Flying success with Dunlop Aerospace Braking Systems

Dunlop Aerospace Braking Systems, a part of Meggitt plc, is a global organisation that designs, develops and manufactures wheels and brakes for commercial and military aircraft applications.

Aircraft production in the UK has experienced steady growth and to meet this demand the hub and flange cell at Dunlop Aerospace purchased 3 key CNC machines between 1998 and 2000, at that time actively specifying Renishaw probe systems. This has increased process consistency and has also had a marked effect on the manufacturing time.

Dramatic reductions

Andrew Cartledge, team leader of the hub and flange cell, speaks positively about the decision to employ Renishaw probing systems, "We've seen improvement both in machining cycle times and the overall set times every time we've introduced a component to the cell. This is critical to our New Product Introduction process (NPI) which we use every time a new wheel is introduced, essentially allowing us to 'design for manufacture."

Runners, repeaters and one-offs

Orders for wheels fall into three different categories according to the number of batches made each year. The 'runner' orders are classed as those wheels produced in more than 10 batches a year; 'repeaters' are less than 10 batches a year. Dunlop Aerospace also supply one-off orders and recently succeeded in a very impressive project to re-manufacture components for the 1950s Canberra. This involved taking original drawings and re-programming the machining through the modern CNC process.

Mr Cartledge continues, "NPI involves a process we call Manufacturing Process Approval (MPA) whereby any machining process must be closely analysed to see if it affects the stresses and component strengths of a wheel assembly. All the main ‘runners' and any ‘repeaters' that are introduced to the new cell need MPA before production can start."

Investment in technology and automation

Between 1998 and 2000 Dunlop Aerospace chose to spend nearly £2 million on three state of the art multi-axis CNC machines; a multi-axis Mazak Integrex - a turning centre with full C-axis and driven tooling to give milling capability; a Mazak HV800 5-axis horizontal machine centre; and the most recent investment, a Mori-Seiki MT4000, at the time the first of its type in the UK.

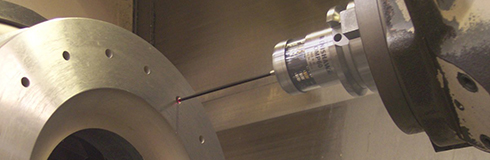

Probe systems make all the difference

The underlying technique made possible by the integration of the probe systems is the ability to identify the component position and material condition, updating and monitoring the deviation in the wheel forgings. This reduces cutting time, as it eliminates fresh-air cuts - this is because the probe ensures that the critical surfaces of forgings are accurately located and metal cutting starts immediately.

The importance of one hit machining

During the cutting process stresses are relieved in the material, so one hit machining results in the cutting process achieving greater consistency. L77 aluminium is the most commonly used material and, with the high cost of each process, it is essential that Dunlop Aerospace keep scrap levels low. In-process monitoring and tool offset updating ensures process control and minimises scrap.

The nature of the aviation industry demands ever-increasing accuracy and quality, ensuring both wheels and brakes can be reliable in all conditions and scenarios. Mr Cartledge sums up the changes to the process neatly - "We have now used probing systems on this cell for over 6 years and have cut costs and times, with a step change in process control and consistency."