Additive manufacturing technology enables servo valve innovation

With the help of metal additive manufacturing (AM) technology from global engineering company, Renishaw, UK-based Domin Fluid Power Ltd. (Domin) has produced a new range of direct drive valves. Founded in 2012, in Bristol, Domin, is disrupting the hydraulics industry by redesigning servo valves from first principles to achieve a better performing, more sustainable product at a lower price point.

Background

“While there has been a huge amount of innovation across the manufacturing industry in the last few decades, none of it has been significant enough to achieve true disruption in the fluid power sector,” explained Marcus Pont, Chief Executive Officer of Domin. “Much of the fundamental technology in our industry was established decades ago, little has changed until now.”

“We believed that metal AM was the final puzzle piece and we're confident we could generate true industry change and make a positive impact,” continued Pont. “By combining AM with other innovations like high-speed motor control, modern electronics, big data and connected technology, there is real potential for disruption.”

“There is a compelling reason disruption is needed — sustainability. In the US, the fluid power sector alone wastes about 300 million tonnes of CO2 per year through system inefficiencies,” added Pont.

“To put this into context, this is about the same as the total output for all CO2 emissions in the UK. More efficient technology could make a real difference to global emissions.”

Metal AM involves building a solid metal component layer-by-layer from metal powder. Due to its inherent design freedom, additive manufacturing enables Domin to build complex parts, free of tooling and with minimal operations and assembly. For example, metal AM provides the ability to design complex geometries with internal features like lattices and cooling channels. It produces parts with good strength-to-weight ratio and creates less waste.

Challenge

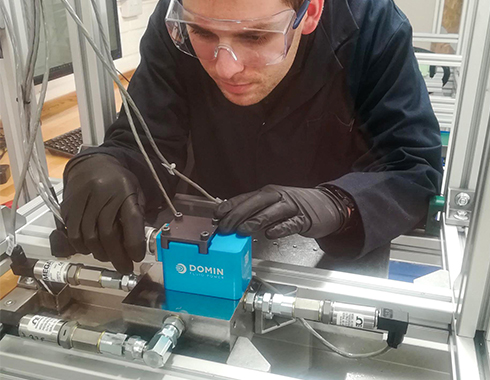

Additively manufactured direct drive valves from Domin

Despite the huge potential of the technology, AM has traditionally been used in low-volume custom applications in aerospace, medical and automotive, rather than in high-volume, off-the-shelf products like valves.

“Some of the traditional barriers to additive manufacturing were limited production speed, the cost of a machine and variation in build quality between machines,” said Bryan Austin, Director of Sales at Renishaw's Additive Manufacturing Group. “While AM grew in popularity for rapid prototyping, many companies are yet to realise the benefits it can bring to series production.”

Domin redesigned its servo drives from first principles for the AM process. It wasn't just a redesigned manifold, but an entirely different product. This involved combining and removing components and using clever hydraulic connections to reduce both mass and volume. The company spent several years testing different prototype designs to produce drives that were smaller, lighter and more powerful. However, it needed a way to produce them economically.

Every valve we sell saves over a tonne of CO2 per year compared with alternative products. The next step for us is to improve the efficiency of hydraulic systems by 400 per cent, which could make a real difference to global emissions.

Domin Fluid Power Ltd. (UK)

Solution

Recent innovations in the AM market have seen the introduction of multi-laser machines. The RenAM 500Q, Renishaw's four laser system, was the solution that Domin needed to produce its new range at a competitive price point.

The machine features four 500W lasers, each able to access the entire powder bed simultaneously, which means it can achieve significantly higher build rates — up to four times as fast as a single laser system. By improving productivity and decreasing cost per part, it is broadening the appeal of AM into applications where it was previously uneconomical.

The system also offers automated powder and waste handling systems that enable consistent process quality, reduced operator intervention time and ensures high standards of safety. Alongside this, the machine offers intelligent gas flow to remove process emissions and extend filter life. It can be combined with Additive Manufacturing Process Monitoring (AMPM) software to improve quality, overcoming another traditional barrier.

“We could see that Domin and Renishaw had a shared vision,” added Austin. “We wanted to be part of Domin's journey to disrupt the market. Because Domin already had a fully designed product but needed a productive route to market, we started a project to prove the production capabilities of the RenAM 500Q for the specific application and to ensure the manufacturing process was consistent, stable and could provide the required throughput.”

Renishaw also provided input into printing strategies, for example making recommendations about how to increase heat dissipation, such as allowing more time to cool between each layer during the first 130 layers. Another option was to decrease the energy input by using fewer layers or building support structures with just two lasers, while building the parts with all four, exporting them as separate geometries from CAD.

The build process takes 17 hours and 21 minutes, with a machine set-up time of 30 minutes. Twelve parts are produced on each build plate, with each laser producing three components. Renishaw also designed support structures to enable easy powder removal.

"The productivity of the RenAM 500Q is what enabled us to take our range to market competitively. It significantly drove down cost per part compared with alternative machines," emphasised Pont.

Results

The company has now launched its range of off-the-shelf electrohydraulic valves for servo applications, which perform better than current state-of-the-art products, and cost less to produce. Customers can easily configure the design online to order valves with good power density and dynamic performance. They are suitable for use in a broad range of applications, from injection moulding machines, to actuation on vehicles and landing gear in aeroplanes. Domin is already working on projects with leading businesses, such as Aston Martin Lagonda.

“Our range of valves is just the first step of a bigger picture for us,” explained Pont. “We've already proven that AM can be used in genuine series production of off-the-shelf products in a cost sensitive market. Long term, we plan to create change across entire systems and develop complete solutions for the fluid power sector.”

“Every valve we sell saves over a tonne of CO2 per year compared with alternative products,” added Pont. “The next step for us is to improve the efficiency of hydraulic systems by 400 per cent, which could make a real difference to global emissions.”

“Britain has several of the world's leading engineering companies — Renishaw included — but the majority of these were founded in the 20th Century,” continued Pont. “It is time that smaller businesses raised their aspirations. It's really exciting to see what can be achieved using the latest technology from British business and seeing the potential value that engineering innovation can drive for UK industry.”

“Renishaw is always looking for opportunities to develop emerging technologies that can make a positive change to the wider industry,” added Austin. “AM is a key enabling technology in this application, as it provides the technical and commercial benefits needed for Domin to make high performance, lightweight parts rapidly and cost effectively. We're excited to see what it achieves in the future.”

Domin's direct drive valve