Navigation

SFA surface finish artefacts

Renishaw provides a range of products that support the use of REVO® SFP2 surface finish measurement probes on CMMs.

The artefact plates are used for calibrating surface finish modules, independently verifying the calibration, checking linearity and tip condition monitoring.

Additionally, Renishaw's condition checking artefact can be used to position optical flats and calibration plates throughout the CMM volume. This may be useful in assessing a machine's capability for surface roughness measurement.

The TFP tip find probe comprises a TP20 probe with low force module. It is used to map the SFP2 probe C-axis and calibrate the geometry of module / holder configurations.

SFA artefact comparison chart

Function | Surface details | Traceability | |

SFA1*  | Used for calibrating SFM surface finish modules. | 3.0 μm Ra sinusoidal profile. Electroformed nickel surface. | UKAS calibration certificate provided. |

SFA2*  | Used for checking calibration linearity. | 0.5 μm Ra sinusoidal profile. Electroformed nickel surface. | UKAS calibration certificate provided. |

SFA3*  | Used for periodic tip condition checking. | 0.4 μm Ra saw tooth profile. Electroformed nickel surface. | UKAS calibration certificate provided. |

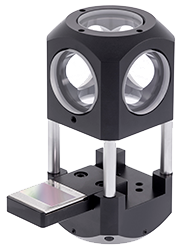

OFA**  | A service tool for verifying machine capability and fault finding. It houses six optical flats located within a cube and has mounting holes for additional calibration and checking artefacts. | l/20 fused silica optical flat. Diameter 50 mm. | Optical flats are supplied with calibration certificates. |

* SFA1, SFA2 and SFA3 can be fixed to an MRS2 rail, MRS2 leg or the OFA artefact. These artefacts and mounts can be supplied within comprehensive system kits or individually.

** OFA can be mounted directly to the bed of a CMM, to a fixture plate or to a universal calibration tower. The OFA is available to special order only. Contact Renishaw for availability.

Part number | |

REVO SFP2 kits | |

SFP2 combi kit #1 (A1 and A2 modules, single artefact) | A-5764-0001 |

SFP2 combi kit #2 (single artefact, no modules) | A-5764-0002 |

SFP2 combi kit #3 (A1 and A2 modules, triple artefact) | A-5764-0003 |

SFP2 combi kit #4 (triple artefact, no modules) | A-5764-0004 |

Single artefact kit (SFA1 and single artefact holding kit) | A-5764-0072 |

Triple artefact kit (SFA1, 2, 3 and triple artefact holding kit) | A-5764-0073 |

SFP2 probe and modules | |

SFM-A1 2 µm general purpose straight module (type A skid) | A1-D-02C90D |

SFM-A1 5 µm general purpose straight module (type A skid) | A1-D-05C90D |

SFM-A2 2 µm general purpose cranked module (type A skid) | A2-D-02C90D |

SFM-A2 5 µm general purpose cranked module (type A skid) | A2-D-05C90D |

SFM-B1 2 µm straight module with smaller skid for short lands (type B skid) | B1-D-02C90D |

SFM-B1 5 µm straight module with smaller skid for short lands (type B skid) | B1-D-05C90D |

SFM-B2 2 µm cranked module with smaller skid for short lands (type B skid) | B2-D-02C90D |

SFM-B2 5 µm cranked module with smaller skid for short lands (type B skid) | B2-D-05C90D |

SFM-B3 5 µm 90° module with smaller skid for pockets and grooves (type B skid) | B3-D-05C90D |

SFM-B4 5 µm cranked module with smaller skid for reach into confined areas (type B skid) | B4-D-05C90D |

SFM-B5 5 µm cranked module with smaller skid for reach into undercuts and grooves (type B skid) | B5-D-05C90D |

SFM-C3 2 µm straight module for small bores (type C skid) | C3-D-02C90D |

SFM-C3 5 µm straight module for small bores (type C skid) | C3-D-05C90D |

SFM-D1 2 µm 90° module for extra reach (type D skid) | D1-D-02C90D |

SFM-D1 5 µm 90° module for extra reach (type D skid) | D1-D-05C90D |

SFM-E1 2 µm long straight module with 2-part skid (type E skid) | E1-D-02C90D |

SFM-E1 5 µm long straight module with 2-part skid (type E skid) | E1-D-05C90D |

SFM-E2 5 µm long straight module with 2-part skid (type E skid) | E2-D-05C90D |

SFM-G1 Grooved engine bores prepared for PTWA coating (type G skid) | G1-D-10C30C |

SFM-H1 automatic transmission valve bodies, minimum feature access (mm): Ø9 × 122 (max. depth) (type H skid) | H1-D-02C90D |

SFM-H1 5 µm automatic transmission valve bodies, minimum feature access (mm): 9 122 (max. depth) (type H skid) | H1-D-05C90D |

Accessories | |

SFH-1 surface finish module holder | A-5764-0080 |

SFH-2 surface finish module holder | A-5764-0081 |

SFA1 3.0 SIN artefact (SFA1 plate with UKAS certificate) | A-5764-0060 |

SFA2 0.5 SIN artefact (SFA2 plate with UKAS certificate) | A-5764-0061 |

SFA3 0.4 ST artefact (SFA3 plate with UKAS certificate) | A-5764-0062 |

OFA optical flat artefact (* special product) | A-5764-3142 |

Single artefact holder mounting kit. Contains: SFAH-1 single plate holder, rack adaptor, leg adaptor, fixings for all options, tools | A-5764-0070 |

Triple artefact holder mounting kit. Contains: SFAH-2 triple plate holder, rack adaptor, leg adaptor, fixings for all options, tools | A-5764-0071 |

TFP tip find probe kit (including TP20 LF mod, stylus, PL24 cable) | A-5764-0063 |

MST module setting tool | A-5764-0091 |

System storage box | A-5764-0090 |