Enclosed optical encoders

Find your enclosed optical encoder solution

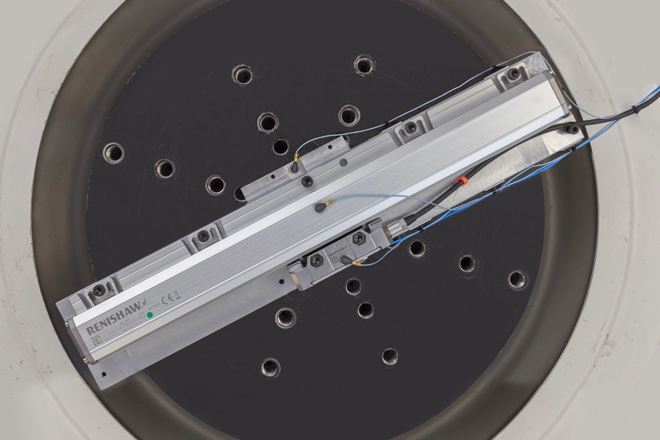

FORTiS-S™ standard size enclosed linear encoders

Featuring Renishaw's proven absolute encoder technology within an exceptionally robust enclosed design, FORTiS encoders deliver high performance measurement in the harshest of environments, offering significant benefits over conventional systems.

- Non-contact design – no mechanical wear and greater longevity

- Reduced hysteresis – smoother feedback and improved dynamic performance

- Breakthrough in readhead design – superior vibration resistance

- Uniquely sealed – greater resistance to contamination by fluids and solid debris

- Patented set-up LEDs – integral LED signal strength indicator for simple and quick installation and set-up

FORTiS-N™ narrow size enclosed linear encoders

Incorporating identical encoder technology and delivering the same benefits as the FORTiS-S models, FORTiS-N linear encoders have been designed with a more compact readhead in a narrower extrusion, making them ideally suited to applications in more confined spaces.

- Non-contact design – no mechanical wear and greater longevity

- Tuned mass damper technology delivers class leading vibration resistance

- Suitable for smaller and lighter machine designs

- Can be fastened directly to a machined surface or optional mounting spar

- Patented set-up LED for fast and intuitive right-first-time installation

Contact us to discuss your requirements

What is a Renishaw enclosed optical encoder?

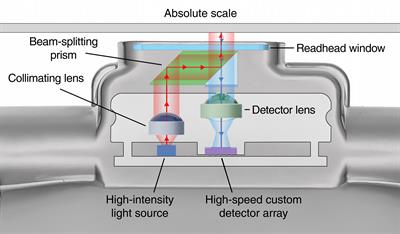

An enclosed optical encoder houses the encoder's electronics and optics within a sealed unit that is attached to a readhead body. Both the sealed optical unit and the encoder's scale are further protected within a sealed enclosure. This design provides high resistance to the ingress of liquids and solid debris contaminants.

The enclosed linear encoder features an extruded enclosure with longitudinally attached interlocking lip seals and sealed end caps. The readhead body is joined to a sealed optical unit by a blade, which travels through the lip seals along the length of the encoder.

Linear axis movement causes the readhead and optics to traverse the encoder's absolute scale (which is fixed to the inside of the enclosure), without mechanical contact.

The encoder's scale features an absolute scale code of full-width contrasting lines, which is imaged via a lens onto a detector array inside the readhead. Linear position measurements, output in digital form, are compatible with a range of industry standard serial communications protocols.

Solving mechanical vibration problems

Machine vibration can affect conventional enclosed encoders in two ways: it causes a position measurement error when the vibration frequency is close to the encoder's resonant frequency, and severe vibration may cause the encoder to signal an alarm and emergency stop the machine.

Renishaw has designed the FORTIS encoder series with several unique features that increase its robustness against vibration, such as the use of tuned mass dampers. This innovative encoder design delivers a substantial improvement in positional stability, especially at the encoder's resonant frequency, and an enhanced ability to survive extreme conditions with high levels of vibration.

For more details, see our technical white paper that explores the vibration resistance of FORTiS encoders in detail.

Easy installation that is 'right first time'

FORTIS linear encoders are designed to be installed by assembly operators, without the need for technician-level skills and equipment. The integral set-up LED provides an instant visual verification of the encoder installation, indicating if further adjustments are required and showing blue when the encoder installation is optimised.

For further assistance with installation, the optional Advanced Diagnostic Tool ADTa-100 can acquire and record comprehensive real-time encoder data, such as signal strength versus axis position. The ADTa-100 provides power to the encoder and can be connected to a Windows® tablet or a PC via a USB cable.

FORTiS encoders can be aligned and installed quickly and easily using the ultra-fast installation technique.

Reduce air purge by up to 91% on machines

Machine users adopting a smart approach to air purge with FORTiS absolute enclosed encoders can significantly reduce their attributable CO2e emissions, and lower electricity costs. Thanks to the unique use of DuraSeal™ lip seals, FORTiS encoders allow many users to employ a low flow air purge philosophy. This provides all the reliability benefits of an air purge but reduces compressed air consumption by up to 91% when compared with other enclosed linear encoders.

For more details, read our application note to find out how to reduce your carbon footprint in standard operational environments and without restrictive conditions.

Easy replacement with fit, form and function compatibility

FORTiS linear encoders are designed for easy integration in replacement of conventional linear glass scales; providing fit, form and function compatibility with the most common industry standard encoders. FORTiS encoders have the same bolt holes as these encoders and can be fitted to the same readhead bracket design, enabling quick and easy replacement of encoders that have failed on machines in the field.

The FORTiS encoder series is compatible with a wide range of industry-standard controllers, including Beckhoff, Bosch, FANUC, Mitsubishi, Num, Omron, Panasonic, Siemens, Yaskawa and more. FORTiS linear encoders offer compatible resolution options and, in many cases, plug-and-play parameter compatibility too.

Renishaw makes a range of readhead cables that can be mated to extension cables that are already routed through the machine or provide new readhead or extension cables with connectors to plug straight into the controller.

1. Industry standard resolution and accuracy options; 2. Bolt-hole compatible with industry standard encoders; 3. Industry standard measuring lengths and size format; 4. Pin compatible with popular CNC controllers