOTE: On initial set-up of a PH10M-iQ PLUS system, a head localisation is required. Please refer to the software providers' documentation for more information.

Specification

| Repeatability of position (at a distance of 100 mm) | <0.4 μm TP6A and stylus |

| Accuracy of step spacing from theoretical position | ±0.3 mm TP6A probe and stylus |

Positioning

| Step | 7.5° |

| A-axis 0° to 105° | 15 positions |

| B-axis -180° to +180° | 48 positions |

| Total | 720 positions |

| Probe mounting | Multiwired autojoint |

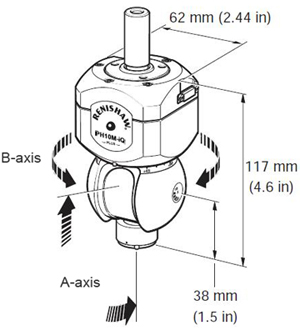

Dimensions from quill face

| XY | 62 mm |

| Z | 117 mm |

| Weight | 620 g |

PH10M-iQ PLUS body dimensions

CAUTION: Please ensure that the head is mounted as rigidly as possible in the CMM's quill. Avoid collisions between the head, workpiece or CMM bed, ensuring that the head is moved clear of any obstruction before requesting a position change. Do not apply force to any moving parts of the head and do not move the head axes by hand when locked or unlocked.