Tato stránka není v současné době k dispozici ve vašem jazyce. Automatizovaný překlad můžete zobrazit pomocí nástroje Google Translate. Neodpovídáme za poskytování této služby a výsledky překladu jsme nekontrolovali.

Potřebujete-li další pomoc, kontaktujte nás.

BiSS® protocol support

What is the BiSS C interface?

BiSS C-mode (unidirectional) is a fast synchronous serial interface for acquiring position data from an encoder.

It is a master-slave interface. The master controls the timing of position acquisition and the data transmission speed and the encoder is the slave. The interface consists of two unidirectional differential pairs of lines:

- “MA” transmits position acquisition requests and timing information (clock) from master to encoder.

- “SLO” transfers position data from encoder to master, synchronised to MA.

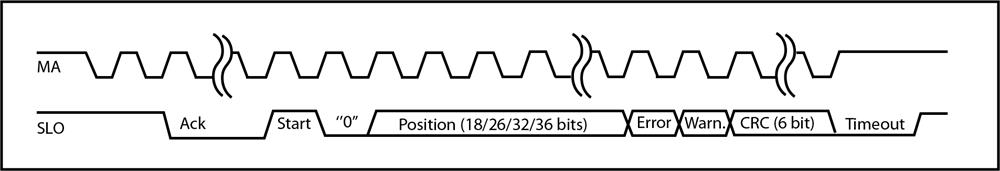

The following diagram shows the transmitted data.

Data format

What is the BiSS Safety interface?

BiSS Safety is a fast synchronous serial interface for acquiring position data from an encoder in applications requiring Functional Safety. The RESOLUTE™ Functional Safety (FS) encoder and the FORTiS™ Functional Safety (FS) encoder use BiSS Safety communications and are certified to the following Functional Safety standards:

- ISO 13849 Category 3 PLd

- IEC 61508 SIL2

- IEC 61800-5-2 SIL2

BiSS Safety is a master-slave interface. The master controls the timing of position acquisition and the data transmission speed, and the encoder is the slave. The interface consists of two unidirectional differential pairs of lines:

- “MA” transmits position acquisition requests and timing information (clock) from master to encoder.

- “SLO” transfers position data from encoder to master, synchronised to MA.

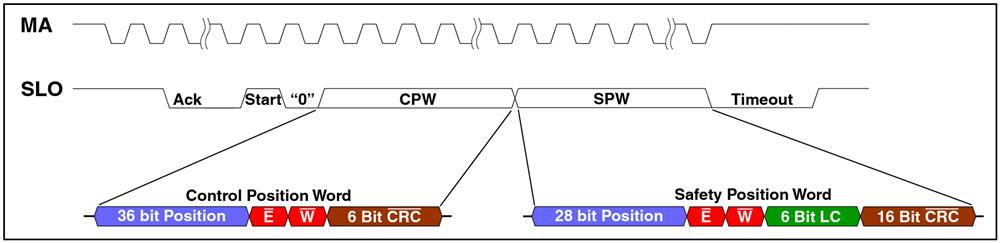

The following diagram shows the transmitted data.

The master-slave signal communication format is RS485 / RS422 differential line-driven.

Data format

A typical request cycle proceeds as follows:

When idle, the master holds MA high. The encoder indicates it is ready by holding SLO high.

- The master requests position acquisition by starting to transmit clock pulses on MA.

- The encoder responds by setting SLO low on the second rising edge on MA.

- After the “Ack” period is complete, the encoder transmits data to the master synchronised with the clock as shown in the preceding diagrams.

- When all data has been transferred, the master stops the clock and sets MA high.

- If the encoder is not yet ready for the next request cycle, it sets SLO low (the Timeout period).

- When the encoder is ready for the next request cycle, it indicates this to the master by setting SLO high.

Compatibility of Renishaw encoders

- Rotary encoders are single-turn (with 2n counts per revolution and no revolution counting).

- Linear encoders are available with a range of different resolutions (and maximum measuring lengths) as specified on the product data sheets.

BiSS compatible controllers

The BiSS interface is supported by a wide range of controller manufacturers, such as ABB, KEB, Galil, ACS, Beckhoff, Elmo and Kollmorgen. Further information about BiSS compatible products is available from the BiSS interface website.

Downloads: datasheets and technical documents

Further information about the technical specifications of the absolute encoder series, such as datasheets and installation guides, are available from our technical downloads section.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.