Stunning large-scale images achieved with speed and repeatability

More than 500 years after England's printing pioneer produced the country's first books, we live in a world obsessed with the printed image, where product packaging, billboards, shop window displays, bus shelters and almost every available product and public space is taken up with a high-resolution visual image or photograph. These images are so ubiquitous that the only time we really take notice of them is either when they're absent, or when they're particularly eye-catching.

The build quality of a printer has a direct impact on the print quality. Even the tiniest misalignment in the machine's chassis can be amplified, through the print “head” causing “banding” and other registration errors which show up in the image. Certainly not what you get when you buy a printer from Inca, especially if you're paying more than £1million for the company's largest and latest design.

Meeting customer demands with calibration

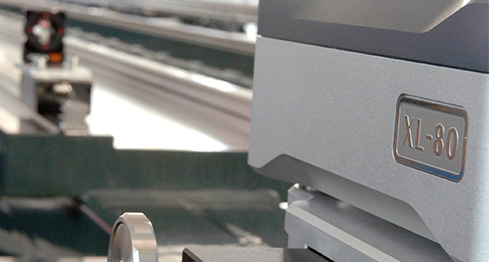

“Today's printing companies want a combination of speed, quality and repeatability,” says Inca's Director of Technology, Dr. Will Eve. “They also want print at large sizes, which makes the other three more difficult to attain. To help us achieve all four, we check all of our printers with a Renishaw XL-80 laser.”

Renishaw has been designing and manufacturing laser interferometer systems for over 20 years. In fact, before Inca invested in the Renishaw XL-80, the company had been using one of Renishaw's most successful laser systems: the ML10. With its ±0.7 ppm linear measurement accuracy it established the global benchmark for the calibration systems used on machine tools, co-ordinate measuring machines and other position and motion critical systems.

Building on the success of the ML10, the new compact XL-80 has a linear measurement accuracy of ±0.5 ppm and a greatly improved dynamic measurement performance, including a maximum linear measurement speed of 4m/s.

Calibrating long rails at high speed

“We use the XL-80 for both static and dynamic measurements,” says Dr. Eve. “When we're building our machines, we take measurements along the length of the main rails - some of them up to 11.5m - to make sure the chassis is aligned when it arrives from the fabricator. Then, when the machine is built, powered up and tested, we use the Renishaw XL-80 to measure the accuracy and repeatability of the moving machine. Although our previous ML10 laser was excellent for up to 1 m/s measurements it could not measure at the machine's full speed. With the high speed measuring performance of 4 m/s of the new XL-80 we can now discover any positioning errors and store the error values in a file in the machine's control system. This then uses the values as the basis for its dynamic compensation. So we know the printer head will always move as intended.”

Amongst other things, the new XL-80 was conceived with portability in mind. It is much smaller and lighter than its predecessor which, for a company like Inca Digital, where its large machines are built in situ around its ever-expanding assembly and testing area, is a considerable benefit.

XL-80 portability

“We need to be able to quickly move the XL-80 from one area of the factory to another,” says Inca's Mike Cummins. “The fact that the whole system fits into a relatively small case, which one man can carry comfortably, is a great attribute.”

“Once in a while we also take the laser on site,” adds Dr. Eve, “to recalibrate a customer's machine in the field - this could be anywhere: the US, Canada, Europe, Japan, China, Australia or New Zealand...In these cases the compact size and light weight makes it easy and economical to take the XL-80 on a plane.”

All of which adds up to a beautiful, pin-sharp image, time after time.