Tato stránka není v současné době k dispozici ve vašem jazyce. Automatizovaný překlad můžete zobrazit pomocí nástroje Google Translate. Neodpovídáme za poskytování této služby a výsledky překladu jsme nekontrolovali.

Potřebujete-li další pomoc, kontaktujte nás.

Pioneering additive manufacturing reshapes patient’s face

Additive manufacturing (3D printing) is changing and improving many traditional industries and processes. Healthcare is no exception with reconstructive surgery being particularly prominent.

A horrific motorcycle accident left Stephen Power with multiple skull fractures that changed his life and meant he would require reconstructive surgery. Professor Adrian Sugar, a consultant in Cleft and Maxillofacial Surgery at Morriston Hospital in Swansea, UK was keen to push the boundaries of his profession and embrace new techniques and processes, in order to help Stephen.

Stephen had already undergone emergency surgery to reconstruct his face. However, with an emphasis on recovery rather than appearance, Stephen would require subsequent surgery to restore symmetry to his face.

Renishaw worked in collaboration with the Centre for Applied Reconstructive Technologies in Surgery (CARTIS) in South Wales, to develop surgical guides. Soft tissue incisions and bone positioning can involve freehand incisions making this type of surgery more complex than perhaps it might otherwise be and with less predictable outcomes. Surgical guides were created to overcome this.

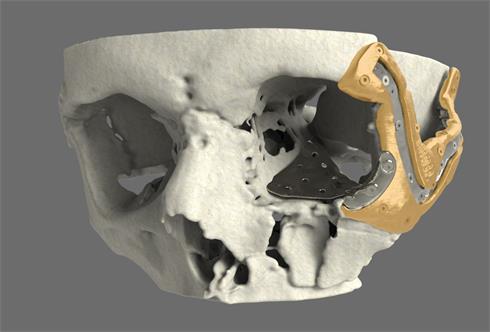

Although the surgical procedure itself was still time consuming and onerous, professor Sugar felt that the guides, which were manufactured on a Renishaw AM250 metal 3D printing machine, made the surgery quicker and more accurate.

Prior to surgery plans were drawn up to decide where to make bone incisions, and custom made guides were made in order to remove some of the guess work that this type of surgery inevitably presents. This planning, together with the surgical guides, made for a near perfect fit for two permanent implants and a more efficient operation.

Professor Sugar felt that the guides resulted in a more predictable outcome and said, “I think it's incomparable - the results are in a different league from anything we've done before.” Stephen's response was even more emphatic: “It is totally life-changing.” Surgery took place to put Stephen's cheek bone back into place. The use of custom surgical guides is still in its infancy with a number of steps required to reach the final outcome.

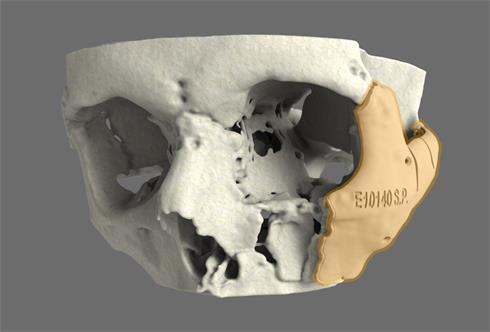

In order to achieve symmetry in Stephen's face, the surgical team took computerised tomography (CT) scans of his head. The CT data allows the surgeons to assess the state of his skull and plan the surgery. This “pre-operative” CT data was fed into a powerful computer aided design (CAD) package which allowed the team to design the “post-operative” bone structure that would achieve the best symmetry.

Using the pre-operative and post-operative design data, two metal guides were designed and produced for each stage of the surgical process: a cutting guide and a repositioning guide. The cutting guide was used to cut the zygomatic (cheek) bone, in specific locations, so the bone sections could be used in a cheek reconstruction. The repositioning guide allowed the bone sections to be placed in their final location before placing a zygomatic implant and orbital floor.

I think it's incomparable - the results are in a different league from anything we've done before.

Professor Adrian Sugar (UK)

The zygomatic implant holds the repositioned bone sections in position and allows them to heal, whilst the orbital floor lifts the eyeball so that it is level with Stephen's other eye.

The titanium implants, printed in Belgium, remained in place once the guides were removed. The additive manufacturing process allowed Professor Sugar more flexibility in the design of the guides and implants. Stephen commented that he would “be able to do day-to-day things, go and see people, walk in the street, even go to any public areas.”

The project was the work of the Centre for Applied Reconstructive Technologies in Surgery (CARTIS), which is a collaboration between Abertawe Bro Morgannwg University Health Board's Maxillofacial Unit at Morriston Hospital and the National Centre for Product Design and Development Research (PDR) at Cardiff Metropolitan University.

Renishaw supplied the cutting and placement guides which were 3D printed in cobalt chrome alloy on a Renishaw AM250 additive manufacturing machine. Renishaw is the only UK manufacturer of a metal 3D printing machine. Designing and developing the machine at its Stone (Staffordshire) and Gloucestershire sites, and manufacturing the machine at its site in Miskin near Cardiff.