Navigation

ACR1 fault finding

Errors

Error mode

The system enters error mode if any of the following occurs:

- an error occurs in the change cycle

- the system is switched on with no rack connected

- an overtravel error occurs

- an invalid command is received *

- a command is received while the system is busy *

- an external PICS STOP (STOP signal) is received

* The system returns to normal operation after reporting these errors.

NOTE: It is recommended that the probe is supported during removal from the ACR1 if the lock cycle has failed and the autojoint is not secured to the head.

LED sequences and diagnosis

LED fault diagnosis

The table below shows the status of the rack and ACC2-3 LEDs and indicates the following fault conditions:

NOTE: For further information about RS232 CTS see the 'RS232 communications' section in Autochange system installation and programmer's guide (Renishaw part number H-1000-6012).

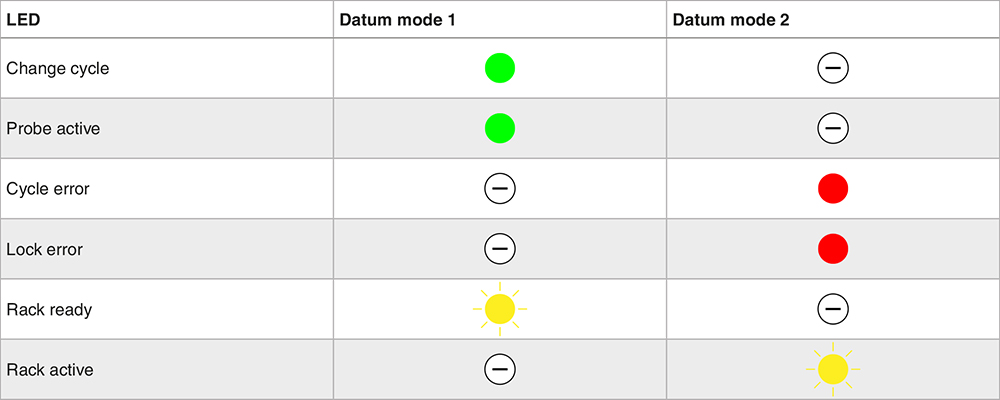

Datum mode indication

The following table shows which LED sequences are used to indicate that the system is in datum mode:

Corrective action

Most of the error modes discussed in the 'Errors' section occur during the probe change cycle.

Preliminary action

In the event of an error, the machine will stop and the appropriate LEDs will light up.

The operator should then attempt to back the head out and away from the docking port in the exact reverse sequence to the way it was moved in. Care must be taken to support the probe / extension bar, which is unlikely to be secure in the case of a probe change cycle being aborted.

Further troubleshooting

UNLOCK / LOCK TIMEOUT ERROR

In the event of a lock / unlock timeout error, it may be the case that the port lid is jamming or sticking. Ensure that the lid can open and shut smoothly and check for contamination of the sliding surfaces.

RACK OVERTRAVEL

For a diagnosed rack overtravel error, the possible causes are:

- Excessive entry speed, which can be adjusted as necessary

- The rack or head is not properly aligned (see sections 'Aligning the head' and 'Aligning the rack' for correct alignment procedure)

- A collision due to a program error

- The probe / adaptor has been manually locked onto the head and the ‘screwdriver slot' angle is incorrect

NOTE: If a probe extension bar is manually locked (using an S10 autojoint key), it is advisable to lock it fully to the cam end stop then back the screwdriver slot off by approximately 5. If this is not done, it is unlikely that the probe will dock into the autochange rack.

- The probe / adaptor has been picked up from one port and put down in a different one. This is not good practice and can cause a problem if a move to or from port 8 is involved.

PROBE HEAD COLLISION

If the probe head should come into contact or collide with the rack, the alignment of both the rack and the head must be checked and re-aligned if necessary, as described in the relevant sections. In the case of a head collision involving a rack port, it may be necessary to check the port-to-rack alignment - see table below (excessive wear on ports). It is essential to correctly align the rack and the head to the CMM axes for smooth, wear-free operation.

GENERAL CHECKS

If the system is not working properly and the cause of the problem is unknown, run through the checks shown in the table below:

Troubleshooting

Symptom | Possible causes | Action |

|---|---|---|

System fails to start working | Discontinuity within system | Check fuse and mains supply. Check all cables and connections. |

Spurious triggers | Vibration | Ensure that the head is not subject to machine vibration. Check machine speed. Check probe trigger force. |

Excessive wear on ports | System incorrectly aligned Some ports are out of alignment with the rack | See sections 'Aligning the head' and 'Aligning the rack'. Check the alignment of the top face of each port: if they are more than 100 m (0.004 in) out relative to each other return the ACR1 to Renishaw or your distributor / supplier. |

Triggers on contact with autochange port | High entry speed causing vibration trigger on impact Probe sensitivity set too high | Reduce the docking speed. Fit a self-adhesive shock absorbing pad (M-1085-0294) to the male autojoint housing of the probe head at the point of contact with the ACR1 docking ports. |

If there is any doubt about the cause of a problem, or about system performance in general, please contact the measuring machine or autochange supplier.