What's new for CARTO?

What new features were delivered in version 4.14?

Capture

Dynamic improvements

- Save environmental condition summary alongside dynamic test data for precise and reliable data

- Display and log environmental compensation factors from the XC-80 directly within CARTO

- You can now export dynamic test results as .CSV files, making it easy to open the test data in other software tools.

Explore

- CARTO Explore now supports XK20 test data analysis. Import .JSON files to perform straightness, parallelism, and squareness analysis.

- The home screen has been redesigned, grouping related functions together for a cleaner, more intuitive user experience.

Key features in Capture

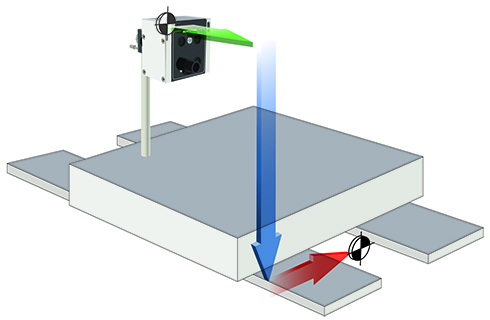

Off-axis rotary measurement mode

The off-axis rotary measurement mode in the Capture application is a licensed option which allows the XR20 rotary axis calibrator, combined with the XL-80 laser system or XM-60 multi-axis calibrator to capture off-axis measurements in one session.

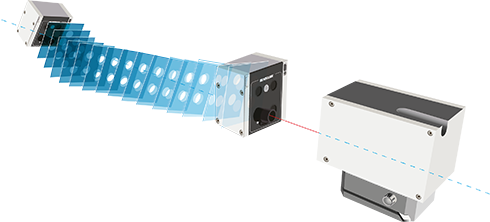

Improved straightness and long range measurement

Minimise the effects of air turbulence and vibration often observed during straightness measurement when using your XM-60 or XM-600 multi-axis calibrator. Dynamic data fit mode captures a higher density of straightness data in a continuous sweep of the axis. This method gives a more representative error for the application being measured.

Key features in Explore

Measure point of interest

Measurement at the point of interest is often not possible. The location can compromise mounting of the hardware or obstruct the laser beam. The offset readings function in Explore allows the X, Y, Z deviations from the receiver to the point of interest to be entered into the software. Captured data is then recalculated to give the true errors at the source.

Error visualisation

Understanding errors and the relationship between the 6 degrees of freedom is not always easy to interpret. The 3D error visualisation feature, with graphical plots, in Explore displays a scalable animation of the measured axis. This allows the user to gain a greater understanding of their machine and easily demonstrate error against position whilst in the error visualisation mode.

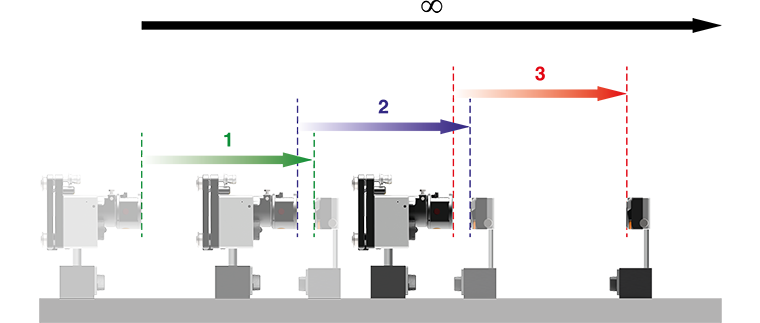

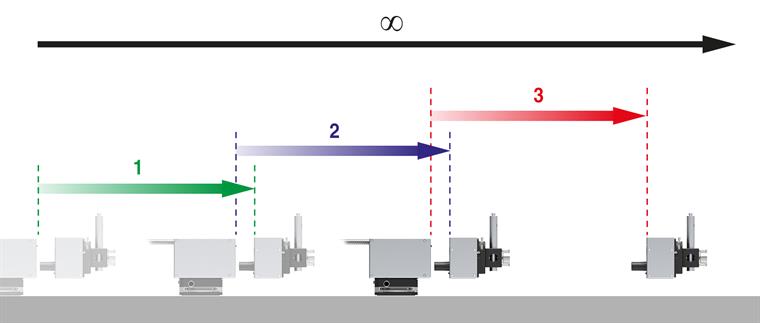

Data stitch for longer axes measurement

CARTO Explore features the data stitch function which can be used with the XM-60 system (through target-based measurement modes) and the XK10 or XK20 alignment laser systems and the XL-80 laser system to break down longer axes measurements into smaller sections and stitch them together.

By breaking the measurement into smaller sections and stitching them together, the environmental effects like air turbulence and noise, on each section can be reduced. This is done to international standards and increases the accuracy of total measurements.

XK10 system demonstrating data stitch

XM-60 system demonstrating data stitch

Want to know more?

Discover more about our intuitive CARTO software suite and CARTO add-ons. Easily access videos, user guides and downloads for more helpful information.

Delivered in version 4.13

Explore: Uncertainty analysis for data stitch tests

The new uncertainty analysis for data stitch tests provides a graphical representation of uncertainty values. This enables users to gain deeper insights into their XM-60 multi-axis calibrator, XL-80 laser or XK10 alignment laser data stitched tests.

Explore: Uncertainty analysis for dynamic data fit tests

Adding uncertainty analysis to dynamic data fit tests allows users to graphically see the uncertainty along the entire span of their test. Therefore, gaining further insight into the data they are capturing with the XM-60 multi-axis calibrator.

Delivered in version 4.12

Explore

- XK10 data stitch

- Lockable data editing

- Error visualisation - moving launch unit

- Change the locale language from application settings in Explore

- Added new analysis standard for Ballbar GB/T 17421.4 2003

Capture

- Export, import, delete a test template

- Set linear sign direction manually

- Add pilgrim and pendulum sequence to dual measurement mode

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.