Case study: Renishaw technology helps Breton calibrate its in-house machinery and control the quality of its output (pdf)

When Breton SpA wanted to add machine tool manufacture to its core business of building stone-processing machinery, the increase in required levels of precision prompted the introduction of around 30 devices from Renishaw, including laser interferometers, rotary axis calibrators, ballbars and touch-trigger probes. As a result, Breton’s range of high-speed, five-axis CNC machining centres are now among the world’s most advanced.

This type of file requires a viewer, freely available from Adobe

Latest videos - Machine calibration and optimisation

-

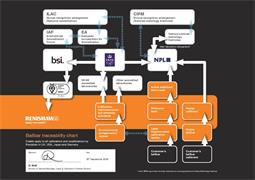

Empowering calibration service providers to deliver precision solutions

Empowering calibration service providers to deliver precision solutions

-

Precision calibration products helps produce high-quality, high-end machine tools.

Precision calibration products helps produce high-quality, high-end machine tools.

-

Renishaw FORTiS enclosed optical encoders and XK10 alignment laser system for precision machine tools

Renishaw FORTiS enclosed optical encoders and XK10 alignment laser system for precision machine tools

-

Renishaw Central closed-loop process control on the shop floor

Renishaw Central closed-loop process control on the shop floor

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.